Mid-drive motors mount at the bicycle's bottom bracket, powering the bike through the existing chain and gears rather than directly driving a wheel. This fundamental architectural difference from hub motors creates distinct performance characteristics, efficiency advantages, handling dynamics, and maintenance considerations that make mid-drive systems ideal for specific applications while less suitable for others.

Understanding when the best ebike kit choice involves mid-drive technology versus hub motor alternatives requires examining real-world performance across various riding conditions, maintenance implications, cost factors, and honest assessment of your specific cycling needs rather than assumptions about which technology represents universally superior solutions.

Why Mid-Drive Motors Excel

The Gear Leverage Advantage

Power Multiplication Through Gears:

Mid-drive systems leverage your bicycle's existing gear system, creating dramatic efficiency advantages impossible for hub motors:

How Gear Leverage Works:

- Motor outputs 500W to chainring

- Low gear multiplies torque 3-4x

- Effective wheel power exceeds 1500W

- Steep grades conquered efficiently

- Battery range extended significantly

Practical Impact:

A 500W mid-drive system in low gear delivers equivalent climbing power to a 1500W-2000W hub motor—this isn't marketing hyperbole but fundamental physics enabling smaller, lighter, more efficient motors achieving superior hill-climbing through mechanical advantage rather than brute electrical force.

Real-World Climbing:

- 36V 500W mid-drive: Handles 12-15% grades confidently

- 48V 750W mid-drive: Conquers 15-20% sustained climbs

- Efficiency: 20-30% better than equivalent hub motor

- Range: 40-60km typical (extended through efficiency)

Natural Pedaling Feel

Torque Sensor Integration:

Quality mid-drive systems like the Tongsheng TSDZ8 feature integrated torque sensors creating responsive natural assistance:

- Immediate Response: Assistance begins instantly with pedal pressure

- Proportional Power: Motor output matches your effort level

- Smooth Delivery: No on/off jerking sensation

- Cycling Feel: Mimics natural strong cyclist experience

- Rider Control: You determine assistance through pedaling

Weight Distribution Benefits

Centered Mass Advantage:

Mid-drive motors mount at the bicycle's center of gravity:

Handling Characteristics:

- Motor weight (4.8kg TSDZ8) positioned low and central

- Suspension performance preserved (unsprung weight minimal)

- Cornering balance natural (no wheel-mounted mass)

- Technical maneuvering enhanced

- Professional bicycle feel maintained

Comparison:

- Hub motor: 4-7kg unsprung weight at wheel (affects handling)

- Mid-drive: 4.8kg centered mass (optimal distribution)

- Rider perception: Mid-drive feels more like "normal" bicycle

Mid-Drive Disadvantages Honestly Assessed

Increased Drivetrain Wear

The Hidden Cost Nobody Discusses:

Mid-drive systems stress chains, cassettes, and chainrings beyond normal cycling loads—this represents the most significant ongoing expense that conversion guides rarely emphasize adequately:

Accelerated Component Replacement:

- Chain: Replace at 0.5-0.75% stretch vs 0.75-1.0% non-electric

- Chain Life: 1500-3000km vs 3000-5000km non-electric (50-100% faster wear)

- Cassette: Lasts 2-3 chains vs 3-4 chains non-electric

- Chainring: Monitor wear, replace when needed

- Annual Costs: Can exceed £100-150 depending on usage

Why This Occurs: Motor torque (140Nm TSDZ8) dramatically exceeds human pedaling force (typically 70-90Nm peak), accelerating wear on drivetrain components designed for human power levels, not sustained motor torque through thousands of kilometers.

Installation Complexity

Bottom Bracket Replacement Required:

Mid-drive installation demands more mechanical expertise than hub motor conversions:

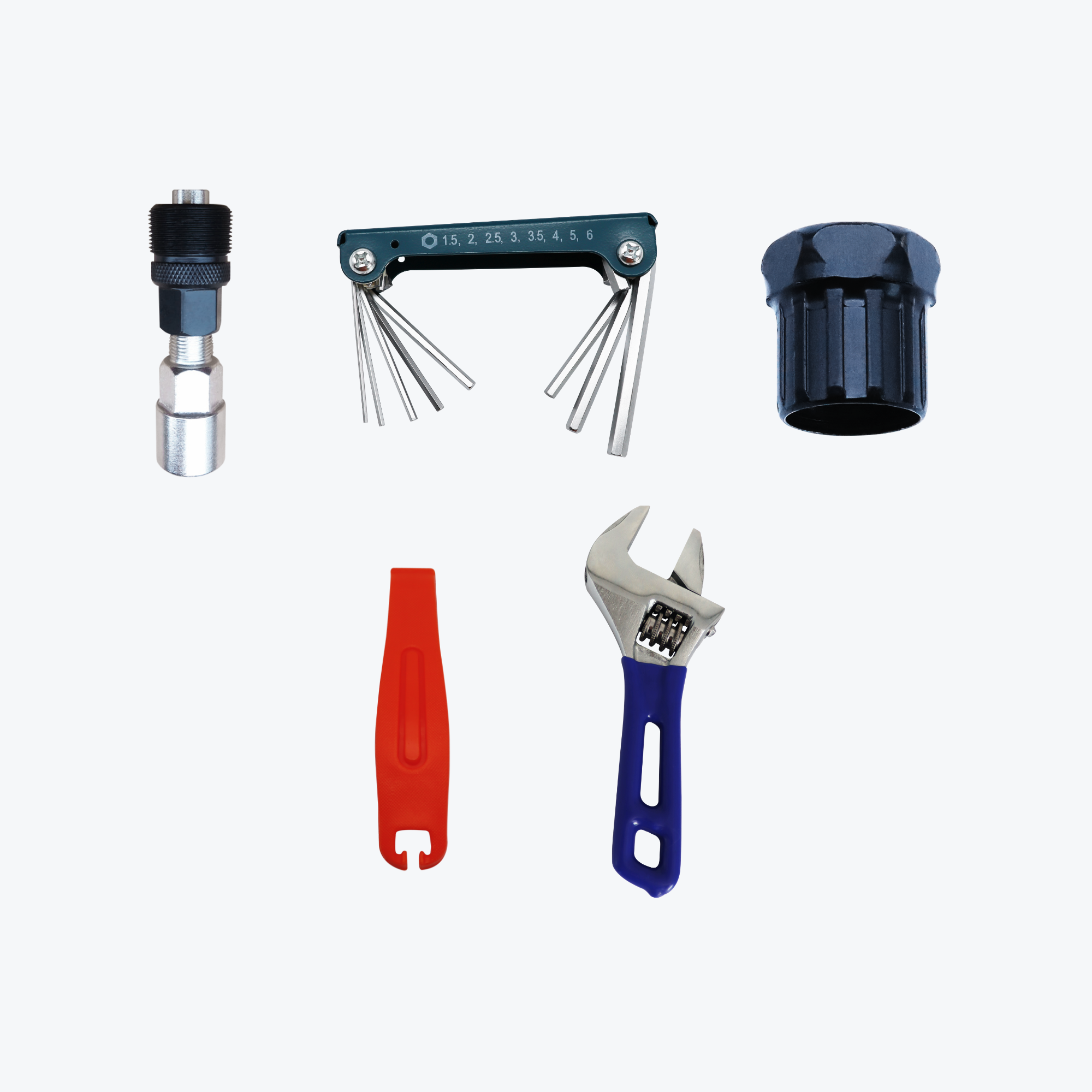

Installation Process:

- Remove cranks (crank puller tool needed)

- Extract bottom bracket (special tools required)

- Install mid-drive motor (precise alignment critical)

- Attach cranks to motor (proper torque essential)

- Route cables carefully (clean installation)

- Program controller (technical knowledge helpful)

Time Investment: 30-40 minutes experienced installer vs 20-25 minutes hub motor

Skill Level: Moderate mechanical comfort required vs basic competence hub motor

Chain Line and Compatibility Concerns

Frame Compatibility Critical:

Not all bicycles accept mid-drive conversions equally:

Compatibility Factors:

- Bottom Bracket Type: 68mm or 73mm width standard (verify yours)

- Chainstay Clearance: Motor body must clear frame (some compact frames incompatible)

- Chain Length: Typically requires longer chain

- Frame Material: Steel/aluminum excellent, carbon fiber risky

- Suspension Frames: Additional considerations (pivot clearance, cable routing)

The Tongsheng TSDZ8: Mid-Drive Benchmark

System Specifications

Complete Technical Overview:

|

Specification |

36V 500W Version |

48V 750W Version |

|

Rated Power |

500W |

750W |

|

Maximum Torque |

140Nm |

140Nm |

|

Motor Weight |

4.8kg |

4.8kg |

|

Speed Range |

30-40 km/h |

35-50 km/h |

|

Battery |

36V 16Ah LG cells |

48V 16Ah LG cells |

|

Range |

40-50km |

50-60km |

|

Sensor |

Integrated torque sensor |

Integrated torque sensor |

|

Efficiency |

85-90% |

85-90% |

|

Climbing |

12-15% grades |

15-20% grades |

Why TSDZ8 Stands Out

Torque Sensor Advantage:

Unlike cheaper cadence-sensor-only mid-drives, the TSDZ8's integrated torque sensor provides:

- Instant power delivery matching pedal pressure

- Proportional assistance (harder pedaling = more motor power)

- Natural cycling feel indistinguishable from strong human power

- Smooth power modulation through all conditions

- Professional e-bike experience

Quality Construction:

- Sealed bearings (weather resistance, longevity)

- Robust aluminum housing (durability, heat dissipation)

- Integrated design (reliability, reduced failure points)

- Professional-grade components (LG battery cells, proven motor technology)

When to Choose Mid-Drive

Ideal Applications

Scenario 1: Mountain Biking and Technical Trails

Mid-drive technology excels off-road:

✓ Gear leverage conquers steep technical climbs (15-20%+ grades) ✓ Low-speed torque exceptional (technical maneuvering) ✓ Weight distribution preserves suspension performance ✓ Natural power delivery enhances control ✓ Efficiency maximizes range challenging terrain

Scenario 2: Serious Hill Climbing

Daily commutes involving sustained steep grades:

✓ 500-750W mid-drive outperforms 1500W hub motor efficiency ✓ Battery range extended 20-30% through gear leverage ✓ Smooth consistent power steep climbs ✓ Motor operates efficiently (optimal RPM maintained through gearing) ✓ Investment justified by superior capability

Scenario 3: Performance and Efficiency Priority

Riders valuing natural feel, maximum range, professional dynamics:

✓ Torque sensor provides responsive natural assistance ✓ Gear leverage maximizes battery efficiency ✓ Centered weight maintains bicycle handling ✓ Long-distance touring capability ✓ Professional e-bike experience

When Hub Motors Serve Better

Situations Favoring Hub Technology

Scenario 1: Flat to Gentle Terrain

Urban commuting without significant hills:

- Hub motor adequate power delivery (no gear advantage needed)

- Simpler installation (20 minutes vs 30-40 minutes)

- No drivetrain wear increase (chains last normally)

- Lower maintenance (no specialized component wear)

- Comparable performance (flat terrain negates mid-drive efficiency advantage)

Scenario 2: Budget and Maintenance Considerations

Cost-conscious riders avoiding ongoing expenses:

- Hub motor: No accelerated drivetrain wear

- Mid-drive: Chain every 1500-3000km (added expense)

- Hub motor: Minimal ongoing maintenance

- Mid-drive: Regular drivetrain component replacement

- Five-Year Cost: Hub motor lower total ownership cost moderate terrain

Scenario 3: Maximum Power Priority

Raw power over efficiency:

- Hub motors: 2000-4000W systems available

- Mid-drive: Practical limit 750W (higher power damages drivetrain)

- Hub motors: Direct power delivery (no chain stress concerns)

- Mid-drive: Drivetrain becomes limiting factor high power

Mid-Drive vs Hub Motor Decision Matrix

|

Priority |

Choose Mid-Drive |

Choose Hub Motor |

|

Steep Hills Regular |

✓ Yes (gear advantage) |

Maybe (requires higher power) |

|

Flat Terrain Primary |

No (advantage wasted) |

✓ Yes (adequate) |

|

Efficiency Priority |

✓ Yes (20-30% better) |

No |

|

Natural Feel Valued |

✓ Yes (torque sensor) |

No |

|

Maintenance Tolerance |

Required (drivetrain wear) |

✓ Minimal |

|

Installation Simplicity |

No (30-40 minutes) |

✓ Yes (20 minutes) |

|

Budget Conscious |

No (higher total cost) |

✓ Yes |

|

Maximum Power Wanted |

No (750W practical limit) |

✓ Yes (4000W available) |

Installation Insights

What Makes Mid-Drive Installation Different

Bottom Bracket Considerations:

The mid motor electric conversion kit installation requires understanding bottom bracket standards:

Common Standards:

- 68mm English Thread: Most common standard bicycles

- 73mm English Thread: Mountain bikes typically

- Press-Fit: Not compatible (threaded required)

- Italian Thread: Rare (different threading direction)

Critical Steps:

- Crank Removal: Requires crank puller tool (included in kit)

- Bottom Bracket Extraction: Specialized tool needed (included)

- Motor Installation: Thread carefully (proper torque 35-40Nm)

- Chain Length: Typically need 2-4 additional links

- Cable Routing: Plan for clean professional appearance

Common Installation Challenges

Challenge 1: Seized Bottom Brackets

Old bicycles may have corroded bottom brackets:

- Solution: Penetrating oil, patience, proper leverage

- Prevention: Not applicable (existing condition)

- Professional Help: Consider if severely stuck

Challenge 2: Chain Length Determination

Calculating correct chain length:

- Method: Largest rear cog + largest front chainring + 2 links

- Testing: Verify all gear combinations work

- Adjustment: Add/remove links as needed

Real-World Performance

Mountain Bike Conversion Success

Rider Experience (18 Months):

Experienced MTB rider converted trail bike with 48V 750W TSDZ8:

Performance Results:

- Technical climbs conquered (15-18% sustained grades)

- Natural power delivery enhanced control

- Battery efficiency exceptional (40-50km aggressive trail riding)

- Weight distribution preserved suspension performance

- Handling remained professional-grade

Maintenance Reality:

- Chain replaced every 2500km (accelerated wear accepted)

- Cassette replaced after 3 chains (expected)

- Total maintenance costs: £120 annually (drivetrain)

- Motor: Zero issues (completely reliable)

Satisfaction Assessment: "Mid-drive gear advantage transformative for technical climbing—would absolutely choose mid-drive again despite higher maintenance for this application."

Commuter Hub Motor Comparison

Same Rider's Urban Bike:

Flat urban commuter with 48V 1000W rear hub motor:

Performance:

- Adequate power flat terrain

- 20-minute installation

- Zero drivetrain wear increase

- Minimal maintenance

- Lower total ownership cost

Conclusion: "Right motor for application—hub motor serves flat commuting perfectly while mid-drive excels technical trails. Application determines optimal technology, not theoretical superiority."

Maintenance Planning

Expected Component Lifespan

Mid-Drive System:

- Chain: 1500-3000km (vs 3000-5000km non-electric)

- Cassette: 2-3 chains (vs 3-4 chains non-electric)

- Chainring: 7500-10000km typical

- Motor: Essentially maintenance-free (sealed construction)

Annual Maintenance Budget:

Moderate usage (5000km annually):

- Chains: 2 replacements = £40-60

- Cassette: 0.5 replacement = £30-40 (every 2 years)

- Total: £70-100 annually drivetrain wear

Preventive Maintenance

Extending Component Life:

✓ Chain lubrication after wet rides (essential) ✓ Clean drivetrain regularly (prevents accelerated wear) ✓ Check chain stretch frequently (0.75% replacement point) ✓ Use quality chains (economy chains wear faster) ✓ Smooth power application (avoid full-throttle starts) ✓ Appropriate gear selection (don't labor motor low gears)

Making Your Decision

Mid-drive e-bike conversion through systems like the Tongsheng TSDZ8 delivers exceptional efficiency (20-30% better than hub motors), natural torque-sensor-assisted power delivery, gear-leveraged climbing capability conquering 15-20% grades with 750W, and professional bicycle handling through centered weight distribution—but demands acceptance of accelerated drivetrain wear (chains every 1500-3000km).

For riders facing regular steep climbs, technical trail riding, or valuing maximum efficiency and natural feel, explore the complete electric bike kit battery range including the Tongsheng TSDZ8 mid-drive system delivering professional-grade performance, integrated torque sensing, and gear-leveraged power multiplication justifying higher maintenance through superior capability for demanding applications where mid-drive advantages outweigh hub motor simplicity and lower operating costs.

Frequently Asked Questions

Is mid-drive better than hub motor for e-bike conversion?

Depends on application: mid-drive excels steep climbing (gear leverage provides 2-3x efficiency advantage), technical trails.

How much does mid-drive increase chain and cassette wear?

Significantly—expect 50-100% faster wear: chains need replacement every 1500-3000km versus 3000-5000km non-electric, cassettes last 2-3 chains versus 3-4 chains, creating £70-100 annual maintenance costs moderate usagee.

What makes Tongsheng TSDZ8 mid-drive system special?

Integrated torque sensor (not just cadence) provides instant proportional power delivery matching pedal pressure creating natural responsive feel indistinguishable from strong human power.

Can any bike be converted to mid-drive motor?

Most threaded bottom bracket bikes work (68mm or 73mm English standard), but press-fit bottom brackets incompatible, carbon fiber frames risky, and some compact frames lack motor body clearances.

Is mid-drive conversion harder to install than hub motor?

Yes—mid-drive requires bottom bracket removal (specialized tools), crank extraction, motor threading, chain length calculation, and cable routing taking 30-40 minutes versus hub motor wheel replacement (20-25 minutes).