Choosing between front-wheel and rear-wheel motor placement represents one of the most consequential decisions in e-bike conversion, fundamentally affecting installation complexity, handling characteristics, traction performance, drivetrain interaction, and overall riding experience in ways that make one configuration dramatically superior for specific applications while creating significant compromises for others.

Understanding which best ebike kit motor placement serves your particular cycling needs, terrain conditions, mechanical comfort level, and performance priorities requires examining real-world performance differences, honest assessment of trade-offs, and clear-eyed evaluation of marketing claims versus actual riding experience across varied conditions rather than assumptions about theoretical advantages disconnected from practical cycling realities.

Front-Wheel Hub Motor Systems

Installation Simplicity Advantage

Why Front Installation Remains Easiest:

Front-wheel conversions require only wheel replacement without touching drivetrain components—this fundamental simplicity creates the lowest barrier to e-bike ownership:

Installation Process (20 Minutes):

- Remove front wheel (quick-release or thru-axle)

- Install motor wheel (same dropout spacing)

- Mount display on handlebar

- Attach brake sensors to levers

- Mount battery (frame or rack)

- Connect all cables (controller integrated)

- Test system and ride

Why So Simple:

- No cassette transfer needed (major time savings)

- No derailleur adjustment required (eliminates complexity)

- No chain management necessary (huge simplification)

- Dropout spacing standard (100mm front universal)

- Torque arms often unnecessary (low power typical)

Universal Compatibility

Works With Any Drivetrain:

Front motors never interact with your bicycle's gear system:

✓ Derailleur systems (3x9, 2x11, 1x12, any configuration) ✓ Internal gear hubs (Shimano Alfine, Rohloff, Sturmey-Archer) ✓ Single-speed bicycles (fixie, beach cruiser, simple bikes) ✓ Belt drive systems (Gates Carbon Drive compatible) ✓ Any gear arrangement imaginable (zero interaction)

Why This Matters:

Riders with unusual drivetrains (internal hubs, belt drives, vintage systems) find front-wheel conversion the only practical electric option maintaining their preferred gear system without compatibility concerns.

Complete Reversibility

Return to Stock Configuration:

Front-wheel conversions reverse completely in 10-15 minutes:

- Reinstall original front wheel (store motor wheel)

- Remove display, sensors, battery (20 screws maximum)

- Bicycle returns to 100% original condition

- No permanent modifications made

- Resale value preserved

- Try electric cycling risk-free

Use Cases:

- Rental bikes (owner permission granted)

- Borrowed bicycles (temporary conversion)

- Testing electric concept (before commitment)

- Seasonal use (winter storage, summer electric)

- Travel (ship motor wheel separately, convert on arrival)

Front-Wheel Disadvantages

Traction Limitations:

Front-wheel-drive creates inherent traction challenges:

Weight Distribution Problem:

- Motor weight (2.7-4.5kg) plus battery (2.5-3.5kg) shifts forward

- Acceleration transfers weight rearward (reduces front traction)

- Hills shift weight rearward (further front traction loss)

- Wet conditions magnify traction deficit

- Front wheel slip possible (power application, cornering)

Power Ceiling:

- Practical Maximum: 500W (occasionally 750W careful use)

- Beyond 500W: Front traction inadequate (wheel spin common)

- High Power Needs: Rear wheel mandatory

- Design Limitation: Physics constraint unavoidable

Steering and Handling:

Additional front-end weight affects bicycle dynamics:

- Steering heavier initially (motor adds 2.7-4.5kg unsprung weight)

- Cable management critical (must allow full steering rotation)

- Front-heavy feeling first 50-200km (adaptation occurs)

- Technical maneuvering altered (MTB riders notice most)

- Road feel changed (pavement feedback dampened)

Rear-Wheel Hub Motor Systems

Superior Traction

Weight Distribution Advantage:

Rear-wheel-drive aligns with physics favoring rear traction:

Why Rear Traction Excels:

- Acceleration shifts weight rearward → increases rear wheel loading

- Climbing shifts weight rearward → maximizes rear traction

- Human body position over rear wheel → natural weight placement

- Motor torque directly to traction wheel → no power waste

- Rear tire larger contact patch → better grip

Performance Impact:

- Steep hills conquered (no wheel slip concerns)

- Wet conditions managed (adequate traction maintained)

- Loose surfaces capable (gravel, dirt, sand)

- Heavy loads handled (cargo, touring, utility)

- High power delivered (1000-4000W possible)

Natural Bicycle Handling

Familiar Dynamics:

Rear motor weight positioned low and central maintains traditional bicycle handling:

- Front wheel unweighted (responsive steering preserved)

- Weight centralized (low center of gravity)

- Suspension unaffected front (MTB applications)

- Cable routing simpler (less steering interference)

- Professional feel maintained (closest to traditional bicycle)

Rear-Wheel Disadvantages

Installation Complexity:

Rear wheel conversion requires drivetrain interaction:

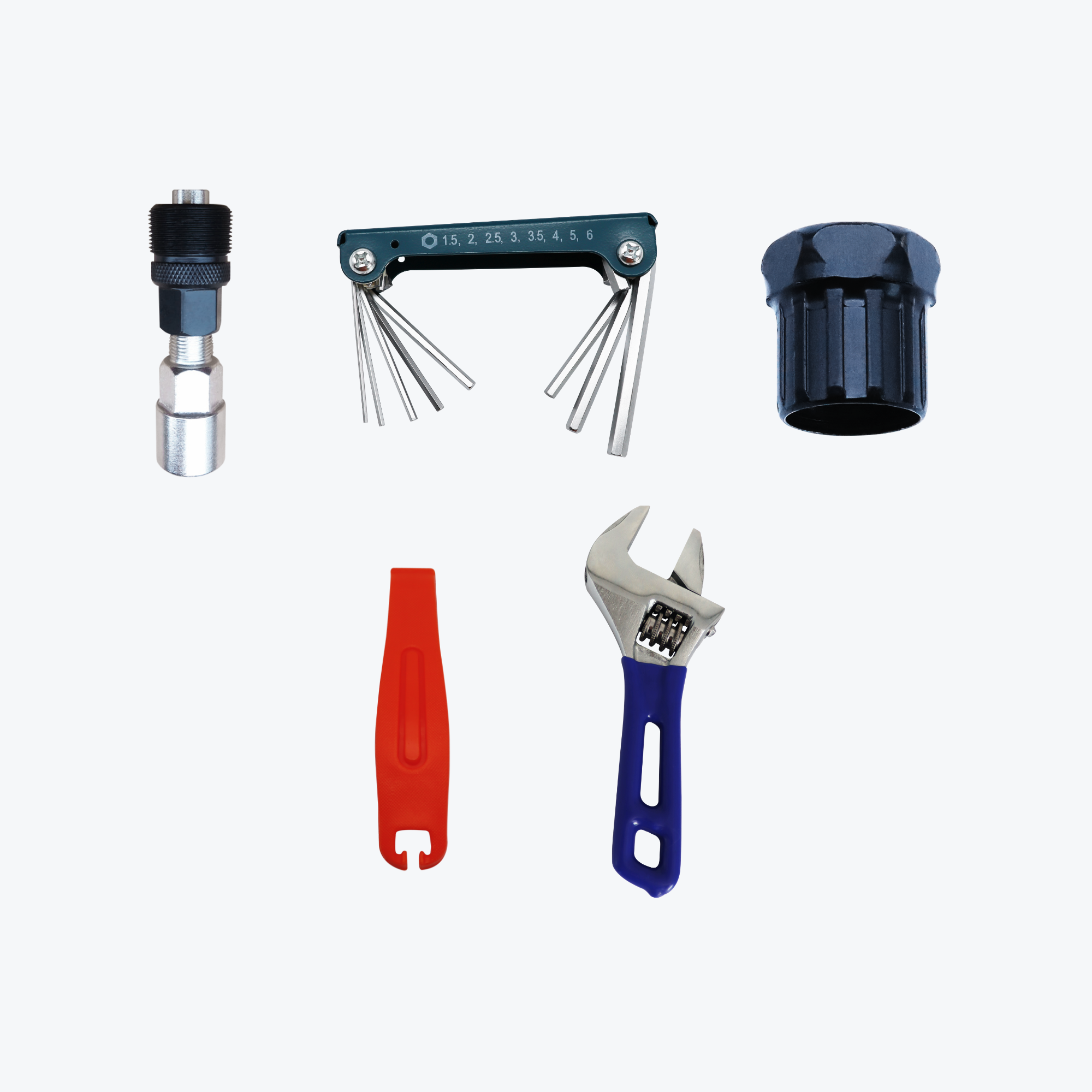

Additional Steps (25-30 Minutes):

- Remove rear wheel (derailleur, brake, chain)

- Transfer cassette to motor wheel (cassette tool required, included)

- Adjust derailleur (limit screws, cable tension)

- Route chain properly (length usually adequate)

- Install torque arm(s) (750W+ mandatory)

- Align wheel carefully (chain line, disc brake)

- Test all gears thoroughly

Why More Complex:

- Cassette transfer required (10 minutes, special tool)

- Derailleur adjustment necessary (tuning skills needed)

- Torque arms essential high power (safety critical)

- Wheel alignment fussier (brake and chain considerations)

- Skills moderate (vs basic front installation)

Drivetrain Wear Consideration:

Rear motor doesn't increase chain wear (unlike mid-drive) but considerations exist:

- Standard bicycle drivetrain wear (same as non-electric)

- Higher speeds sustained (may reduce cassette life modestly)

- More frequent riding (increased annual mileage = normal wear accumulation)

- Quality components last (LBS cassettes outlast economy)

- Maintenance standard (normal bicycle upkeep adequate)

Less Reversible:

Rear conversion more involved to reverse:

- Cassette transfer back to original wheel (10 minutes)

- Derailleur readjustment (5 minutes)

- Torque arm removal (if installed)

- Total reversal time: 25-30 minutes (vs 10-15 front)

- Still achievable but less casual

Comprehensive Comparison Table

|

Factor |

Front-Wheel Motor |

Rear-Wheel Motor |

Winner |

|

Installation Time |

20 minutes |

25-30 minutes |

Front (simpler) |

|

Mechanical Skill |

Basic |

Moderate |

Front (easier) |

|

Traction Dry |

Good |

Excellent |

Rear (physics) |

|

Traction Wet/Hills |

Adequate |

Superior |

Rear (weight distribution) |

|

Handling |

Front-heavy initially |

Natural balanced |

Rear (traditional feel) |

|

Drivetrain Compatibility |

Universal (any system) |

Derailleur/cassette needed |

Front (flexibility) |

|

Maximum Power |

500W practical |

4000W+ possible |

Rear (unlimited) |

|

Reversibility |

10-15 minutes |

25-30 minutes |

Front (easier) |

|

Cable Management |

More complex (steering) |

Simpler (no steering) |

Rear (easier) |

|

Component Cost |

Lower (no cassette tools) |

Moderate (tools included) |

Front (slight) |

|

Weight Distribution |

Front-heavy |

Balanced/natural |

Rear (physics) |

|

Best Applications |

Flat urban, legal compliance |

Hills, performance, all-around |

Application-dependent |

Kirbebike System Examples

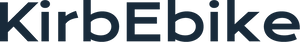

Front-Wheel Systems

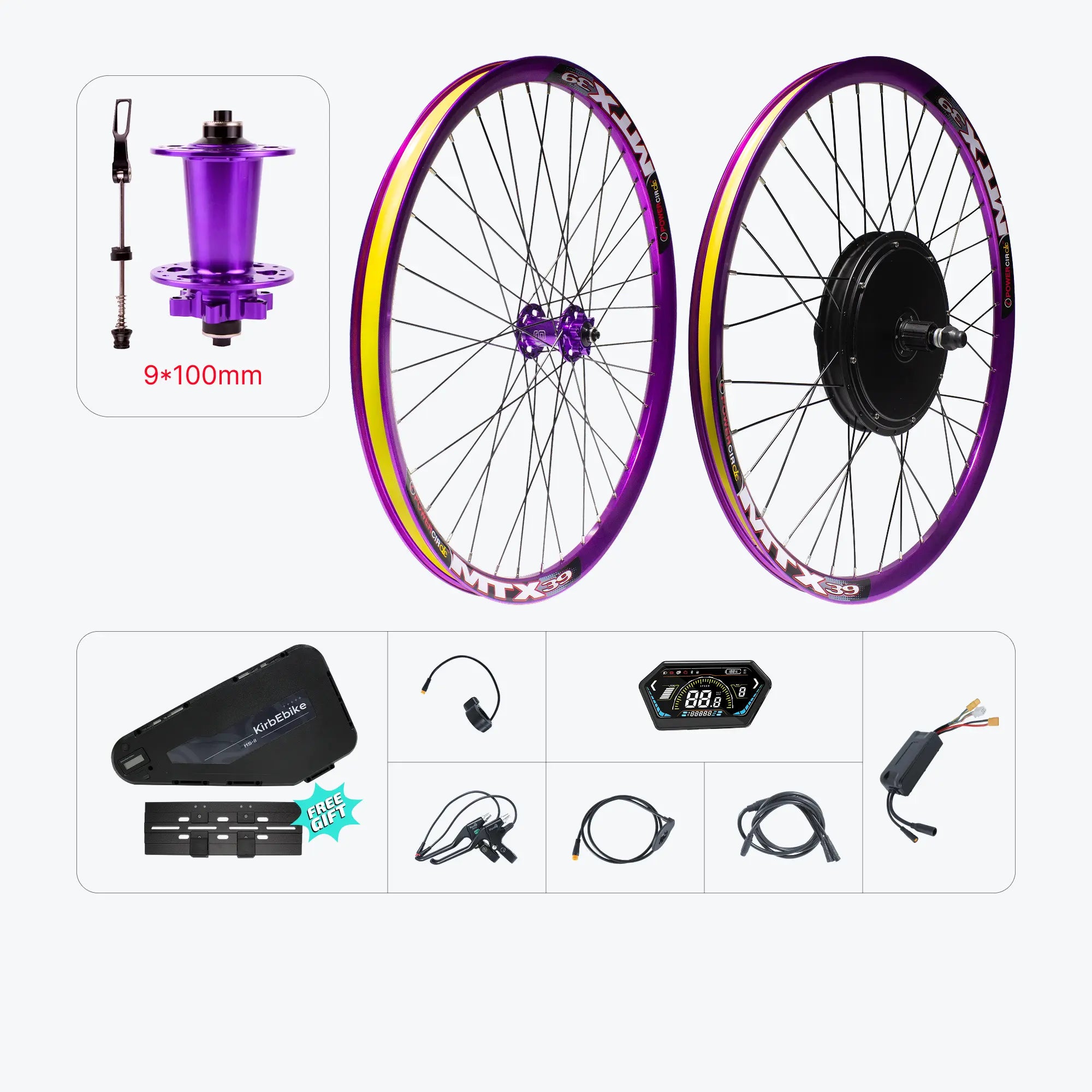

Rear-Wheel Systems

500-750W Rear Hub (Most Popular):

- Motor: 4.5kg SHENGYI geared

- Speed: 35-40 km/h

- Application: All-around use, most riders

- Advantages: Hills capable, versatile, proven

- Battery: 36V 13Ah to 48V 16Ah

48V 1000W Rear Hub:

- Motor: 4-6.2kg direct-drive

- Speed: 45-50 km/h

- Application: Performance, serious hills

- Torque arms: Recommended

- Battery: 48V 16-20Ah

52V 2000W+ Systems:

- Motor: 5.1-6.8kg heavy-duty

- Speed: 50-85+ km/h depending on power

- Application: Maximum performance

- Torque arms: Mandatory both sides

- Battery: 52V 20-30Ah or 60-72V options

Application-Based Selection

Choose Front-Wheel Motor When:

Priority: Simplicity and Flexibility

✓ First-time conversion (easiest success) ✓ Flat urban terrain (traction adequate) ✓ Legal compliance important (250W available) ✓ Internal hub gears (Shimano Alfine, Rohloff, etc.) ✓ Belt drive system (Gates Carbon Drive) ✓ Vintage/unusual bicycle (compatibility concerns) ✓ Rental/borrowed bike (reversibility valued) ✓ Minimal tools available (basic installation) ✓ Mechanical confidence low (simplicity essential) ✓ Gentle assistance adequate (not performance-focused)

Typical Rider: Urban commuter, 5-15km flat routes, legal compliance priority, first electric experience, values simplicity over performance, unusual drivetrain, mechanical novice, 250-500W adequate

Choose Rear-Wheel Motor When:

Priority: Performance and Capability

✓ Hills regular (superior traction essential) ✓ Wet conditions common (traction critical) ✓ Power over 500W desired (front inadequate) ✓ Natural handling valued (balanced dynamics) ✓ Performance focus (speed, capability) ✓ Heavy loads carried (cargo, touring) ✓ Off-road riding (loose surfaces, technical terrain) ✓ Serious cycling (not casual assistance) ✓ Mechanical comfort adequate (moderate installation) ✓ Long-term primary bike (not temporary)

Typical Rider: Performance-minded, 10-30km routes including hills, values capability, standard derailleur drivetrain, mechanically comfortable, 750-2000W power range, primary transportation, serious cycling investment

Real-World Performance

Front-Wheel Success: Urban Flat Commuter

System: 48V 250W Front Geared Hub

Rider Experience (15 Months):

- Installation: 25 minutes first-time (confidence building)

- Terrain: Flat urban, bike lanes

- Traction: Perfectly adequate dry conditions

- Rain: Cautious power application learned, manageable

- Handling: Front-heavy first week, adapted completely

- Performance: 30 km/h adequate, legal compliant

- Satisfaction: "Perfect for my needs—simplicity valued"

Key Insight: "Front-wheel perfect flat urban use—installation simplicity, universal compatibility, adequate performance made electric cycling accessible without intimidating complexity."

Rear-Wheel Success: Hilly Commuter

System: 48V 1000W Rear Direct-Drive

Key Insight: "Rear-wheel traction advantage non-negotiable hilly wet conditions—installation complexity worthwhile for superior daily performance and natural handling valued long-term."

Front-Wheel Challenge: Hilly Terrain

System: 48V 500W Front Geared Hub

Rider Experience (Abandoned After 6 Months):

- Installation: Easy (positive)

- Terrain: 10-12% hills regular (problematic)

- Traction: Front wheel spin wet hills (frustrating)

- Power application: Careful required (defeating purpose)

- Handling: Acceptable after adaptation

- Outcome: Sold, purchased rear-wheel 1000W system

- Satisfaction: "Front inadequate hills—should have chosen rear initially"

Key Lesson: Front-wheel traction limitations real hills and wet conditions—marketing suggesting "adequate" proved frustrating actual use, rear-wheel solved immediately.

Technical Insights

Why Rear Traction Wins Physics

Weight Transfer During Acceleration:

Basic physics explains rear-wheel superiority:

- Acceleration → inertia shifts weight rearward → front unweights, rear loads

- Climbing → gravity shifts weight rearward → front unweights, rear loads

- Combined → acceleration up hills = maximum rear loading, minimal front

- Front-wheel → fights weight transfer (loses traction precisely when needed most)

- Rear-wheel → benefits from weight transfer (gains traction when needed most)

Power Application Reality:

Attempting 750W+ front motor on 10% wet grade = almost certain front wheel slip. Same power rear wheel = confident traction. Not theory—consistent real-world experience.

Cable Management Differences

Front-Wheel Challenge:

Motor wheel must rotate for steering while cables remain stationary:

- Cables must loop allowing full steering rotation

- Zip-tie routing critical (prevent snagging)

- Testing full lock both directions essential

- Aesthetically challenging (visible cables handlebar area)

- Takes care but manageable

Rear-Wheel Simplicity:

Rear wheel doesn't steer:

- Cables route simply (down tube, chainstay)

- No rotation accommodation needed

- Cleaner aesthetic (cables away from visibility)

- Professional appearance easier

Decision Framework Summary

Choose Front-Wheel For: Flat terrain + simplicity priority + unusual drivetrain + first conversion + legal compliance + reversibility valued + mechanical novice + gentle assistance adequate = Front-wheel optimal choice

Choose Rear-Wheel For: Hills present + traction critical + performance priority + power over 500W + natural handling valued + standard drivetrain + mechanical comfort adequate + serious cycling = Rear-wheel optimal choice

Reality Check:

Most serious e-bike riders ultimately prefer rear-wheel placement for superior traction, natural handling, and unlimited power capability—but front-wheel serves specific needs (simplicity, unusual drivetrains, flat terrain) where advantages outweigh limitations making technology selection genuinely application-dependent rather than universally superior.

Making Your Choice

Understanding that neither configuration represents universally superior choice enables informed selection matching motor placement to your specific terrain conditions, performance requirements, mechanical comfort, and riding priorities. Explore the complete electric bike kit battery range including both front-wheel and rear-wheel systems with detailed specifications, application guidance, and expert support ensuring your conversion delivers optimal performance through appropriate motor placement matching your cycling reality.

Frequently Asked Questions

Is front or rear wheel better for e-bike conversion?

Depends entirely on application: front-wheel (250-500W) excels flat urban commuting through 20-minute installation, universal drivetrain compatibility, complete reversibility, and adequate performance where traction irrelevant—rear-wheel (250-4000W).

Why do front-wheel e-bike motors have traction problems?

Physics: acceleration and climbing shift weight rearward reducing front wheel loading exactly when motor demands maximum traction, creating wheel slip on hills, wet surfaces, and loose terrain especially above 500W.

Can I use front-wheel motor on hilly terrain?

Technically yes with limitations: 250-500W front motors manage gentle grades (5-8%) dry conditions carefully, but steep sustained hills (10%+), wet weather, or aggressive power application cause frequent front wheel slip frustration.

Is front-wheel e-bike conversion easier to install than rear-wheel?

Yes significantly: front installation 20 minutes (wheel replacement only, no drivetrain interaction), rear installation 25-30 minutes (cassette transfer, derailleur adjustment, potential torque arms).

Do I need torque arms for front or rear wheel motor?

Front-wheel: Optional 250-500W (low power, low torque), rarely used. Rear-wheel: Recommended 750W, one side mandatory 1000-1500W, two sides required 2000W+ (high torque risks dropout failure without reinforcement).