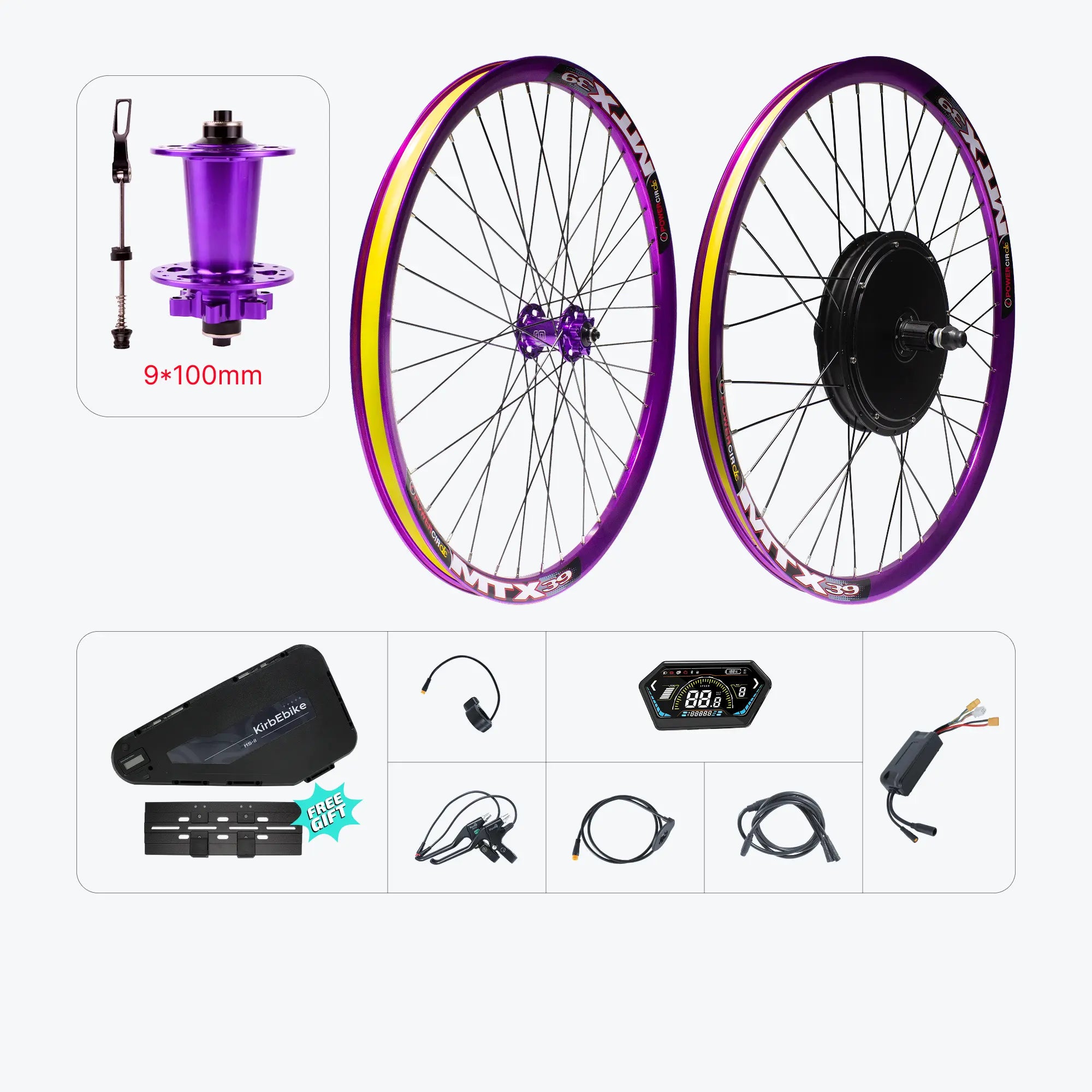

Installing a high power ebike conversion kit transforms your bicycle into a thrilling electric machine, but standard bicycle components often can't safely handle the increased speeds, weight, and forces these systems generate.

While the motor and battery provide the power, your brakes and wheels determine whether you can control and safely enjoy that performance. Understanding which upgrades are essential versus optional helps you build a conversion that's both exhilarating and safe.

Why Standard Components Fail Under High Power

Traditional bicycles are engineered for human-powered speeds of 15-30 km/h. High-power conversion kits—particularly systems above 1500W—routinely reach 50-85 km/h, creating forces that overwhelm components designed for much gentler duty.

The Physics of High-Power Stress

Kinetic Energy Increases Exponentially: Doubling speed quadruples the kinetic energy your brakes must dissipate. A 75kg rider plus 20kg bike traveling at 50 km/h carries four times the energy of the same system at 25 km/h.

Acceleration Forces Strain Wheels: A 2000W motor can accelerate from standstill to 40 km/h in under 5 seconds. This rapid acceleration creates enormous torque that standard wheels weren't built to handle, leading to spoke failures and rim deformation.

Sustained High-Speed Operation: Electric assistance enables sustained high speeds that manual pedaling rarely achieves. This continuous high-speed operation generates heat in brakes and stress in wheels that exceeds design parameters.

Brake System Requirements by Power Level

Different power levels demand different brake capabilities. Matching brake specifications to your motor power ensures adequate stopping performance.

Minimum Brake Standards for High-Power Systems

|

Motor Power |

Minimum Rotor Size |

Brake Type |

Pad Material |

Expected Stopping Distance (40 km/h) |

|

1000W-1500W |

160mm front/rear |

Hydraulic disc |

Semi-metallic |

8-10 meters |

|

1500W-2000W |

180mm front, 160mm rear |

Hydraulic disc |

Sintered metal |

8-10 meters |

|

2000W-3000W |

180mm front/rear |

Hydraulic disc |

Sintered metal |

10-12 meters |

|

3000W-4000W |

203mm front, 180mm rear |

4-piston hydraulic |

Sintered metal |

10-12 meters |

These specifications represent minimum standards. Riders frequently descending steep terrain or carrying cargo should upgrade one level beyond their power rating.

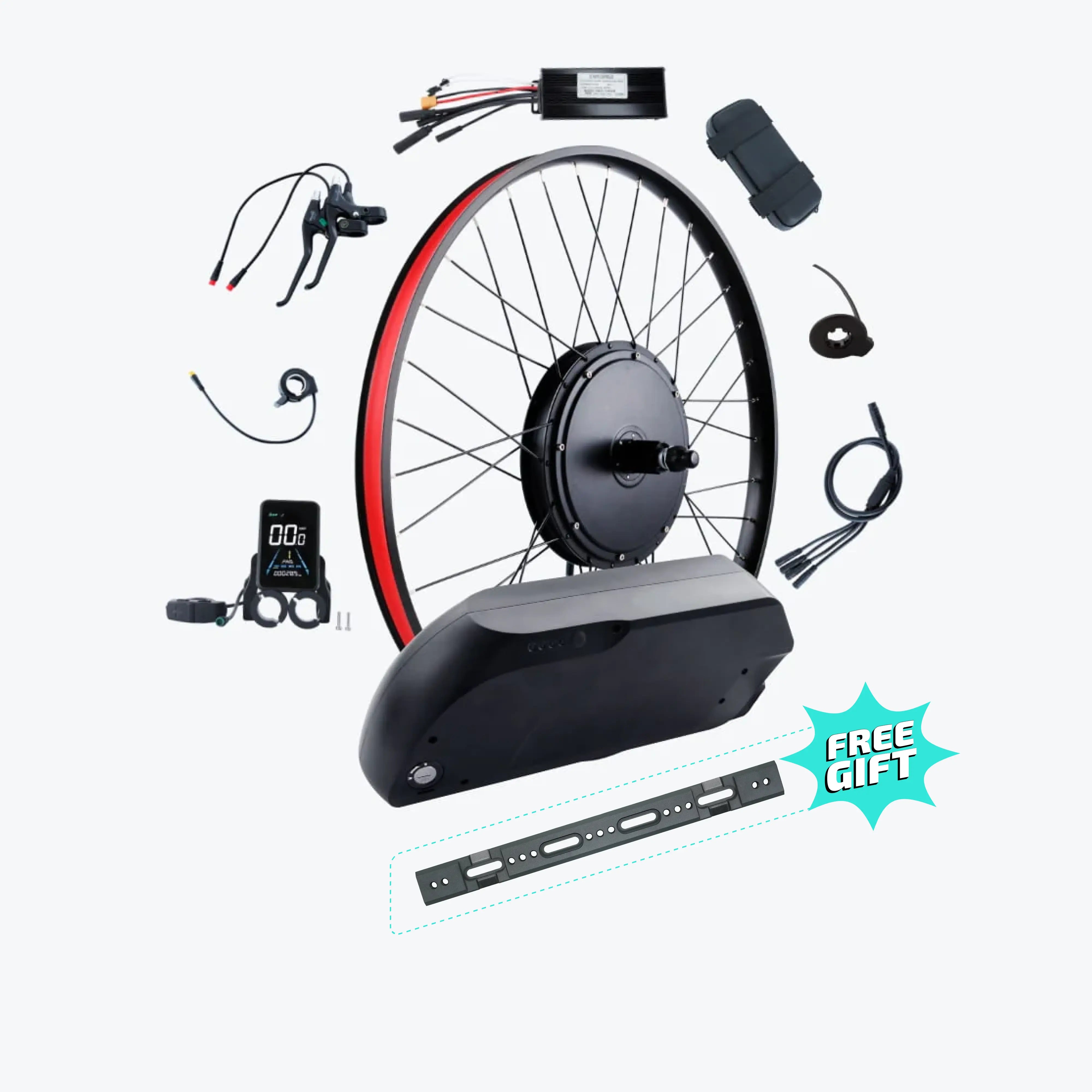

Hydraulic vs Mechanical Disc Brakes

Hydraulic Disc Advantages:

- Superior modulation allows precise control

- Self-adjusting pad clearance maintains performance

- Less hand effort required (critical for long descents)

- Better heat management through sealed system

- More consistent performance in wet conditions

When Mechanical Suffices: For systems below 1500W with minimal hill riding, quality mechanical disc brakes provide adequate performance. However, most riders find hydraulic systems worth the investment for improved control and reduced hand fatigue.

Rotor Upgrade Considerations

Larger rotors provide exponentially better stopping power and heat dissipation—critical factors for high-power e-bikes.

Rotor Size Impact

Heat Dissipation Capacity:

- 160mm rotor: Adequate for 1000W systems, light use

- 180mm rotor: Suitable for 1500W-2000W, moderate use

- 203mm rotor: Required for 2500W+, sustained high-speed riding

- 220mm rotor: Extreme applications, downhill, very heavy loads

Mounting Compatibility: Most bicycle frames support either 160mm or 180mm rotors natively. Upgrading to 203mm typically requires adapter brackets. Verify your frame and fork accept larger rotors before purchasing.

Rotor Material Selection

Stainless Steel (Standard):

- Adequate for most applications

- Good balance of cost and performance

- Sufficient heat capacity for typical riding

- Moderate pad wear rates

Two-Piece Floating Rotors:

- Aluminum carrier with steel braking surface

- Superior heat dissipation through design

- Reduced unsprung weight improves handling

- Better performance on long descents

- Recommended for 2500W+ systems

Heat-Treated Options: Some manufacturers offer heat-treated rotors with improved high-temperature performance. These benefit riders who regularly exhaust brake capacity on long descents.

Brake Caliper and Pad Upgrades

Rotor size alone doesn't determine braking performance—caliper design and pad material dramatically affect stopping power.

Two-Piston vs Four-Piston Calipers

Two-Piston Design:

- Adequate for systems up to 2000W

- Lighter weight preserves handling

- Lower cost for quality units

- Sufficient for most recreational riding

Four-Piston Design:

- Essential for 3000W+ systems

- Dramatically increased pad contact area

- Better heat distribution prevents fade

- More consistent modulation under load

- Recommended for sustained high-speed use

Brake Pad Material Comparison

Organic/Resin Pads:

- Quieter operation

- Better initial bite

- Less rotor wear

- Shorter lifespan, especially under heavy use

- Not recommended for high-power applications above 1500W

Semi-Metallic Pads:

- Balanced performance and longevity

- Adequate heat resistance for moderate use

- Suitable for 1500W-2000W systems

- Reasonable cost

Sintered Metal Pads:

- Superior heat resistance prevents fade

- Excellent wet weather performance

- Longer lifespan under demanding use

- Essential for 2000W+ systems

- Noisier operation

- Higher rotor wear (acceptable tradeoff for safety)

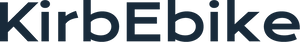

Wheel Construction Requirements

High-power motors place enormous stress on wheel structures. Standard machine-built wheels typically fail within months of high-power use.

Spoke Count and Gauge Standards

Minimum Spoke Requirements:

|

Motor Power |

Front Wheel |

Rear/Motor Wheel |

Spoke Gauge |

|

1000W-1500W |

32 spokes |

36 spokes |

13g (2.3mm) |

|

1500W-2000W |

36 spokes |

36 spokes |

12-13g (2.3-2.6mm) |

|

2000W-3000W |

36 spokes |

48 spokes |

12g (2.6mm) |

|

3000W-4000W |

36-48 spokes |

48 spokes |

11-12g (2.6-3.0mm) |

Why Spoke Count Matters: Each spoke carries a portion of total load. More spokes distribute forces across more connection points, reducing stress per spoke. This becomes critical during hard acceleration when torque loads dramatically increase spoke tension on the drive side.

Rim Material and Construction

Double-Wall Aluminum Rims:

- Minimum standard for any e-bike conversion

- Single-wall rims fail rapidly under high-power use

- Look for eyeletted spoke holes for strength

- Wider internal width (25mm+) improves tire support

Triple-Wall Rims:

- Additional internal support structures

- Better resistance to side impacts

- Recommended for 2500W+ systems

- Particularly valuable for off-road applications

Carbon Fiber Considerations: While lightweight, carbon wheels require careful selection for high-power use. Many carbon rims aren't designed for sustained high-speed braking heat. If choosing carbon, verify the manufacturer rates them for e-bike application with your specific power level.

Hub Selection for Strength

The hub must withstand motor torque transmitted through spokes while supporting the rider's weight and handling side loads from cornering.

Hub Shell Design

Standard Hubs vs E-Bike Specific:

- E-bike rated hubs feature reinforced spoke flanges

- Thicker axles resist bending under load

- Higher-quality bearings handle increased speeds

- Sealed cartridge bearings protect from contamination

Flange Spacing: Wider hub flange spacing creates stronger wheel triangulation, improving lateral stiffness and spoke angle. This helps resist the twisting forces from powerful motors.

Axle Standards

Quick Release vs Thru-Axle:

- Quick release adequate for front wheels on systems below 2000W

- Thru-axle strongly recommended for all rear/motor wheels

- 12mm or 15mm thru-axles provide dramatically better stiffness

- Essential for maintaining wheel alignment under power

Rim Width and Tire Compatibility

Wider rims provide better tire support, improving handling and reducing pinch flat risk—both important for high-power applications.

Internal Rim Width Guidelines

Optimal Width by Application:

- Road/commuter e-bikes: 19-23mm internal width

- Mixed terrain: 23-28mm internal width

- Mountain/off-road: 28-35mm internal width

- Fat tire applications: 60-80mm internal width

Tire Compatibility: Match tire width to rim internal width for optimal performance:

- 19-21mm rim: 28-35mm tires

- 23-25mm rim: 32-42mm tires

- 25-28mm rim: 40-50mm tires

- 28mm+ rim: 50mm+ tires

Proper rim-tire matching improves handling characteristics and reduces the likelihood of burping (tire losing air seal) during hard cornering.

Professional Wheel Building vs Pre-Built

The quality of wheel construction directly impacts longevity under high-power use.

Hand-Built Wheel Advantages

Superior Tension Uniformity: Professional wheel builders achieve spoke tension consistency within 5%, versus 15-20% variance in machine-built wheels. Uniform tension prevents premature spoke failure.

Proper Stress Relieving: Hand builders stress-relieve wheels during construction, pre-stretching spokes to eliminate initial settling that loosens machine-built wheels.

Custom Specifications: Hand-built wheels can use optimal components for your specific:

- Motor power level

- Rider weight

- Terrain type

- Riding style

When Pre-Built Works: Quality factory wheels from reputable e-bike component manufacturers work well for systems up to 2000W with proper maintenance. Above 2500W, custom-built wheels become increasingly important for reliability.

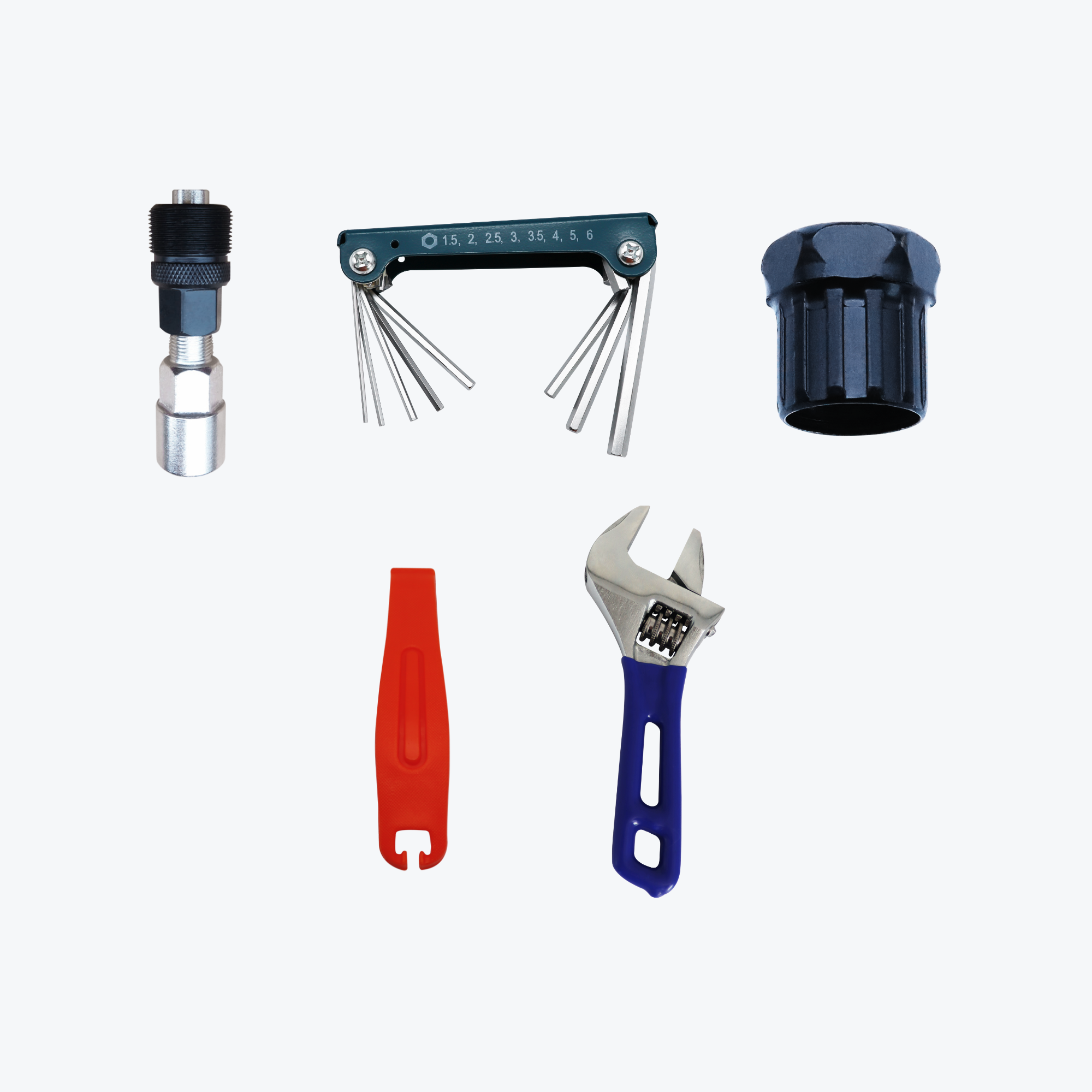

Torque Arms: Essential Safety Equipment

Torque arms prevent motor torque from pulling dropouts out of frame alignment or causing catastrophic frame failure. They're mandatory safety equipment for high-power conversions.

Torque Arm Requirements by Power

750W-1500W:

- Single torque arm acceptable

- Must attach to frame or fork securely

- Steel construction minimum

1500W-2500W:

- Dual torque arms strongly recommended

- Attachment to multiple frame points

- Heavy-duty construction required

2500W+:

- Dual torque arms mandatory

- Consider custom fabrication for optimal fit

- May require frame reinforcement at attachment points

Installation Critical Points:

- Torque arms must mount to frame, not just axle

- Use all mounting points provided

- Apply appropriate threadlocker to bolts

- Inspect regularly for any movement or loosening

Conclusion

Successfully installing a high power ebike kit requires more than just bolting on a motor and battery. The brakes and wheels represent your primary safety systems, and upgrading them appropriately for your power level isn't optional—it's essential.

While the investment in quality hydraulic brakes, larger rotors, and properly built wheels adds to your conversion cost, these components determine whether you safely enjoy your e-bike's performance or experience dangerous brake fade and wheel failure.

By matching your brake and wheel specifications to your motor power level and maintaining them properly, you ensure every ride delivers both the thrill of electric power and the confidence that comes from components equal to the task.

Frequently Asked Questions

Do I really need to upgrade brakes if my motor is only 1500W?

Yes, even 1500W systems reach speeds requiring better stopping power than standard bicycle brakes provide. At minimum, upgrade to 180mm rotors and sintered pads. The modest investment prevents dangerous situations when you need maximum braking performance.

Can I use my existing wheels with a high-power conversion kit?

tandard 32-spoke machine-built wheels typically work for 1000W systems but often fail within months under 1500W+ power. Check your current spoke count and gauge—if less than specifications in this guide, budget for wheel upgrades before spoke failures occur.

How do I know if my frame can handle upgraded brakes and larger rotors?

Check frame specifications for maximum rotor size support. Most frames accommodate 180mm rotors, but 203mm often requires adapters. Ensure your frame has proper mounting points and clearance before purchasing larger components.

Should I upgrade brakes and wheels before installing the motor?

Ideally yes, especially for high-power systems. Installing your motor on upgraded components prevents the risk of riding with inadequate safety equipment. However, many riders upgrade brakes first, then wheels as budget allows.

Are torque arms really necessary for all power levels?

Torque arms become increasingly critical as power increases. For 750W-1000W, they're recommended. Above 1500W, they're mandatory—motor torque can and will damage frame dropouts without proper torque arm support, potentially causing catastrophic frame failure.

How much should I budget for proper brake and wheel upgrades?

Budget roughly: hydraulic brake conversion (both wheels) around the mid-range cost, quality hand-built wheels (pair) at moderate expense, larger rotors and pads relatively affordable. Total investment varies with power level but represents essential safety spending, not optional accessories.

Can I mix brake rotor sizes front and rear?

Yes, and often recommended. Many high-power setups use larger rotors on the front (203mm) than rear (180mm) since front brakes provide most stopping power. This balances performance with weight and cost considerations effectively.