Road cyclists treasure the precise handling, responsive acceleration, and lightweight efficiency that define quality road bikes. The prospect of adding electric assistance naturally raises concerns about compromising these cherished characteristics.

Can you truly electrify a road bike without destroying what makes it special? The answer is yes—but only with careful component selection, thoughtful installation, and realistic expectations about what conversion can and cannot preserve.

Converting a road bike represents perhaps the most delicate e-bike conversion challenge. Unlike robust mountain bikes or versatile gravel bikes, road bikes optimize for minimal weight, aerodynamic efficiency, and razor-sharp handling.

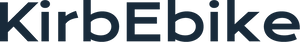

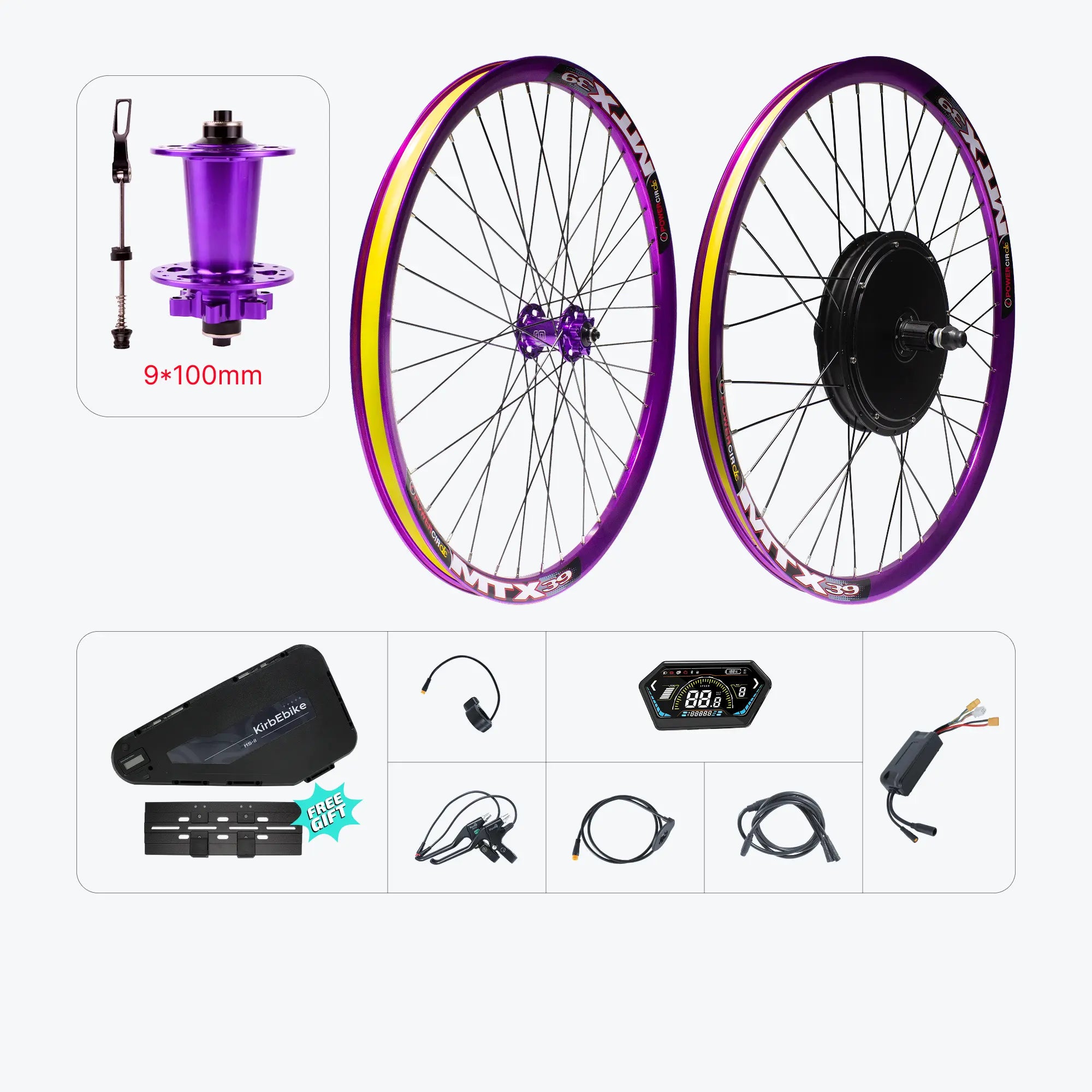

KirbEbike's conversion kit range offers solutions specifically suited to road bike applications, but success depends on understanding which compromises are acceptable and which fundamentally alter the road bike experience.

The Road Bike Conversion Philosophy

Accepting Strategic Compromises

Pure road bike performance and electric assistance exist in tension. Recognizing upfront which characteristics you're willing to trade ensures realistic expectations and prevents disappointment.

What conversion inevitably changes:

- Overall weight increases 5-10kg minimum

- Acceleration response becomes less immediate

- Wheel inertia affects cornering feel

- Frame aesthetics gain visible components

- Simplicity transforms into complexity

What conversion can preserve:

- Geometry and rider position

- Quality component compatibility

- Adequate climbing and cruising capability

- Reasonable efficiency for extended rides

- Sufficient handling precision for most applications

Identifying Appropriate Candidate Bikes

Not every road bike suits conversion equally. Frame characteristics dramatically impact final results.

Best road bike conversion candidates:

Endurance Road Bikes

- Relaxed geometry tolerates weight addition better

- Tire clearance accommodates motor installation

- Mounting points for racks/fenders support battery options

- Disc brakes handle increased speeds

- Aluminum or steel frames provide strength

Touring Road Bikes

- Built for loaded riding (frame strength adequate)

- Multiple bottle cage bosses ease battery mounting

- Sturdy wheels handle motor weight

- Long chainstays provide installation clearance

- Already optimized for efficiency over pure speed

Flat-Bar Road Bikes

- Upright position suits electric assist philosophy

- Generous tire clearance simplifies installation

- Less aesthetic concern about added components

- Typically more robust frame construction

Problematic road bike candidates:

Racing Road Bikes

- Ultra-lightweight frames risk structural issues

- Narrow tire clearance limits motor options

- Minimal mounting points complicate battery placement

- Geometry unsuited to added weight

- Aesthetic impact particularly severe

Carbon Fiber Road Bikes

- Manufacturer warranties void upon conversion

- Frame not designed for motor stress patterns

- Difficult battery mounting without proper bosses

- Expensive frames risk devaluation

- Safety concerns with motor torque on carbon

Motor Selection That Respects Road Bike Character

Hub Motor Approaches for Road Bikes

Rear Hub Motors: The Logical Choice

Rear wheel hub motors provide the most road-bike-appropriate electric assistance when carefully selected.

Advantages for road applications:

- Power delivery through rear wheel (traditional road bike feel)

- Independent of drivetrain (preserves shifting quality)

- Sealed construction requires minimal maintenance

- Silent operation maintains road cycling ambiance

- Easier wheel-off for transport than mid-drive

Critical power level selection:

|

Road Bike Type |

Maximum Recommended Power |

Rationale |

|

Lightweight race bikes |

250-500W |

Frame strength limits, weight concerns |

|

Endurance road bikes |

500-750W |

Balanced capability without excess |

|

Touring/adventure road |

750-1000W |

Frame strength adequate, utility focused |

|

Flat-bar fitness bikes |

750-1000W |

Robust frames, practical orientation |

Why front hub motors fail for road bikes:

Front hub motors fundamentally compromise road bike handling:

- Weight distribution destroys precise steering feel

- Reduces front wheel feedback through corners

- Climbing traction concerns on steep grades

- Fork stress inappropriate for road bike forks

- Aesthetic impact particularly jarring

Mid-Drive Conversion Considerations

Mid-drive systems like the KirbEbike Tongsheng TSDZ8 offer theoretical advantages but present significant road bike challenges.

Mid-drive benefits for road bikes:

- Centered weight preserves handling balance

- Leverages gear range for efficiency

- Maintains quick-release wheel convenience

- Professional appearance possible with clean installation

Mid-drive complications for road bikes:

- Accelerated drivetrain wear (chains, cassettes costly)

- Installation complexity with integrated bottom brackets

- Chainline issues with road bike gearing

- Potential front derailleur interference

- Noise from motor/drivetrain interaction

When mid-drives make sense:

Consider mid-drive for road bikes only when:

- Significant climbing dominates your routes

- Frame has traditional threaded bottom bracket

- Budget accommodates increased drivetrain maintenance

- Willing to upgrade to e-bike specific chains/cassettes

- Prioritizing efficiency over simplicity

Battery Integration That Maintains Aesthetics

The Downtube Battery Approach

Downtube mounting represents the standard for converted road bikes, offering the best compromise between aesthetics and functionality.

Installation requirements:

Frame compatibility verification:

- Water bottle cage mounting holes present

- Adequate clearance from crankset (75mm minimum)

- Sufficient tube diameter (45-50mm ideal)

- Reasonable ground clearance preserved

- Room for cables without fouling components

Capacity selection for road bike applications:

Road riding typically demands less battery capacity than mountain biking due to smooth surfaces and aerodynamic efficiency.

|

Ride Type |

Typical Distance |

Recommended Capacity |

Battery Voltage |

|

Local rides/commuting |

30-50km |

300-500Wh |

36V 10-13Ah |

|

Club rides |

50-80km |

500-700Wh |

48V 11-15Ah |

|

Gran fondo/events |

80-120km |

700-900Wh |

48V 15-20Ah |

|

Touring/ultra distance |

120km+ |

900-1200Wh |

52V 20-25Ah |

Browse KirbEbike's battery collection for road-appropriate capacity options with sleek downtube form factors.

Alternative Battery Mounting Solutions

Seat Tube Mounting

Some road bikes lack adequate downtube space but offer seat tube mounting possibilities.

Advantages:

- Lower center of gravity than downtube

- Can work with challenging frame shapes

- Maintains one bottle cage location

Limitations:

- Requires seat tube bottle bosses

- Reduces standover clearance

- May interfere with rear fender

- Less common battery form factors

Frame Bag Battery Options

Custom frame bags containing batteries provide maximum flexibility for unusual road bike frames.

Best applications:

- Bikes lacking any bottle cage mounts

- Temporary conversions (removable for racing)

- Compact battery solutions for minimal impact

- Preserving aesthetic purity of special frames

Considerations:

- Takes valuable storage space

- Can interfere with frame pump mounting

- Requires quality waterproof construction

- Weight positioned higher than downtube mount

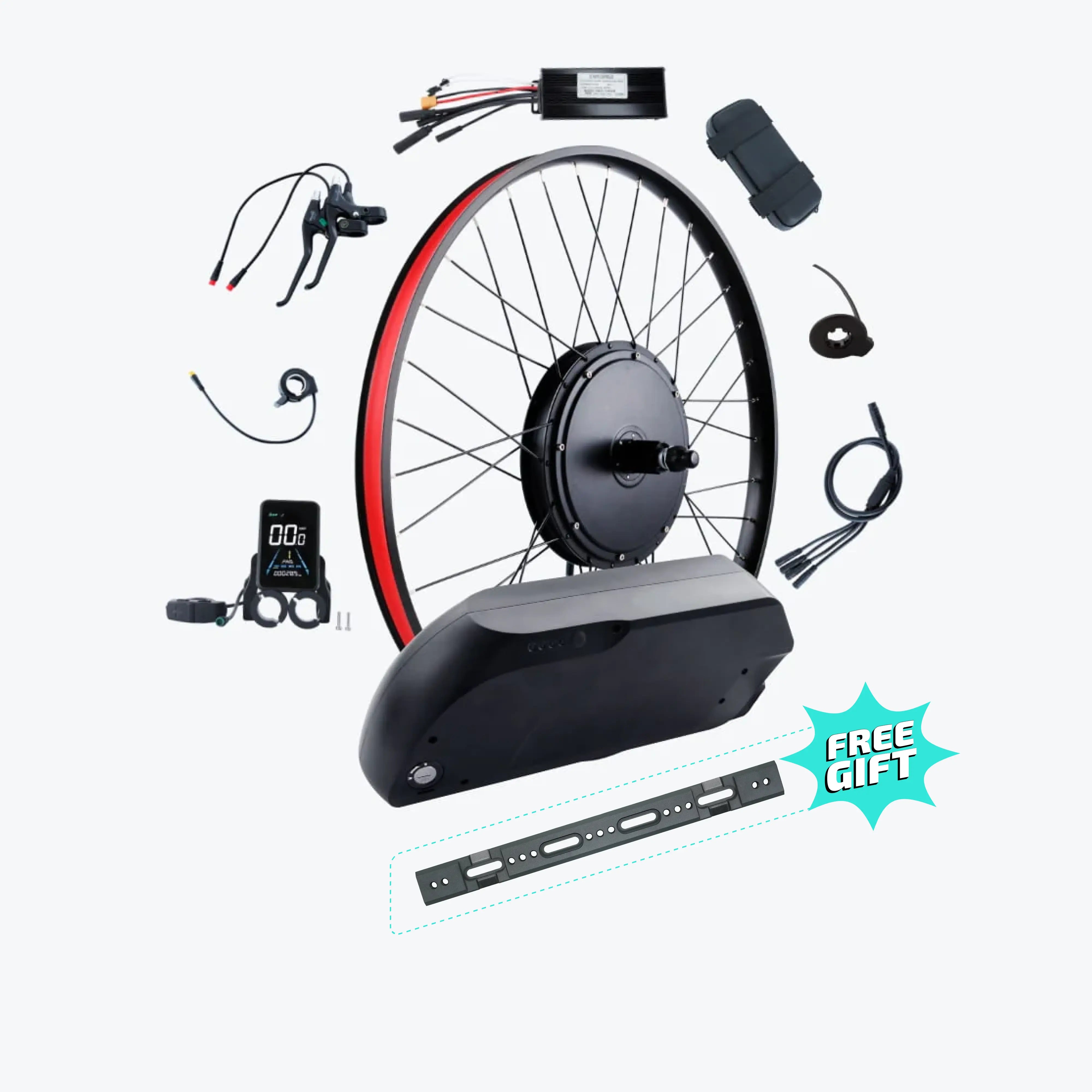

The Aesthetic Challenge

Road bikes' clean lines and purposeful appearance suffer visibly from conversion hardware. Minimizing visual impact requires deliberate choices.

Aesthetic preservation strategies:

Cable routing:

- Follow existing cable paths where possible

- Use spiral wrap matching frame color

- Minimize zip tie visibility with careful placement

- Consider partial internal routing for cleaner appearance

Component selection:

- Match motor finish to wheel color (black/silver)

- Choose slim battery profiles over bulky alternatives

- Select compact displays or smartphone integration

- Avoid external controller boxes when possible

Battery aesthetics:

- Downtube batteries resembling water bottles blend best

- Consider battery wraps matching frame color

- Position battery to align with frame tubes

- Use proper mounting hardware (not hose clamps)

Component Upgrades for Safe Conversion

Brake System Requirements

Road bike brakes designed for 7-8kg bikes and 30km/h speeds may inadequately stop 13-15kg bikes reaching 40-45km/h.

Rim brake limitations:

Traditional rim brakes on road bikes present serious safety concerns after conversion:

- Insufficient stopping power for added weight/speed

- Brake track overheating on long descents

- Pad wear accelerated dramatically

- Wet weather performance dangerously reduced

Disc brake advantages:

Road bikes with disc brakes handle conversion far better:

- Adequate power for weight and speed increases

- Consistent performance in all conditions

- Less wheel damage from braking forces

- Room for larger rotors if needed

Brake upgrade decision matrix:

|

Original Brake Type |

Conversion Power |

Required Action |

|

Rim brakes |

<500W |

Acceptable with caution, upgrade pads |

|

Rim brakes |

500-750W |

Strongly recommend disc brake frame |

|

Rim brakes |

750W+ |

Do not convert—unsafe |

|

Mechanical disc |

Any power |

Acceptable, consider hydraulic upgrade |

|

Hydraulic disc |

Any power |

Ideal, possibly upgrade rotors |

Drivetrain Considerations

Hub Motor Systems:

Standard road bike drivetrains work perfectly with hub motors since power bypasses the chain entirely. No upgrades required beyond normal maintenance.

Mid-Drive Systems:

Significant upgrades mandatory for longevity:

Essential components:

- E-bike specific chains (stronger pins, wider plates)

- All-steel cassettes avoiding aluminum cogs

- Narrow-wide chainrings preventing drops

- More frequent maintenance schedule

Realistic wear expectations:

- Chain replacement: 1500-2500km (vs. 4000-6000km normal)

- Cassette replacement: 3000-5000km (vs. 10,000-15,000km normal)

- Chainring replacement: 5000-8000km (vs. 15,000km+ normal)

Budget accordingly—mid-drive maintenance costs add up significantly.

Final Decision Framework

Successfully converting a road bike without ruining ride feel requires realistic expectations and careful execution. Explore KirbEbike's complete conversion kit range to find components matched to road bike characteristics—lightweight, efficient, and thoughtfully designed.

Critical success factors:

- Choose appropriate base bike (endurance geometry, disc brakes, robust frame)

- Select modest power levels (250-750W maintains road bike character)

- Prioritize weight distribution (downtube batteries, rear hub motors)

- Upgrade brakes if necessary (safety absolutely essential)

- Accept handling changes (conversion alters feel—this is inevitable)

- Maintain diligently (converted bikes require enhanced care)

Road bike conversion represents compromise between pure cycling purity and practical electric assistance. Done thoughtfully, converted road bikes deliver meaningful capability extension without completely destroying the characteristics that made the original bike appealing. Understanding what you're gaining and what you're sacrificing ensures satisfaction with your converted road bike.

Frequently Asked Questions

Will converting my road bike make it too heavy for normal riding?

Weight increase of 5-10kg is typical, roughly doubling a lightweight road bike's weight. Most riders adapt within weeks, though acceleration and climbing feel different. The motor compensates on hills, making the net effect less severe than static weight suggests.

Can I still ride with my cycling club after converting my road bike?

Yes, if motor assistance is subtle and you match group pace without excessive motor use. Choose quiet hub motors over louder mid-drives. Some clubs prohibit motorized bikes, so verify policies. Many riders successfully participate using minimal assist to maintain fitness.

Should I convert my carbon fiber road bike or buy a cheaper aluminum bike for conversion?

Convert a cheaper aluminum or steel bike instead. Carbon fiber conversion voids warranties, risks frame damage from motor stress, and devalues expensive frames significantly. Purchase affordable used aluminum endurance road bikes specifically for conversion projects.

What power level lets me keep up with faster riders without ruining handling?

500-750W provides substantial assistance while maintaining reasonable handling. This power range helps bridge gaps to faster groups without overwhelming road bike geometry. Higher power levels increasingly compromise handling precision that makes road bikes enjoyable.

How much does road bike conversion affect aerodynamics?

Battery, motor, and cables add modest aerodynamic drag, but impact is small compared to rider position. At typical e-bike speeds (30-35km/h), aerodynamic losses are negligible. For serious racing where every watt matters, conversion proves impractical regardless.

Can I convert a road bike with electronic shifting (Di2/eTap)?

Yes, electronic shifting and conversion work together, though installation complexity increases with additional wiring. Hub motors prove simpler than mid-drives. Ensure motor controller doesn't interfere with shifting signals. Some riders report improved shifting under motor power assist.

Will my road bike frame handle the stress of motor power long-term?

Quality aluminum and steel endurance/touring road frames handle 500-750W conversions well. Lightweight race frames risk issues. Regular inspection for cracks crucial, particularly around dropouts, bottom bracket, and downtube mounting areas. Avoid converting questionable or damaged frames.