Cargo bikes revolutionize urban transportation by replacing car trips with human-powered hauling, but their primary limitation—the physical effort required to move substantial loads—keeps many potential users relying on automobiles.

Electric conversion transforms cargo bikes from admirable but exhausting alternatives into genuinely practical car replacements. However, converting a cargo bike demands fundamentally different considerations than converting standard bicycles.

The structural stresses, weight distribution challenges, and safety implications of motorizing load-carrying bikes require specialized knowledge that prevents dangerous mistakes.Unlike recreational bike conversions where performance and aesthetics dominate priorities, cargo bike electrification centers entirely on safe, reliable heavy-load transportation.

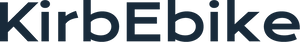

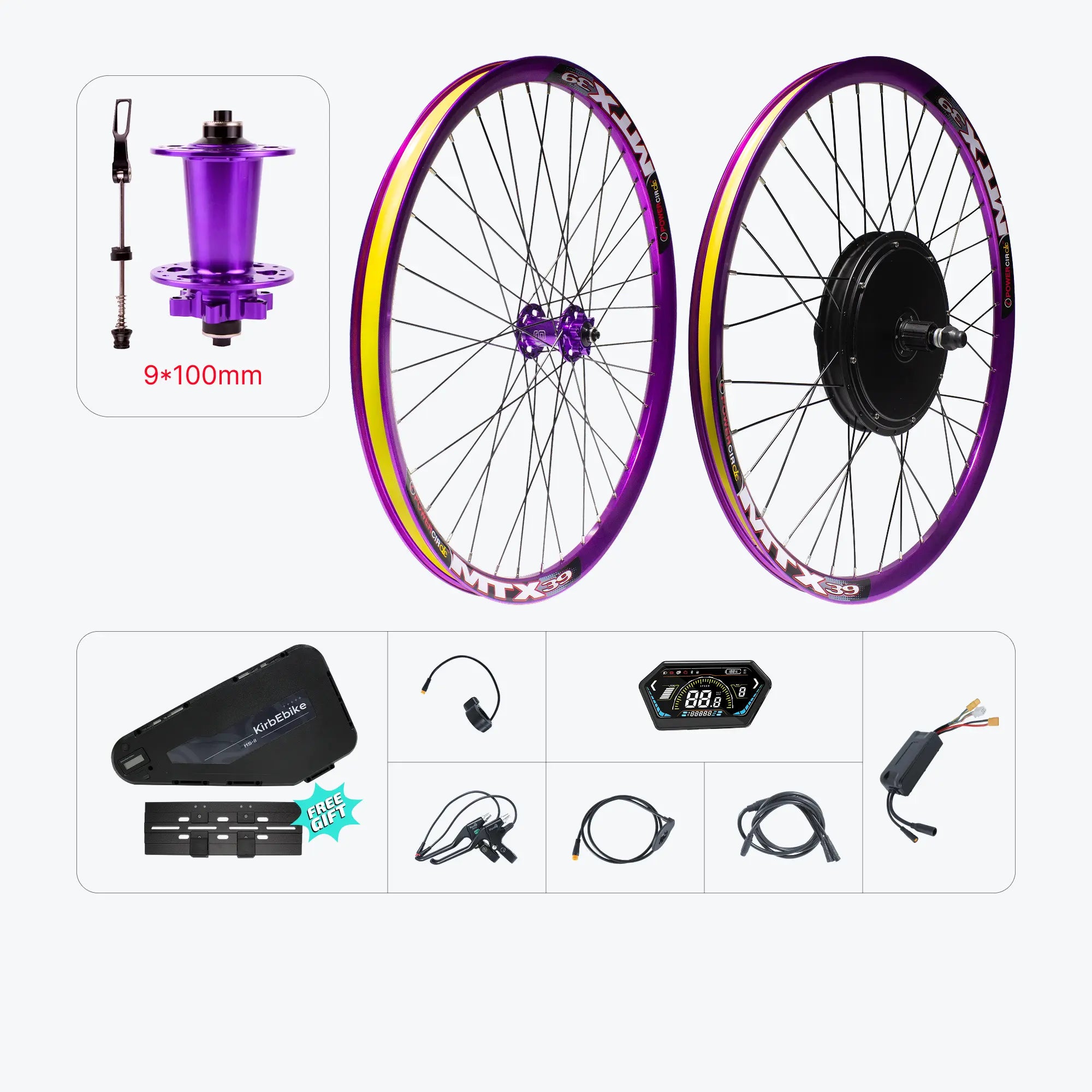

A family carrying two children, groceries, and cargo needs absolute confidence in their conversion's mechanical integrity. KirbEbike's powerful conversion systems provide the robust components cargo bikes require, but successful implementation depends on understanding load-specific motor selection, reinforced mounting techniques, and capacity-appropriate battery sizing that matches cargo bike demands.

Understanding Cargo Bike Conversion Requirements

Cargo Bike Categories and Conversion Implications

Longtail Cargo Bikes

Extended rear rack designs carrying passengers and cargo behind the rider present specific conversion opportunities and challenges.

Structural characteristics:

- Reinforced rear triangle handles substantial loads

- Extended wheelbase improves stability under weight

- Typically 26" or 20" rear wheels

- Strong mounting points for racks and accessories

- Often feature kickstands rated for loaded weight

Conversion advantages:

- Rear hub motors mount to already-reinforced dropouts

- Weight distribution maintains with rear motor placement

- Battery mounting options abundant on extended frames

- Passengers benefit from smooth electric acceleration

Front-Loading Cargo Bikes (Bakfiets/Long John style)

Low center of gravity box bikes with cargo area ahead of rider demand careful motor placement.

Structural characteristics:

- Small front wheel (typically 20") with low cargo box

- Extended frame connecting steering to front wheel

- Rider positioned behind cargo area

- Rear wheel (26" or 28") bears majority of drive force

- Extremely stable platform when properly loaded

Conversion considerations:

- Rear hub motors ideal (front wheel too small for powerful motors)

- Mid-drive systems work excellently with appropriate gearing

- Battery placement flexible due to frame size

- Low speed but high torque requirements

Midtail Cargo Bikes

Compromise designs between standard bikes and longtails offer moderate cargo capacity with less bulk.

Characteristics:

- Slightly extended rear for child seats or moderate cargo

- More maneuverable than full longtails

- Typically standard wheel sizes (26" or 700c)

- Less structural reinforcement than dedicated cargo bikes

Conversion approach:

- Hub motors rated for increased weight essential

- Battery capacity sized for both rider and typical cargo

- Torque arms mandatory given load stress

- Brake upgrades critical

Load Capacity Calculations

Accurate weight assessment prevents motor overloading and frame damage.

Total system weight components:

|

Component |

Typical Weight |

Notes |

|

Base cargo bike |

20-35kg |

Varies by construction and accessories |

|

Motor system |

4-7kg |

Hub motors toward higher end |

|

Battery |

2-5kg |

Capacity dependent |

|

Rider |

60-100kg |

Individual variation |

|

Passengers (children) |

15-40kg |

Age dependent, 1-2 children typical |

|

Cargo/groceries |

10-30kg |

Weekly shopping, bags, equipment |

|

Total loaded weight |

111-217kg |

Maximum realistic scenario |

Motor and component selection must accommodate these substantial total weights.

Motor Selection for Cargo Bike Applications

Power Requirements for Load Hauling

Cargo bikes demand significantly more power than passenger bikes, particularly for hill climbing with full loads.

Power recommendations by terrain and load:

|

Typical Load |

Flat Urban |

Rolling Hills |

Steep Climbs |

|

Light (rider + 20kg) |

500-750W |

750-1000W |

1000-1500W |

|

Moderate (rider + 40kg) |

750-1000W |

1000-1500W |

1500-2000W |

|

Heavy (rider + 60kg+) |

1000-1500W |

1500-2000W |

2000W+ |

Why higher power matters for cargo:

Hill climbing capability:

- 500W motors struggle with 150kg+ total weight on 8%+ grades

- 1000W systems handle moderate hills with full family loads

- 1500-2000W provides confident climbing even heavily loaded

- Inadequate power creates dangerous slow-speed instability on hills

Acceleration and traffic safety:

- Quick acceleration from stops essential with children aboard

- Traffic gap crossing requires adequate power reserves

- Stop-and-go urban riding demands responsive motor delivery

- Underpowered systems create hazardous traffic situations

Hub Motor vs. Mid-Drive for Cargo Bikes

Rear Hub Motors: The Cargo Bike Standard

Direct-drive rear hub motors provide cargo bike advantages that outweigh mid-drive benefits in most applications.

Why hub motors excel for cargo:

Simplicity and reliability:

- Sealed motors require minimal maintenance

- No additional drivetrain stress (critical with heavy loads)

- Standard chains and cassettes work indefinitely

- Fewer failure points for family transportation

Power delivery characteristics:

- Direct power to rear wheel (intuitive for cargo handling)

- Smooth, predictable assistance (important with passengers)

- Independent of gear selection (simple operation)

- Regenerative braking possible (extends range, reduces brake wear)

Mounting considerations:

- Cargo bikes feature reinforced rear dropouts designed for load

- Torque arms distribute motor stress appropriately

- Rear position maintains weight distribution balance

- Doesn't interfere with front cargo box designs

Mid-Drive Systems: Specialized Cargo Applications

Mid-drive conversions like the KirbEbike Tongsheng TSDZ8 suit specific cargo bike scenarios despite drawbacks.

When mid-drives make sense:

Extreme hill climbing:

- Gear leverage provides maximum climbing torque

- Essential for San Francisco-level grades with heavy loads

- Efficiency advantages extend range on challenging terrain

Smaller wheel compatibility:

- Works with any wheel size including 20" cargo bike wheels

- Front-loading bikes with tiny front wheels need rear mid-drive

- Preserves quick-release wheel convenience

Mid-drive cargo bike challenges:

Accelerated component wear:

- Chains wear 3-5x faster under cargo load and motor power

- Cassettes require frequent replacement

- Higher ongoing maintenance costs for family transportation

- Potential for mechanical failure when reliability is paramount

Installation complexity:

- Bottom bracket installation more involved than hub motor

- Cargo bike frame modifications sometimes necessary

- Professional installation recommended for family-carrying bikes

Essential Safety Upgrades for Converted Cargo Bikes

Brake System Requirements

Standard bicycle brakes prove catastrophically inadequate for heavy cargo bikes, particularly electric ones reaching higher speeds.

Minimum brake specifications for converted cargo bikes:

|

Total Loaded Weight |

Minimum Brake Type |

Recommended Configuration |

|

Under 100kg |

Hydraulic disc, 160mm |

180mm front, 160mm rear |

|

100-150kg |

Hydraulic disc, 180mm |

180mm front/rear or 203mm front |

|

150-200kg |

Hydraulic disc, 180mm+ |

203mm front, 180mm rear, 4-piston calipers |

|

200kg+ |

Heavy-duty hydraulic |

203mm both wheels, 4-piston, metallic pads |

Critical brake considerations:

Stopping distance with cargo:

- Loaded cargo bikes require 30-50% more stopping distance than unloaded

- Electric assistance increases average speeds further extending stops

- Emergency stops with children aboard demand immediate response

- Brake fade from repeated stops poses serious danger

Component upgrades:

- Larger rotors increase heat dissipation and power

- Metallic pads outperform organic compounds for cargo

- Four-piston calipers provide superior modulation and power

- Hydraulic lines eliminate cable stretch issues

Tire and Wheel Durability

Standard wheels and tires collapse under cargo bike loads accelerated by motor power.

Wheel specifications for converted cargo bikes:

Spoke count and construction:

- Minimum 36 spokes for cargo applications

- 40+ spokes ideal for heavy commercial use

- Three-cross lacing pattern for strength

- Stainless steel spokes resist corrosion

- Properly tensioned for load bearing

Rim selection:

- Double-wall minimum, triple-wall preferred

- Reinforced spoke holes prevent pulling through

- Aluminum for standard use, steel for extreme applications

- Wide internal width supports larger tires

Tire requirements for motor-assisted cargo:

Load capacity and construction:

- Tires specifically rated for cargo bike loads

- Reinforced sidewalls resist punctures and cuts

- Minimum 2.0" width for load distribution

- Higher TPI for comfort without sacrificing durability

Pressure management:

- Run higher pressures than standard bikes (50-65 PSI typical)

- Adjust pressure for actual loaded weight

- Check before every ride when carrying passengers

- Consider pressure monitoring for commercial applications

Structural Reinforcement

Motor torque combined with cargo loads stresses frames beyond design specifications without reinforcement.

Torque arm installation:

Absolutely mandatory for hub motor cargo conversions—never optional.

Proper torque arm technique:

- Use dual torque arms (both sides) for 1000W+ systems

- Mount to frame or fork, not just dropout

- Distribute force across wide frame area

- Regularly inspect for movement or cracking

- Use quality steel arms, not aluminum

Frame inspection protocol:

Pre-conversion assessment:

- Examine all welds for cracks or damage

- Check dropout alignment and thickness

- Verify rack mount strength and condition

- Look for previous stress damage

- Consider professional inspection for older bikes

Ongoing monitoring:

- Monthly frame inspection when used for family transport

- Especially examine dropout area, bottom bracket, head tube

- Any cracking requires immediate professional evaluation

- Never continue using questionable frames with passengers

Planning Your Cargo Bike Conversion

Successfully electrifying a cargo bike without compromising safety requires systematic planning addressing these critical factors:

Safety-First Approach:

- Frame integrity verification through professional inspection if bike older or used intensively

- Brake system upgrade to hydraulic disc with appropriately sized rotors

- Wheel and tire assessment ensuring adequate strength for loads

- Motor power matching terrain and typical loads (don't underpower)

- Battery capacity eliminating range anxiety for actual use patterns

- Torque arm installation with dual arms for peace of mind

- Professional installation consideration for family transport applications

Component Priority:

- Brakes deserve highest budget allocation (safety paramount)

- Motor power second priority (adequate power prevents dangerous situations)

- Battery capacity third (convenience and practicality)

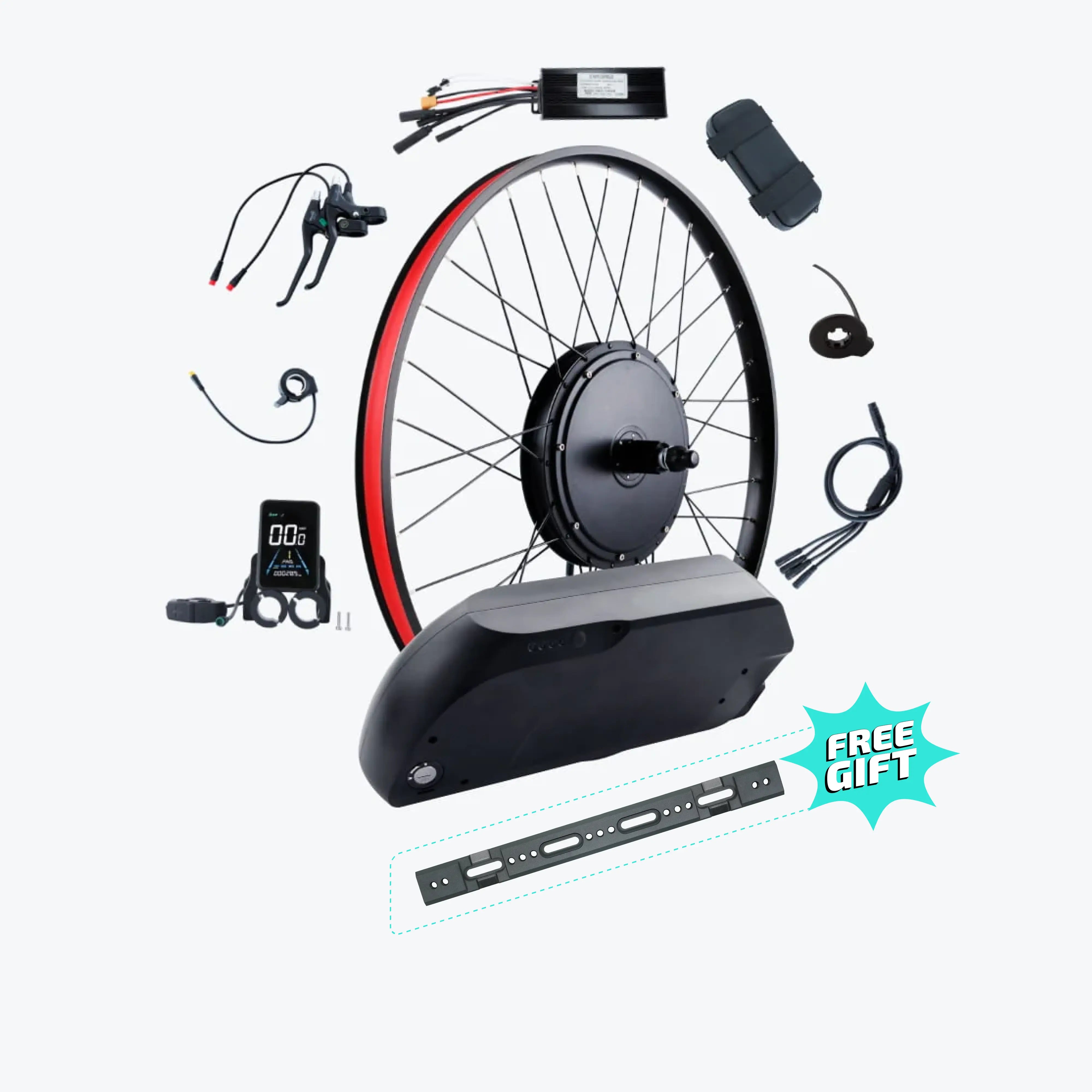

- Accessories last (lights, locks, cargo accessories)

Cargo bikes electrified thoughtfully transform family transportation, eliminating countless car trips while providing practical, safe hauling capability. KirbEbike's robust conversion systems deliver the power and reliability cargo applications demand, but successful conversion depends on prioritizing safety over cost, adequately sizing components for loads, and maintaining converted bikes with the diligence family transportation deserves.

Frequently Asked Questions

What minimum motor power do I need for a cargo bike carrying two children?

For two children (30-40kg) plus rider and cargo, minimum 1000W for flat terrain, 1500W for hilly areas. Underpowered systems create dangerous slow-speed wobbling on inclines and inadequate traffic acceleration. Size motor for your steepest regular hill fully loaded, not average conditions.

Can I convert my front-loading bakfiets cargo bike or should rear-drive only?

Rear-drive strongly recommended for front-loading cargo bikes. The small front wheels (typically 20") limit motor options, and front weight distribution demands rear power delivery. Either rear hub motor or mid-drive works well depending on terrain and preference.

How much range should I expect with 50kg of cargo plus rider?

Realistic expectations: 30-45km per 500Wh battery capacity with moderate assist on flat terrain. Hills reduce this to 20-35km. For daily cargo bike use, size battery for 2-3 days of typical use between charges to avoid range anxiety and weather charging delays.

Do I need special wheels for converted cargo bikes?

Standard wheels fail under cargo bike loads with motor power. Minimum 36-spoke wheels with reinforced rims essential. Most converted cargo bikes benefit from wheels specifically built for e-cargo use with appropriate spoke count, rim strength, and proper tensioning for load bearing.

Should I install dual batteries on my cargo bike?

Dual batteries make sense for: all-day commercial use, extremely long commutes (40km+), or eliminating all range concerns. For typical family cargo use (school runs, shopping), single 750-1000Wh battery suffices. Dual batteries add cost, weight, and complexity without benefit for moderate use.

What brake upgrades are mandatory for cargo bike conversion?

Hydraulic disc brakes with 180mm+ rotors absolutely mandatory for any cargo bike carrying passengers or heavy loads. Standard rim brakes or mechanical disc brakes dangerously inadequate. Budget substantial money for quality hydraulic brakes—this investment protects your family and is non-negotiable.

Can I convert a cargo trike or do trikes need special consideration?

Cargo trikes convert excellently due to inherent stability with loads. Use rear hub motors on rear axle (typically with differential for turning), or mid-drive on single-speed or internally geared hubs. Trikes' low center of gravity and stability make them ideal electric cargo platforms with proper motor selection.