E-bike conversion kits transform standard bicycles into electric-powered machines through external motor systems mounted visibly on frames—hub motors built into wheel hubs (250W-4000W) or mid-drive units attached at bottom brackets (500-750W)—creating fundamentally different aesthetics.

maintenance accessibility, upgrade flexibility, and ownership economics compared to factory-integrated e-bikes featuring motors concealed within frame tubes, batteries hidden in downtube cavities, and proprietary components designed for seamless visual integration at substantial cost premiums.

Understanding what makes choosing the best ebike kit with visible external components advantageous versus factory integration requires examining installation realities, aesthetic trade-offs, practical maintenance benefits, long-term flexibility advantages.

and honest cost-value analysis rather than assuming "hidden is better" disconnected from real-world ownership experience, repair accessibility, component upgradeability, and total cost implications that often make visible conversion systems superior choices despite lacking factory e-bike visual seamlessness.

Understanding E-Bike Motor Visibility

Conversion Kits: External Visible Systems

What "Visible Motor" Means:

E-bike conversion kits mount motors externally on standard bicycle frames:

Hub Motor Visibility:

- Motor location: Built into wheel hub (front or rear)

- Visual impact: Wider hub than standard wheels (clearly visible)

- Size: 2.7-6.8kg motor mass within wheel

- Identification: Immediately recognizable as electric

- Cable routing: External wiring visible along frame

- Battery: Mounted externally (frame, rack, or bag)

Mid-Drive Motor Visibility:

- Motor location: Bottom bracket area (center frame)

- Visual impact: Obvious motor unit between cranks

- Size: 4.8kg external motor body

- Identification: Unmistakably electric bicycle

- Cable routing: Wires run along frame to battery

- Battery: External down tube or rack mount

Why Conversion Motors Are Visible:

Fundamental design reality—retrofit systems cannot integrate into frames designed for human power alone:

- Standard frames: Not designed accommodating internal motors

- External mounting: Only practical retrofit method

- Component accessibility: External placement enables maintenance

- Universal compatibility: Works any standard bicycle frame

- No frame modification: Preserves original bicycle structure

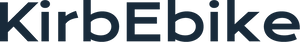

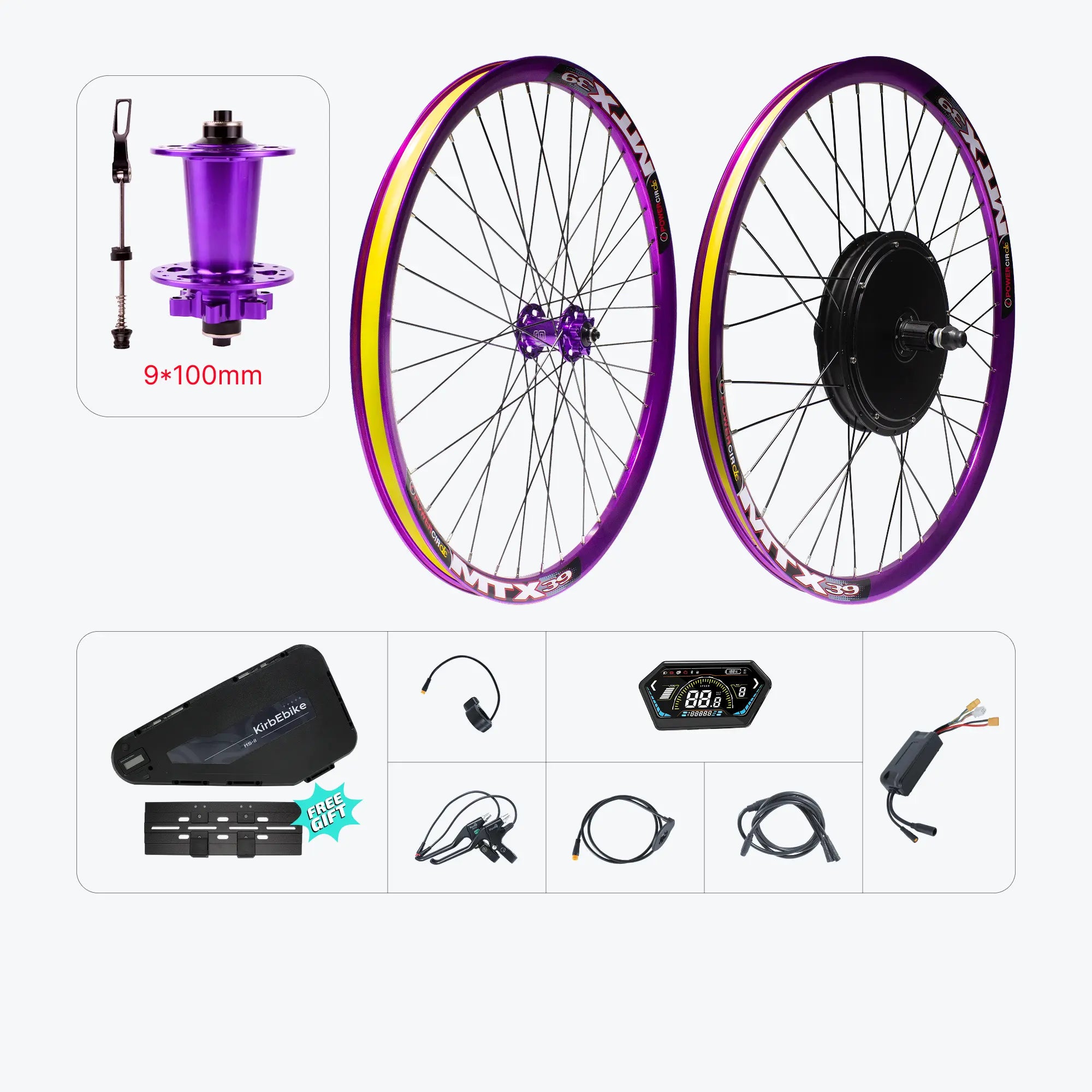

Kirbebike Conversion Systems: Visible External Motors

Hub Motor Systems: Wheel-Mounted Visibility

Front Hub Motors (250W):

Motor clearly visible within front wheel:

Specifications:

- Motor weight: 2.7kg (noticeably wider than standard hub)

- Visibility: Obvious electric conversion (bulkier front wheel)

- Cable routing: From front wheel to handlebar display

- Battery: Frame-mounted externally (down tube or bag)

- Aesthetics: Functional rather than seamless

- Installation: 20 minutes (wheel replacement simplicity)

Rear Hub Motors (500W-4000W):

Motor built into rear wheel hub:

Specifications:

- Motor weight: 4.5-6.8kg (substantial hub mass)

- Visibility: Clearly identifiable electric system

- Cable routing: Chainstay and down tube external

- Battery: External mount (frame, rack options)

- Aesthetics: Visible conversion (obvious motor wheel)

- Installation: 25-30 minutes (cassette transfer required)

Visual Impact Management:

While hub motors remain visible, clean installation minimizes obtrusiveness:

✓ Professional cable routing (neat zip-tie management) ✓ Color-matched components (black wheels, black battery) ✓ Discreet battery placement (integrated frame mount) ✓ Minimal display (small handlebar unit) ✓ Clean wiring (protected, organized, professional)

Mid-Drive Systems: Bottom Bracket Visibility

Tongsheng TSDZ8 (500W-750W):

Motor unit externally mounted at bottom bracket:

Specifications:

- Motor weight: 4.8kg (obvious external component)

- Visibility: Unmistakable mid-drive motor body

- Position: Between cranks (center frame)

- Cable routing: To battery and display externally

- Aesthetics: Functional industrial appearance

- Installation: 30-40 minutes (bottom bracket replacement)

Visual Characteristics:

- Motor casing: Aluminum external housing

- Chainring: Visible front sprocket

- Crank arms: Attached to motor body

- Cables: External routing along frame

- Display: Handlebar-mounted unit

- Overall: Clearly electric bicycle (no concealment)

Aesthetic Comparison Table

|

Feature |

Conversion Kit (Visible) |

Factory E-Bike (Integrated) |

Key Difference |

|

Motor Visibility |

Clearly visible (hub or mid-drive) |

Often concealed OR hub-based (similar visibility) |

Factory may hide mid-drive |

|

Battery Placement |

External frame mount (visible) |

Internal downtube (hidden) |

Factory concealment advantage |

|

Cable Routing |

External along frame |

Internal through tubes |

Factory cleaner appearance |

|

Overall Aesthetics |

Obviously electric |

Often resembles standard bike |

Factory seamless integration |

|

Visual Impact |

Functional industrial look |

Sleek integrated design |

Factory polish advantage |

|

Customization |

Component choice (colors, styles) |

Fixed factory specification |

Conversion flexibility |

|

Professional Finish |

Depends on installation care |

Factory-designed integration |

Factory consistency advantage |

Practical Advantages of Visible Motors

Maintenance Accessibility

Conversion Kit Advantage:

External components enable easy service:

✓ Motor access: Remove wheel (5 minutes) or bottom bracket accessible ✓ Battery service: External mount (quick removal, inspection) ✓ Cable inspection: Visible routing (identify problems immediately) ✓ Controller access: External placement (troubleshooting simple) ✓ Display replacement: Handlebar mount (5-minute swap) ✓ Component upgrades: Straightforward (no frame disassembly)

Factory E-Bike Challenge:

Integrated systems complicate service:

✗ Battery removal: Often requires partial frame disassembly ✗ Motor service: Specialized tools, knowledge required ✗ Internal wiring: Difficult diagnosis, routing complexity ✗ Controller access: May require significant disassembly ✗ Component replacement: Proprietary parts (limited availability)

Upgrade Flexibility

Conversion Kit Advantage:

External systems enable component evolution:

✓ Battery upgrade: Larger capacity (simple swap) ✓ Motor replacement: Different power (wheel or BB swap) ✓ Display upgrade: Better features (handlebar mount change) ✓ Controller upgrade: Enhanced performance (accessible unit) ✓ Incremental improvement: Upgrade piece by piece ✓ Technology adoption: Latest components available

Factory E-Bike Limitation:

Integrated proprietary systems restrict upgrades:

✗ Battery replacement: Expensive proprietary units only ✗ Motor upgrade: Often impractical (integrated frame design) ✗ System improvements: Limited proprietary options ✗ Component obsolescence: Manufacturer discontinuation risk ✗ Total replacement: Often cheaper than major upgrades

Repair Economics

Conversion Kit Advantage:

External visibility simplifies diagnosis and repair:

✓ Problem identification: Visual inspection immediate ✓ Component isolation: Test individual elements easily ✓ Replacement cost: Standard parts (competitive pricing) ✓ DIY repair: Accessible components (owner maintenance possible) ✓ Local service: Any bike shop mechanical work ✓ Long-term viability: Component availability ongoing

Factory E-Bike Challenge:

Integration creates repair complexity:

✗ Diagnosis difficulty: Internal components hidden ✗ Specialized service: Dealer-only repairs common ✗ Proprietary parts: Expensive limited-source components ✗ Labor costs: Frame disassembly time-intensive ✗ Obsolescence risk: Manufacturer support finite ✗ Total replacement: Often economically sensible vs repair

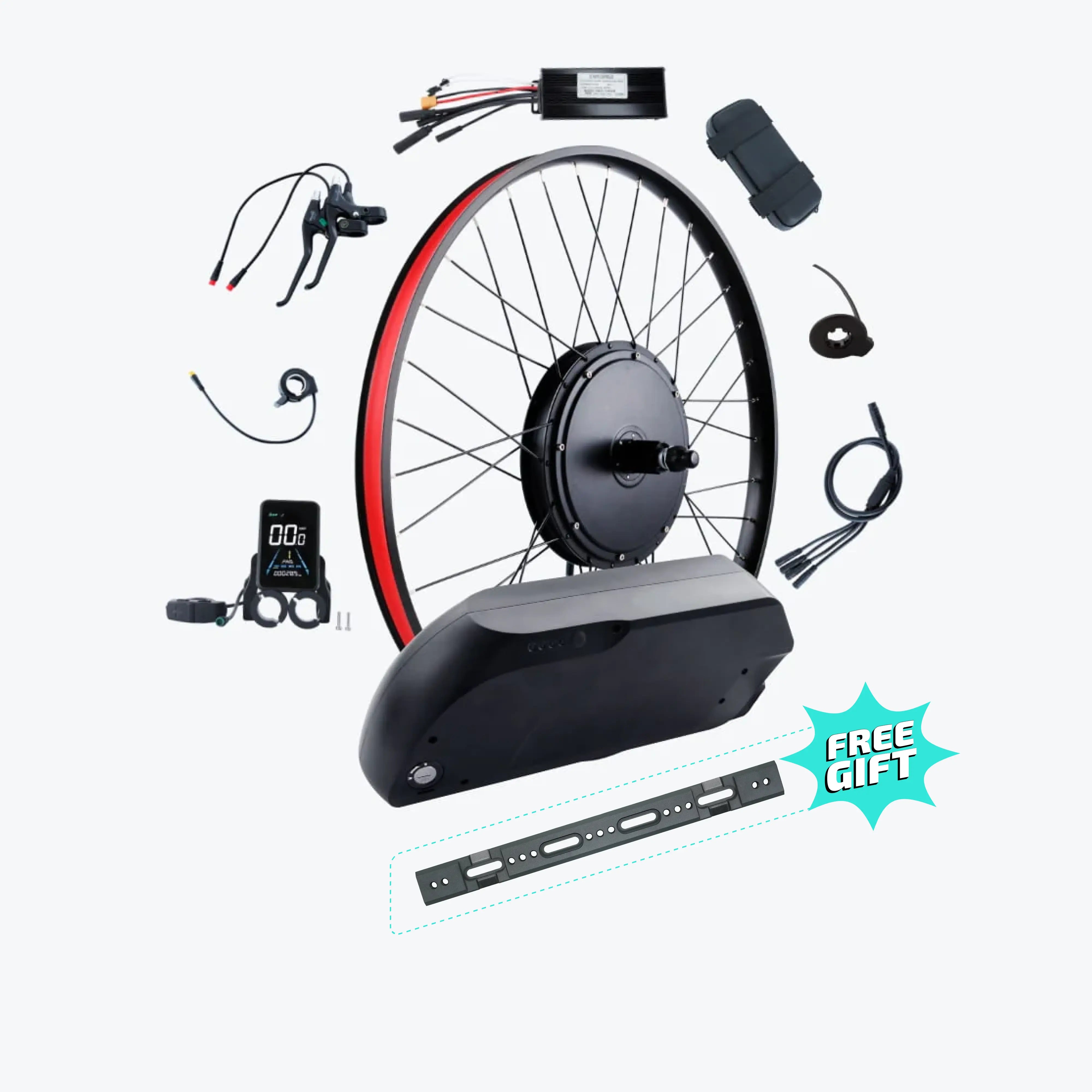

Making Visible Conversions Look Professional

Cable Management Excellence

Professional Installation Techniques:

Clean cable routing minimizes visual clutter:

Best Practices:

- Plan routing: Trace optimal path before installation

- Zip tie spacing: Every 15-20cm (consistent neat appearance)

- Cable protection: Heat shrink, protective sheathing

- Color coordination: Black cables, black ties, black components

- Avoid crossing: Single clean line (no cable spaghetti)

- Secure firmly: Prevent movement, rattling, wear

- Professional finish: Trim zip tie tails, smooth routing

Common Routing Paths:

- Hub motor: Down tube → chainstay → rear wheel OR head tube → fork → front wheel

- Mid-drive: Bottom bracket → down tube → battery

- Display: Handlebars → down tube → controller

- Battery: Down tube mount OR rear rack (clean integration)

Component Color Matching

Visual Cohesion Strategy:

Coordinated component selection minimizes obtrusiveness:

✓ Black wheels: Most discreet motor wheel option ✓ Black battery: Down tube mounts (blends frame) ✓ Black cables: Reduces visual prominence ✓ Small display: Minimal handlebar impact ✓ Frame coordination: Match existing color scheme ✓ Professional appearance: Intentional design (not afterthought)

Battery Placement Optimization

Frame Bag:

- Position: Triangle bag (traditional bikepacking)

- Visibility: Integrated bag appearance

- Aesthetics: Adventure cycling style

- Access: Convenient charging

- Flexibility: Removable complete system

Cost-Value Analysis: Visible vs Integrated

Conversion Kit Economics

Initial Investment:

External visible system costs:

- 250W front hub kit: Entry-level legal compliance

- 500-750W rear hub kit: All-around capability (most popular)

- 1000W+ direct-drive: Performance focus

- Mid-drive 500-750W: Efficiency priority

Value Proposition Reality:

Visible conversion systems often deliver superior long-term value despite lacking factory integration aesthetics—lower initial cost, accessible maintenance, flexible upgrades, standard component availability, and DIY service capability create ownership economics favoring external systems for most riders accepting visible motors as reasonable trade-off for practical advantages and cost savings.

Why Visible Motors Aren't Disadvantages

Honest E-Bike Identification

Transparency Benefits:

Visible motors communicate electric capability clearly:

✓ Legal compliance clarity: Obviously electric (no ambiguity) ✓ Trail courtesy: Other users recognize e-bike (appropriate expectations) ✓ Parking decisions: Security awareness (theft prevention measures) ✓ Insurance honesty: Clear classification (proper coverage) ✓ Resale transparency: Buyers know exactly what purchasing

Enthusiast Pride

Visible Conversion as Achievement:

Many converters appreciate visible systems:

✓ DIY accomplishment: Visible evidence personal work ✓ Technical interest: External components showcase understanding ✓ Conversation starter: Fellow cyclists inquire (community building) ✓ Functional aesthetic: Industrial purposeful appearance valued ✓ Honest engineering: No pretense (genuine electric bicycle)

Maintenance Confidence

External Accessibility:

Visible systems reduce anxiety:

✓ Problem diagnosis: Visual inspection immediate ✓ Component monitoring: Wear patterns observable ✓ DIY capability: Owner maintenance realistic ✓ Service confidence: Understand system (not mysterious black box) ✓ Long-term viability: Component availability assured

Real-World Owner Perspectives

Conversion Kit Owner: Functionality Over Aesthetics

System: 500W Rear Hub Conversion

Owner Reflection:

"Initially concerned about visible motor wheel, but reality is nobody cares except me. Clean cable routing looks professional, external battery convenient charging, and easy maintenance accessibility outweighs seamless integration I thought I wanted. Saved thousands versus factory e-bike, can upgrade components individually, and DIY maintenance saves ongoing costs—visible motor completely irrelevant after first week."

Factory E-Bike Owner: Integration Challenges

System: Mid-Range Integrated E-Bike

Owner Experience:

"Love seamless appearance initially, but battery replacement requires dealer ($800+ proprietary unit), motor issue needs specialized service (3-week wait, $400 diagnosis), and upgrade options non-existent. Friend's visible conversion kit performs identically, costs half, and he services everything himself—reconsidering integration premium value versus practical ownership reality."

Making Your Decision

E-bike conversion kits deliver visible external motor systems (hub motors 250W-4000W within wheel hubs, mid-drive motors 500-750W at bottom brackets) creating obvious electric bicycle appearance contrasting factory-integrated e-bikes concealing motors/batteries within frame tubes—but visible conversion systems offer substantial practical advantages including accessible maintenance (external components service-friendly).

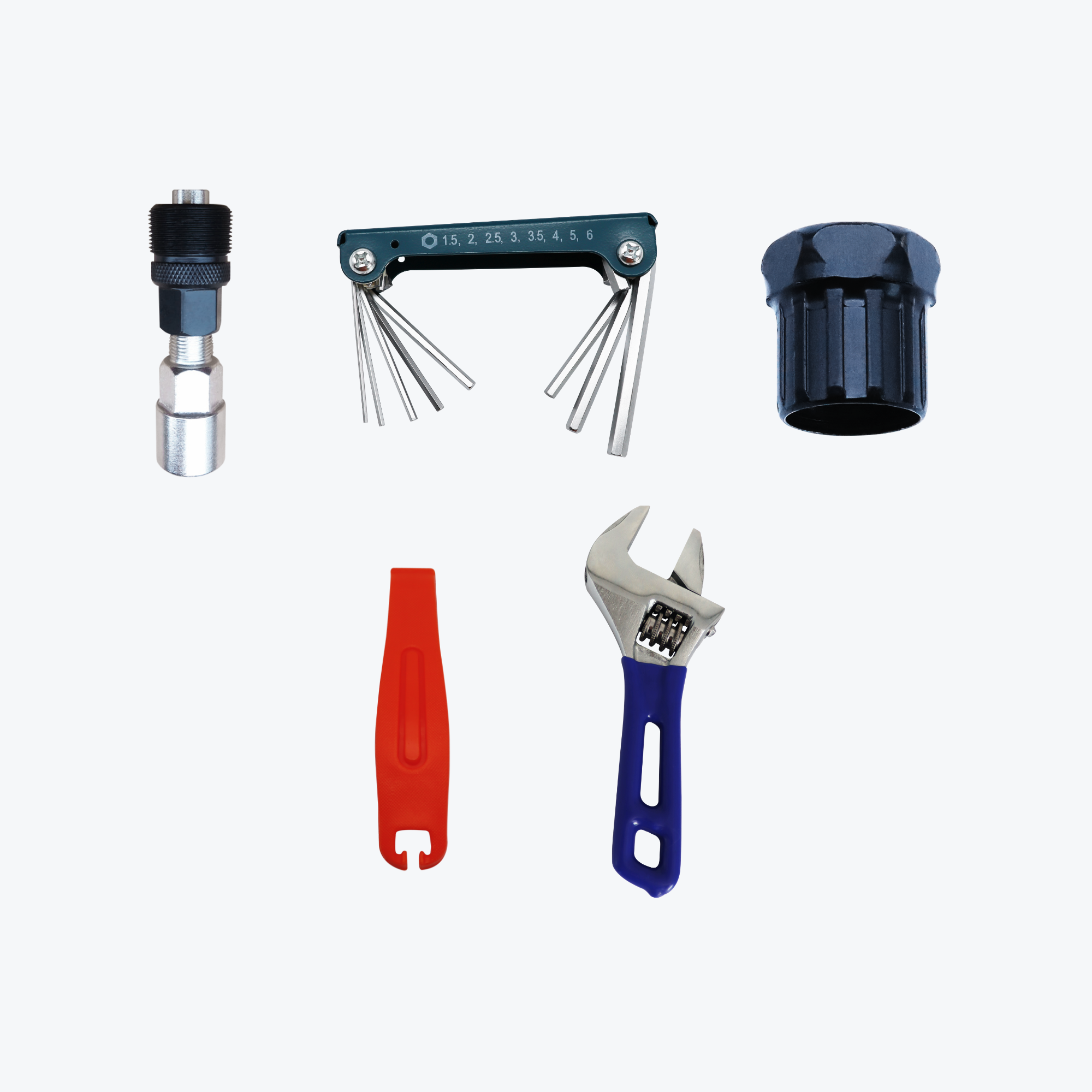

Ready to transform your bicycle with practical visible motor technology? Explore the complete electric bike kit battery range including front hub systems (250W legal-compliant, 20-minute installation, cleanest front-drive aesthetic), rear hub motors (500W-4000W capability, professional appearance through quality installation), mid-drive options (TSDZ8 500-750W.

centered placement, natural integration), and expert installation guidance ensuring your visible conversion delivers professional appearance, accessible maintenance, and long-term satisfaction through honest motor visibility accepting practical advantages outweigh aesthetic concealment most ownership scenarios.

Frequently Asked Questions

Can e-bike conversion kits have hidden motors like factory e-bikes?

No—conversion kits retrofit standard bicycle frames not designed for internal motor integration, requiring external motor mounting (hub motors within wheel hubs 2.7-6.8kg visible, mid-drive motors at bottom brackets 4.8kg obvious).

Do visible motors on conversion kits look ugly or unprofessional?

Subjective—professional installation with clean cable routing, color-matched components (black wheels, black battery, organized wiring), and thoughtful battery placement creates functional purposeful appearance many riders appreciate versus "ugly.

What are the advantages of visible motors on conversion kits?

Maintenance accessibility (external components service-friendly, DIY repairs realistic, problem diagnosis visual immediate), upgrade flexibility (battery/motor/display replaceable independently.

How can I make my e-bike conversion look as clean as possible?

Professional cable routing (consistent zip tie spacing 15-20cm, single clean line along frame tubes, no crossing cables), color coordination (black components, black cables, black battery matching most frames)e.

Are factory e-bikes with hidden motors better than conversion kits?

Depends on priorities—factory integration delivers superior aesthetics (seamless concealed appearance, internal wiring, hidden battery), weather protection (internal components).