The fundamental choice between mid-drive and hub motor technology represents the single most consequential decision in e-bike conversion, creating profound differences in efficiency, climbing capability, maintenance requirements, installation complexity, and total ownership costs that make one technology dramatically superior for specific applications while creating significant disadvantages for others.

Understanding which best ebike kit motor type serves your particular cycling needs requires moving beyond marketing generalizations about "better" or "worse" toward honest assessment of how each technology performs across varied terrain, usage patterns, mechanical capabilities, and budget realities—because neither represents universally optimal choice despite strong opinions on both sides of this contentious debate.

Understanding the Core Difference

Where Motors Mount Determines Everything:

- Hub motors mount inside wheel hub, driving bicycle directly through wheel rotation

- Mid-drive motors mount at bottom bracket, driving bicycle through chain and gears

This fundamental architectural difference creates cascading effects across every performance characteristic, maintenance requirement, and practical consideration—understanding why motor placement matters so profoundly enables informed decisions rather than assumptions based on incomplete information.

Hub Motor Technology Deep Dive

How Hub Motors Work

Direct Wheel Drive:

Hub motors contain the motor within the wheel itself:

Operating Principle:

- Motor housed inside hub shell

- Stator mounts to axle (stationary)

- Rotor connects to wheel (rotates)

- Magnetic fields create rotation

- Wheel spins directly (no intermediate components)

- Power transfers immediately to ground

Two Hub Motor Types:

- Geared Hub Motors (250-750W): Internal planetary gears, lightweight (2.7-4.5kg), excellent low-speed torque

- Direct-Drive Hub Motors (1000-4000W): No internal gears, heavier (5-8kg), superior high-speed efficiency

Hub Motor Advantages

Installation Simplicity:

Wheel replacement takes 20-25 minutes:

✓ Front wheel: Remove, install motor wheel, connect cables (20 minutes) ✓ Rear wheel: Transfer cassette, install motor wheel, adjust derailleur (25-30 minutes) ✓ No bottom bracket removal (major simplification) ✓ No crank extraction (specialized tools unnecessary) ✓ Basic mechanical skills adequate

No Drivetrain Wear Increase:

Hub motors bypass chain and gears entirely:

✓ Chain life normal (3000-5000km typical) ✓ Cassette lasts normally (3-4 chains) ✓ Chainring wear standard ✓ No motor torque through drivetrain ✓ Maintenance costs minimal

Unlimited Power Potential:

Direct drive enables extreme capability:

✓ 250W: Legal compliance available ✓ 500-1000W: All-around performance ✓ 1500-2000W: Serious capability ✓ 2500-4000W: Extreme power (private property) ✓ No inherent power ceiling

Proven Reliability:

Simple construction means durability:

✓ Minimal wearing parts (geared hubs: eventual gear wear) ✓ Direct-drive: Essentially maintenance-free ✓ Weather sealed (IP65-IP66) ✓ Decades lifespan possible (direct-drive) ✓ Consistent performance

Hub Motor Disadvantages

Efficiency Limitations:

Hub motors operate at fixed gear ratio:

Weight Distribution:

Motor weight concentrated at wheel:

- Unsprung weight: 2.7-8kg added to wheel

- Handling impact: Noticeable initially

- Suspension performance: Affected (MTB applications)

- Wheel strength: Critical (spoke tension)

No Regenerative Braking (Geared):

Geared hub motors freewheel:

- Coasting unpowered: Advantage for pedaling

- Energy recovery: Impossible (freewheeling mechanism)

- Direct-drive only: Regenerative braking possible

Mid-Drive Technology Deep Dive

How Mid-Drive Motors Work

Powering Through Gears:

Mid-drive motors mount at bottom bracket:

Natural Bicycle Feel:

Centered weight preserves handling:

✓ Motor weight: 4.8kg positioned low and central ✓ Unsprung weight: Minimal (wheels unweighted) ✓ Suspension performance: Preserved (MTB critical) ✓ Weight distribution: Balanced natural ✓ Handling characteristics: Professional bicycle dynamics

Torque Sensor Integration:

Quality mid-drives feature responsive power delivery:

- Tongsheng TSDZ8: Integrated torque sensor

- Instant response: Power matches pedal pressure

- Proportional assistance: Harder pedaling = more motor power

- Natural feel: Indistinguishable from strong human power

- Rider control: You determine assistance level

Mid-Drive Disadvantages

Accelerated Drivetrain Wear:

Motor torque exceeds human power:

The Hidden Cost:

- Chain replacement: Every 1500-3000km (vs 3000-5000km non-electric)

- Cassette life: 2-3 chains (vs 3-4 chains)

- Chainring wear: Monitor regularly

- Annual costs: £70-100 typical (moderate usage)

- Ongoing expense: Unavoidable design consequence

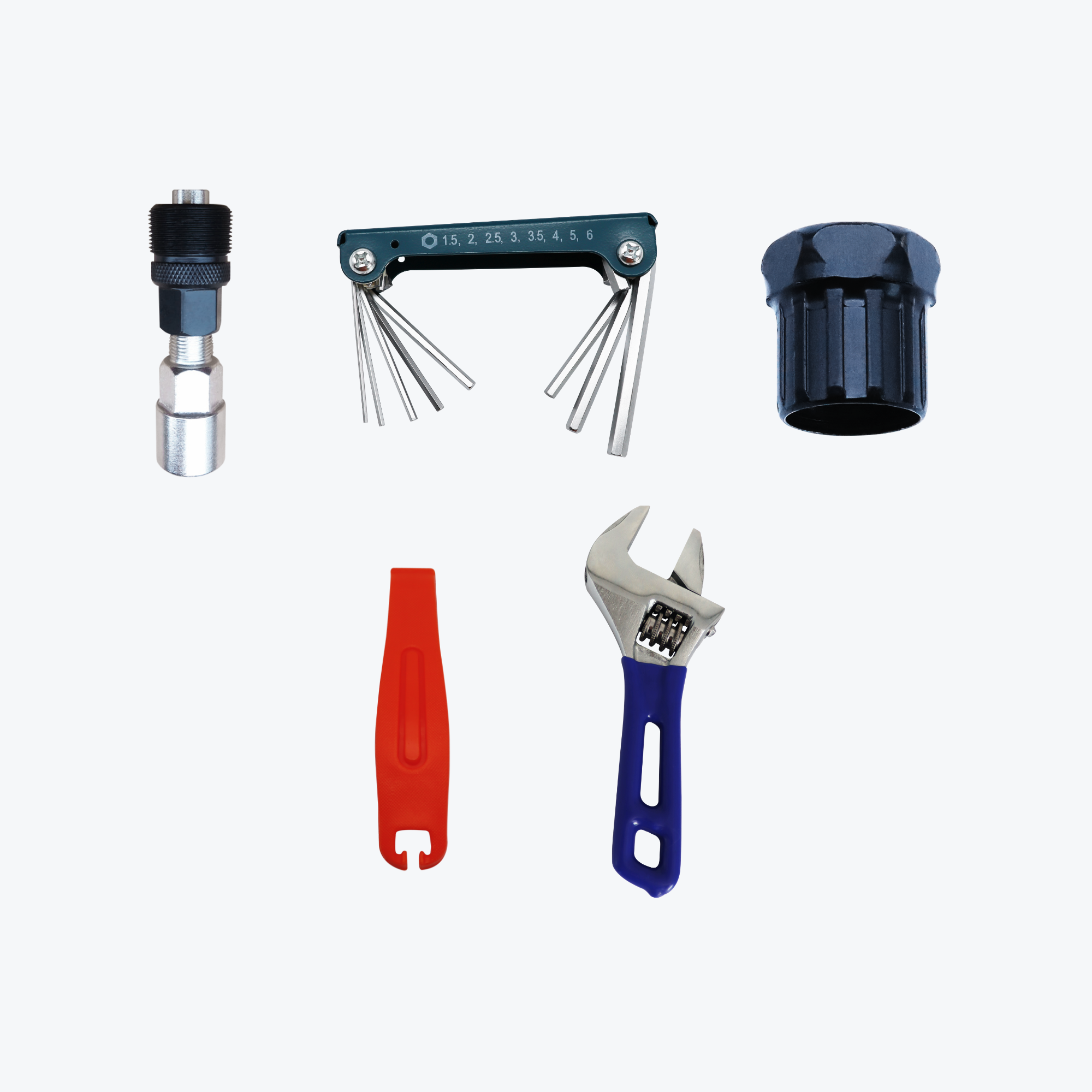

Installation Complexity:

Drivetrain becomes limiting factor:

- Practical maximum: 750W sustained

- Beyond 750W: Chain/cassette durability concerns

- High power needs: Hub motors better choice

- Design limitation: Physics constraint

Frame Compatibility:

Not all bicycles accept mid-drives:

- Bottom bracket type: Threaded 68mm or 73mm required

- Press-fit BB: Incompatible

- Chainstay clearance: Motor body must fit

- Frame material: Carbon fiber risky

- Suspension design: Pivot clearance critical

Comprehensive Performance Comparison

|

Factor |

Hub Motor |

Mid-Drive Motor |

Winner |

|

Installation Time |

20-30 minutes |

30-40 minutes |

Hub (simpler) |

|

Mechanical Skill |

Basic |

Moderate |

Hub (easier) |

|

Flat Terrain Efficiency |

Good |

Good |

Tie |

|

Hill Climbing Efficiency |

Moderate (requires high power) |

Excellent (gear advantage) |

Mid-Drive (clear) |

|

Weight Distribution |

Wheel-mounted (4-8kg) |

Centered (4.8kg) |

Mid-Drive (balanced) |

|

Drivetrain Wear |

Normal (no increase) |

50-100% faster |

Hub (lower costs) |

|

Maximum Power |

4000W+ possible |

750W practical limit |

Hub (unlimited) |

|

Maintenance Costs |

Minimal |

£70-100+ annually |

Hub (lower) |

|

Natural Feel |

Adequate |

Superior (torque sensor) |

Mid-Drive |

|

Battery Efficiency |

Good |

Excellent (20-30% better) |

Mid-Drive |

|

Suspension Performance |

Impacted (unsprung weight) |

Preserved |

Mid-Drive |

|

Compatibility |

Universal (any drivetrain) |

Threaded BB only |

Hub (flexible) |

|

Long-Term Reliability |

Excellent |

Good (drivetrain wear) |

Hub |

|

Best Applications |

Flat/moderate terrain, power priority |

Hills, efficiency, natural feel |

Application-dependent |

Real-World Performance Stories

Hub Motor Success: Flat Urban Commuter

System: 48V 1000W Rear Hub Direct-Drive

Rider Profile:

- 20km flat urban commute daily

- Speed priority (faster arrival)

- Mechanical novice

- Budget-conscious long-term

18-Month Results:

✓ Installation: 25 minutes (manageable first-time) ✓ Performance: 45-50 km/h comfortable cruising ✓ Efficiency: Adequate flat terrain ✓ Maintenance: Zero drivetrain cost increase ✓ Reliability: Completely trouble-free ✓ Total ownership cost: Initial investment only ✓ Satisfaction: "Perfect for my flat commute—no maintenance, adequate power, simple installation."

Key Insight: Flat terrain negates mid-drive efficiency advantage while hub motor simplicity, zero maintenance increase, and adequate performance create optimal value proposition for this application.

Mid-Drive Success: Hilly Mountain Biker

System: 48V 750W Tongsheng TSDZ8 Mid-Drive

Rider Profile:

- Technical trail riding regular

- 12-18% sustained grades common

- Natural feel valued

- Mechanically comfortable

18-Month Results:

✓ Installation: 35 minutes with video guidance ✓ Climbing: 15-18% grades conquered efficiently (transformative) ✓ Efficiency: 40-50km range aggressive trail riding ✓ Feel: Natural responsive (torque sensor excellence) ✓ Maintenance: 2 chains replaced (£40), expected cost ✓ Suspension: Performance preserved (centered weight) ✓ Satisfaction: "Gear advantage game-changing hills—maintenance accepted for superior climbing efficiency"

Key Insight: Steep grades make mid-drive gear leverage advantage non-negotiable—20-30% efficiency gain justifies accelerated drivetrain wear and installation complexity for hill-focused applications.

Hub Motor Limitation: Steep Hills

System: 48V 750W Rear Hub Geared

Rider Experience (Switched After 8 Months):

✗ Installation: Easy (positive) ✗ Flat performance: Excellent (positive) ✗ Hill climbing: Struggled 12-15% grades (frustrating) ✗ Battery drain: Rapid on inclines (excessive consumption) ✗ Solution: Sold, purchased TSDZ8 mid-drive ✗ Outcome: Immediate hill climbing transformation

Key Lesson: Hub motors adequate gentle grades but struggle sustained steep climbs where mid-drive gear advantage creates dramatic efficiency and capability differences—terrain dictates optimal technology.

Application-Based Selection Guide

Choose Hub Motor When:

Terrain and Priorities Favor Simplicity:

✓ Flat to gentle terrain predominates (under 8% grades typical) ✓ Speed priority over climbing efficiency ✓ Mechanical simplicity valued (basic installation skills) ✓ Minimal maintenance desired (avoid ongoing drivetrain costs) ✓ Maximum power wanted (1500-4000W capability) ✓ Budget-conscious long-term (lower total ownership cost) ✓ Any drivetrain type (internal hubs, belt drive, unusual systems) ✓ Quick installation critical (20-30 minutes)

Typical Hub Motor Rider: Urban commuter, 10-30km flat routes, speed-focused, mechanical novice, budget-conscious, values simplicity and reliability over absolute efficiency, power over 750W desired

Choose Mid-Drive When:

Terrain and Priorities Demand Efficiency:

✓ Hills regular feature (10%+ sustained grades common) ✓ Maximum efficiency priority (extend range, reduce battery size) ✓ Natural bicycle feel valued (torque sensor response) ✓ MTB/trail riding (suspension performance preserved) ✓ Weight distribution critical (handling importance) ✓ Mechanically comfortable (moderate installation skills) ✓ Drivetrain wear accepted (ongoing maintenance budgeted) ✓ 500-750W adequate (gear leverage multiplies power)

Typical Mid-Drive Rider: Mountain biker, hilly commuter, 10-40km varied terrain, efficiency-focused, mechanically competent, values natural feel and climbing capability, accepts maintenance costs for superior hill performance

Total Cost of Ownership Analysis

Hub Motor (5 Years, 10,000km):

Initial Investment: Conversion kit + battery Ongoing Costs:

- Chain replacement: 2-3 chains (normal wear) = £40-60

- Cassette: 1 replacement = £30-40

- Total 5-Year: Initial + £70-100 drivetrain

Mid-Drive (5 Years, 10,000km):

Initial Investment: Conversion kit + battery (similar hub motor) Ongoing Costs:

- Chain replacement: 5-6 chains (accelerated) = £100-150

- Cassette: 2 replacements = £60-80

- Chainring: 1 replacement possible = £30-40

- Total 5-Year: Initial + £190-270 drivetrain

Cost Difference: £120-170 over 5 years favoring hub motor

However: Mid-drive 20-30% efficiency advantage potentially enables smaller battery (£100-150 savings) offsetting some maintenance costs for efficiency-focused applications.

Making Your Decision

Quick Decision Framework:

Answer These Questions:

- Terrain: Primarily flat/gentle (under 8%) or hilly (10%+)?

- Flat → Hub motor advantage

- Hilly → Mid-drive advantage

- Mechanical Comfort: Basic or moderate skills?

- Basic → Hub motor easier

- Moderate → Mid-drive manageable

- Maintenance Tolerance: Ongoing costs acceptable?

- Minimize → Hub motor

- Accepted → Mid-drive option

- Power Needs: Under 750W or higher?

- Under 750W → Either works

- 1000W+ → Hub motor only

- Priority: Simplicity/power or efficiency/feel?

- Simplicity → Hub motor

- Efficiency → Mid-drive

The Honest Answer:

Neither technology universally superior—hub motors excel flat terrain, simplicity priorities, power over 750W, and minimal maintenance through direct drive bypassing drivetrain, while mid-drives dominate hilly terrain, efficiency focus, natural feel priorities, and MTB applications through gear leverage enabling smaller lighter motors achieving superior climbing via mechanical advantage rather than brute electrical force.

Ready to transform your cycling with appropriate motor technology? Explore the complete electric bike kit battery range including both hub motor systems (250W-4000W capability, minimal maintenance, simple installation) and the mid motor electric conversion kit Tongsheng TSDZ8 (500-750W, torque sensor, superior efficiency) with detailed specifications, honest performance expectations, and expert support ensuring your conversion matches motor technology to terrain realities delivering optimal satisfaction through informed selection.

Frequently Asked Questions

Is mid-drive better than hub motor for e-bike conversion?

Neither universally better—mid-drive excels hilly terrain through gear leverage enabling 500W matching 1500W hub motor climbing efficiency while delivering 20-30% better battery usage, natural torque-sensor feel, and preserved suspension (MTB).

Why do mid-drive motors climb hills better than hub motors?

Gear leverage multiplication: mid-drive powers through bicycle's existing gears enabling low gear to multiply 500W motor output into 1500W+ effective wheel torque while maintaining optimal motor RPM (efficient operation).

Do mid-drive motors wear out chains and cassettes faster?

Yes significantly—motor torque (140Nm TSDZ8) exceeds human power (70-90Nm typical) accelerating drivetrain wear 50-100%: chains need replacement every 1500-3000km versus 3000-5000km non-electric.

Which is easier to install: hub motor or mid-drive conversion kit?

Hub motor significantly easier: front wheel 20 minutes (wheel replacement only), rear wheel 25-30 minutes (cassette transfer, derailleur adjustment), basic mechanical skills adequate. Mid-drive 30-40 minutes requiring bottom bracket removal.

Can hub motors handle steep hills?

Adequately with sufficient power but inefficiently: 750W hub motor manages 8-10% grades adequately, 1000-1500W handles 10-15% grades, 2000W+ conquers any grade through brute force—but operates inefficiently (motor below optimal RPM) consuming battery rapidly.