Rear hub motor e-bike conversion represents the most popular electric bicycle transformation globally—delivering superior traction physics favor rear-wheel-drive, balanced natural handling preserving traditional bicycle dynamics, unlimited power capability enabling 250W-4000W range serving gentle assistance through extreme performance, and versatile all-around capability making rear placement optimal for 80% of conversion applications despite requiring moderate installation complexity (25-30 minutes, cassette transfer, derailleur adjustment).

Understanding what makes choosing the best ebike kit with rear hub motor optimal most riders requires examining traction advantages physics creates, power scalability rear placement enables, installation requirements including torque arm considerations, handling characteristics compared to front motors, and honest performance expectations across varied terrain, rider weights, and power levels ensuring informed selection matching rear motor capability to actual cycling needs delivering reliable long-term satisfaction rather than assumptions about "better" disconnected from application realities.

Why Rear Hub Motors Dominate Conversions

Physics Favors Rear Traction

Weight Transfer Mechanics:

During acceleration and climbing, physics shifts weight rearward—increasing rear wheel loading precisely when motor demands maximum traction:

The Traction Advantage:

- Acceleration: Inertia shifts weight rearward → rear wheel loading increases → traction improves

- Climbing: Gravity shifts weight rearward → rear wheel pressed into surface → grip maximizes

- Combined: Acceleration up hills = maximum rear loading, optimal traction conditions

- Front-wheel contrast: Weight shifts away from front → traction reduces when needed most

Real-World Traction Performance:

|

Condition |

Rear Hub Motor |

Front Hub Motor |

Advantage |

|

Dry flat acceleration |

Excellent |

Excellent |

Equal |

|

Wet flat acceleration |

Excellent |

Good (occasional slip) |

Rear (better) |

|

Dry 8% hill start |

Excellent |

Good (adequate) |

Rear (physics helps) |

|

Wet 8% hill start |

Good |

Marginal (slip common) |

Rear (clear advantage) |

|

Dry 12% hill climbing |

Excellent |

Poor (struggles) |

Rear (substantial) |

|

Wet 12% hill climbing |

Good |

Very poor (frequent slip) |

Rear (dramatic advantage) |

|

Loose gravel/dirt |

Good |

Poor (breaks traction) |

Rear (usable vs unusable) |

Unlimited Power Capability

No Traction Ceiling:

Rear placement enables any power level:

Power Range Available:

- 250W: Legal compliance (UK/EU road legal)

- 500-750W: All-around versatility (most popular)

- 1000W: Performance focus (hills, heavy riders)

- 1500-2000W: Serious capability (steep terrain, cargo)

- 2500-4000W: Extreme performance (private property only)

Front Motor Limitation:

Front-wheel-drive limited to 500W practical maximum—beyond creates constant wheel slip regardless of motor quality making rear placement essential applications requiring 750W+ power.

Natural Balanced Handling

Weight Distribution:

Rear motor maintains traditional bicycle balance:

Handling Characteristics:

- Front wheel: Unweighted (responsive steering preserved)

- Weight position: Low and rearward (traditional balance)

- Steering feel: Light natural (unchanged from original)

- Suspension performance: Front suspension unaffected (MTB critical)

- Professional feel: Bicycle dynamics maintained

Contrast Front Motor:

Front motor adds 2.7-4.5kg front wheel creating front-heavy handling requiring adaptation period 50-200km before feeling natural—rear motor feels immediately familiar.

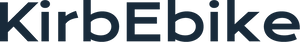

Kirbebike Rear Hub Motor Systems

Geared Hub Motors: 500-750W Range

500-750W SHENGYI Geared Rear Hub:

Most popular configuration serving vast majority excellently:

Ideal Applications: ✓ Mixed flat and hilly terrain (8-15% grades) ✓ All-around cycling (commuting, recreation, errands) ✓ Average riders (70-90kg) ✓ Moderate distances (10-30km daily) ✓ Balanced performance (adequate capability, reasonable weight)

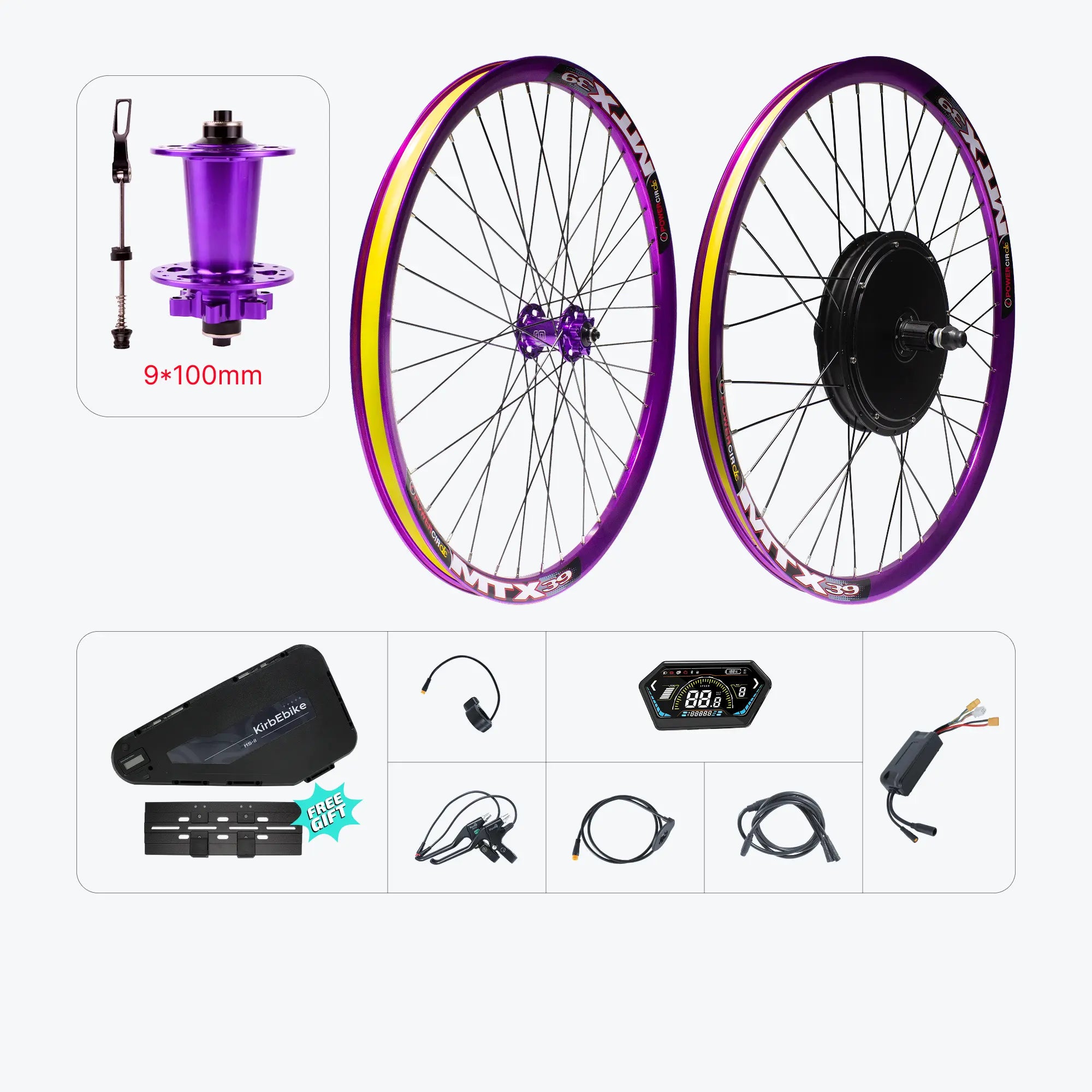

Direct-Drive Hub Motors: 1000W-4000W Range

48V 1000W Direct-Drive:

Performance step-up maintaining moderate weight:

Specifications:

- Motor weight: 4-6.2kg

- Speed: 45-50 km/h

- Hills: 15-20% grades capable

- Battery: 48V 16-20Ah

- Range: 35-50km

- Application: Performance, heavy riders (90-110kg)

52V 2000W Direct-Drive:

Serious capability for demanding applications:

Specifications:

- Motor weight: 5.1-5.3kg

- Speed: 50-60 km/h

- Hills: Any grade conquered

- Battery: 52V 20-30Ah

- Range: 40-60km

- Application: Steep terrain, heavy riders (100kg+), cargo

60V 2500-3000W Direct-Drive:

High performance for extreme applications:

Specifications:

- Motor weight: 6.8kg (maximum heat capacity)

- Speed: 75-85 km/h

- Hills: Unstoppable

- Battery: 60V 20Ah

- Range: 40-80km

- Application: Maximum capability, private property

72V 4000W Direct-Drive:

Ultimate power for specialized needs:

Installation Process: Rear Hub Motor

Tools and Skills Required

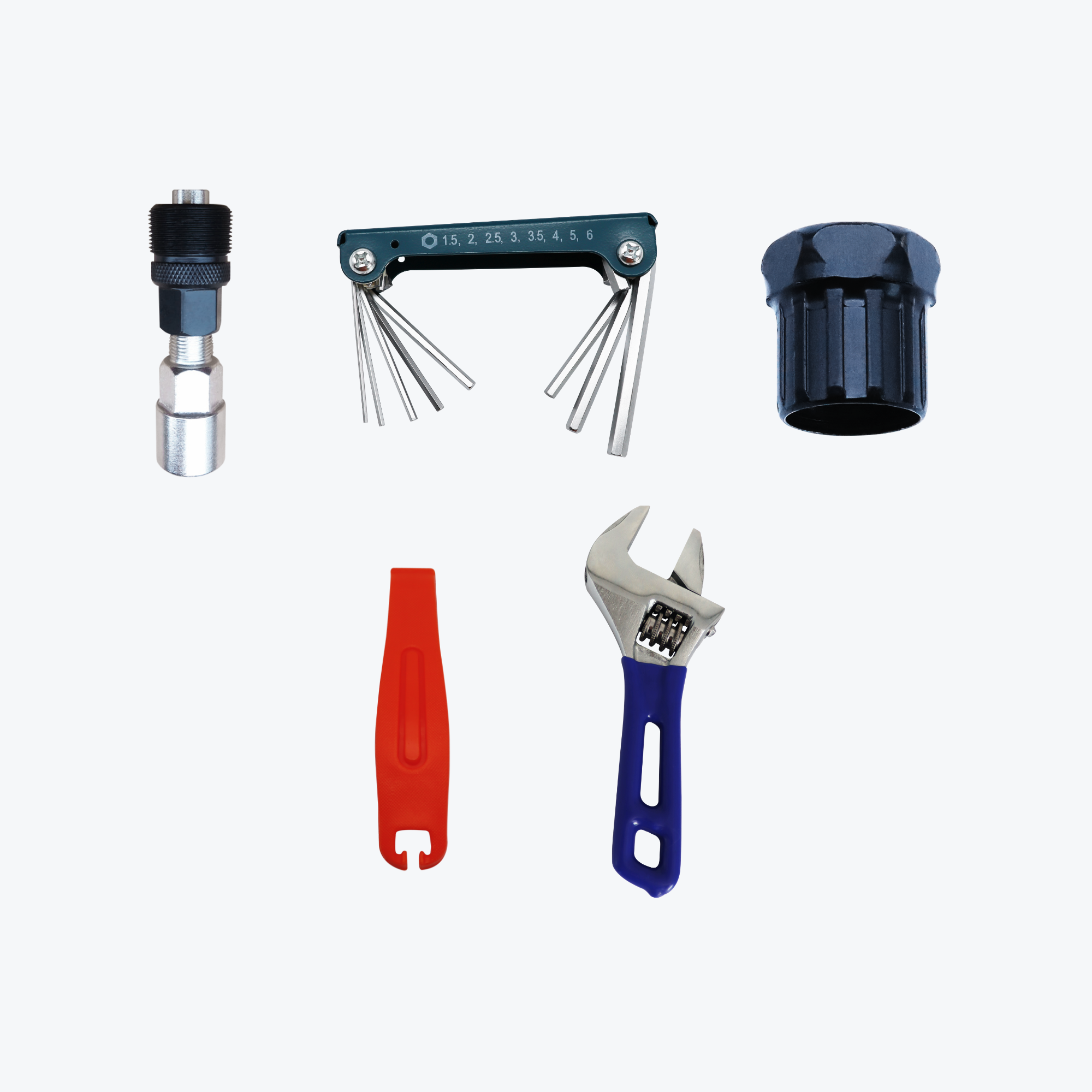

Essential Tools:

- Cassette removal tool (included in kit)

- Chain whip (hold cassette, included)

- Adjustable wrench or 15mm wrench (axle nuts)

- Allen keys (various sizes)

- Cable ties (cable management)

- Torque arms (750W+, included high-power kits)

Skill Level: Moderate mechanical comfort—experience with bicycle maintenance helpful but comprehensive video tutorials enable first-time success.

Installation Time: 25-30 minutes experienced, 40-60 minutes first-time

Step-by-Step Installation Guide

Phase 1: Remove Original Rear Wheel (10 Minutes)

Step 1: Prepare Bicycle

- Shift chain to smallest rear cog (eases cassette removal)

- Secure bicycle in work stand or flip upside down

- Release brake (caliper, cantilever, or disc)

Step 2: Remove Wheel

- Loosen axle nuts or release quick-release

- Pull derailleur back (creates clearance)

- Lift wheel out of dropouts (maneuver chain off cassette)

- Set aside original wheel (future restoration)

Phase 2: Transfer Cassette (10 Minutes)

Standard Power (250-500W):

- Tighten axle nuts firmly

- Torque arms optional (recommended safety margin)

High Power (750-1000W):

- Install one torque arm (mandatory safety)

- Position between dropout and frame

- Tighten all bolts securely (prevent rotation)

- Tighten axle nuts firmly

Very High Power (1500W+):

- Install torque arms both sides (mandatory)

- Heavy-duty arms required

- Precise positioning critical

- All bolts maximum tightness

- Verify: Motor cannot rotate in dropouts

Step 7: Adjust Derailleur

- Fine-tune derailleur position (barrel adjuster)

- Check all gears shift smoothly

- Adjust limit screws if necessary

- Test: Shift through entire range

Phase 4: Mount Components and Connect (10 Minutes)

Torque Arm Requirements

Why Torque Arms Essential

Motor Torque Stress:

Powerful motors create extreme rotational force attempting to rotate motor body within dropouts—without reinforcement, dropout failure catastrophic:

Performance Across Power Levels

500-750W Geared Hub: All-Around Champion

Real-World Performance:

Most riders find 500-750W delivers optimal balance:

Capabilities:

- Flat terrain: 35-40 km/h comfortable sustained

- Gentle hills (5-8%): Effortless, maintaining speed

- Moderate hills (8-12%): Confident climbing, adequate power

- Steep hills (12-15%): Manageable with effort (500W), confident (750W)

- Very steep (15%+): Challenging 500W, adequate 750W

- Rider weight: 70-95kg served excellently

- Range: 40-60km realistic mixed terrain

Who This Serves:

80% of e-bike converters—adequate hills without struggle, reasonable speeds without excess, proven reliability, manageable weight (4.5kg), and best overall value making this power range default recommendation.

1000W Direct-Drive: Performance Step

When 1000W Justified:

✓ Regular steep hills (12-18% sustained) ✓ Heavy riders (90-110kg) ✓ Cargo applications (significant loads) ✓ Performance preference (capability valued) ✓ Power reserves (comfortable margin)

Capabilities:

- Hills: 15-20% conquered confidently

- Speed: 45-50 km/h capability

- Weight: 4-6.2kg (moderate increase)

- Range: 35-50km (higher consumption)

2000W+ Direct-Drive: Specialized Applications

Limited Scenarios:

✓ Very heavy riders (110kg+) ✓ Extreme hills (20%+ sustained) ✓ Heavy cargo regular (touring, utility) ✓ Maximum capability priority ✓ Private property use (legal compliance)

Rear vs Front Hub Motor Decision

Quick Comparison Table

|

Factor |

Rear Hub Motor |

Front Hub Motor |

Better Choice |

|

Installation Time |

25-30 min |

20 min |

Front (simpler) |

|

Installation Complexity |

Moderate (cassette transfer) |

Basic (wheel swap only) |

Front (easier) |

|

Traction All Conditions |

Excellent (physics favors) |

Marginal hills/wet |

Rear (clear advantage) |

|

Power Capability |

250W-4000W unlimited |

250-500W ceiling |

Rear (no limit) |

|

Handling |

Natural balanced |

Front-heavy initially |

Rear (familiar) |

|

Drivetrain Compatibility |

Cassette required |

Universal any system |

Front (flexible) |

|

Best For |

Hills, performance, all-around |

Flat urban, simplicity |

Application-dependent |

Decision Framework

Choose Rear Hub Motor When:

✓ Hills regular feature (8%+ sustained grades) ✓ Traction critical (wet conditions, performance) ✓ Power over 500W desired (750W-4000W range) ✓ Natural handling important (balanced weight) ✓ All-around versatility valued (serves most applications) ✓ Moderate mechanical skills (cassette transfer manageable) ✓ Long-term primary bicycle (not temporary trial)

Choose Front Hub Motor When:

✓ Flat terrain predominates (under 5% typical) ✓ Simplicity absolute priority (first conversion) ✓ Internal gear hub present (preserve expensive component) ✓ Temporary conversion (rental bike, seasonal) ✓ Universal compatibility needed (belt drive, unusual systems) ✓ Quick installation/removal (20 minutes vs 30)

Real-World Rear Hub Success Stories

500W Geared: Perfect All-Around

Rider Profile:

- Weight: 82kg

- Terrain: Mixed urban with 8-12% hills

- Distance: 16km each way daily

- System: 500W SHENGYI geared rear hub

- Battery: 48V 13Ah

Results After 18 Months:

✓ Hills conquered without struggle (adequate power) ✓ Speed comfortable 35-40 km/h urban appropriate ✓ Range 45-50km consistent (exceeds needs) ✓ Reliability perfect (zero issues) ✓ Installation manageable (40 minutes first-time) ✓ Satisfaction complete (serves all needs excellently)

Key Insight: "500W geared rear hub sweet spot—adequate hills, reasonable speeds, proven reliable, perfect balance for mixed-terrain commuting without unnecessary power or complexity."

1000W Direct-Drive: Heavy Rider Solution

Rider Profile:

- Weight: 105kg

- Previous: 750W inadequate (struggled hills)

- System: 48V 1000W direct-drive

- Terrain: 12-15% sustained grades regular

Results After 12 Months:

✓ Hills confident (power reserves comfortable) ✓ No more struggling (adequate capability) ✓ Thermal management perfect (not constantly maxed) ✓ Reliability excellent (heavy-duty construction) ✓ Satisfaction transformative (vs inadequate 750W)

Key Insight: "Heavy riders need adequate power reserves—1000W operates 70-80% capacity (optimal thermal), 750W constantly maxed created thermal stress and disappointing performance despite quality motor."

Making Your Decision

The fundamental principle guiding rear motor selection: power and terrain matching determines optimal system—500-750W geared hubs serve vast majority excellently (mixed terrain, all-around use, 70-95kg riders), 1000W direct-drive addresses performance needs (serious hills, heavy riders 90-110kg, capability priority).

and 2000W+ serves specialized applications (extreme hills, very heavy riders 110kg+, maximum capability) making informed power selection within rear-motor configuration as critical as choosing rear placement itself ensuring conversion delivers reliable capability matched to actual cycling demands rather than excess or inadequacy creating expense or disappointment.

Ready to transform your cycling with optimal rear hub motor technology? Explore the complete electric bike kit battery range including 500-750W SHENGYI geared systems (all-around excellence), 1000W-4000W direct-drive options (performance capability), comprehensive installation support, and expert guidance ensuring your conversion delivers superior traction, appropriate power, and long-term satisfaction through rear motor placement physics and capability favor for demanding cycling applications.

Frequently Asked Questions

Why are rear hub motors better than front hub motors for e-bike conversion?

Physics favors rear traction—acceleration and climbing shift weight rearward increasing rear wheel loading precisely when motor demands maximum traction, enabling confident performance wet conditions and hills where front motors slip frequently. Additionally.

How difficult is rear hub motor installation compared to front?

Moderately more complex: rear requires cassette transfer (10 minutes, special tool included), derailleur adjustment (5 minutes, tuning), potential torque arms (750W+, 5 minutes each), totaling 25-30 minutes versus front wheel swap only (20 minutes).

Do I need torque arms for rear hub motor?

Depends on power and frame material: 250-500W optional but recommended safety margin, 750W one arm mandatory aluminum frames (recommended steel), 1000-1500W one mandatory two highly recommended all frames, 2000W+ two heavy-duty arms mandatory both sides non-negotiables.

What power rear hub motor do I need: 500W, 750W, or 1000W?

Terrain and rider weight determine optimal: 500-750W serves 80% of riders excellently (mixed terrain including 8-15% hills, 70-95kg riders, all-around use, best value), 1000W necessary regular steep hills (15-20%), heavy riders (90-110kg), or performance priority.

How much range do rear hub motor e-bikes get?

Depends on power, battery, terrain, rider weight: 500-750W with 13-16Ah battery typically 40-60km mixed terrain average rider, 1000W with 16-20Ah battery 35-50km, 2000W+ with 20-30Ah battery 40-80km aggressive use.