Mountain bikes represent ideal candidates for electric conversion—robust frames, quality components, and suspension systems designed for challenging terrain. However, transforming your MTB into an e-bike involves critical considerations that determine whether you'll create a powerful trail machine or encounter frustrating compatibility issues.

Understanding what to watch for prevents costly mistakes and ensures your converted mountain bike delivers the performance you're imagining.Converting your mountain bike offers compelling advantages over purchasing pre-built e-MTBs, particularly the ability to retain your familiar geometry, preferred components, and proven reliability.

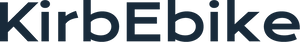

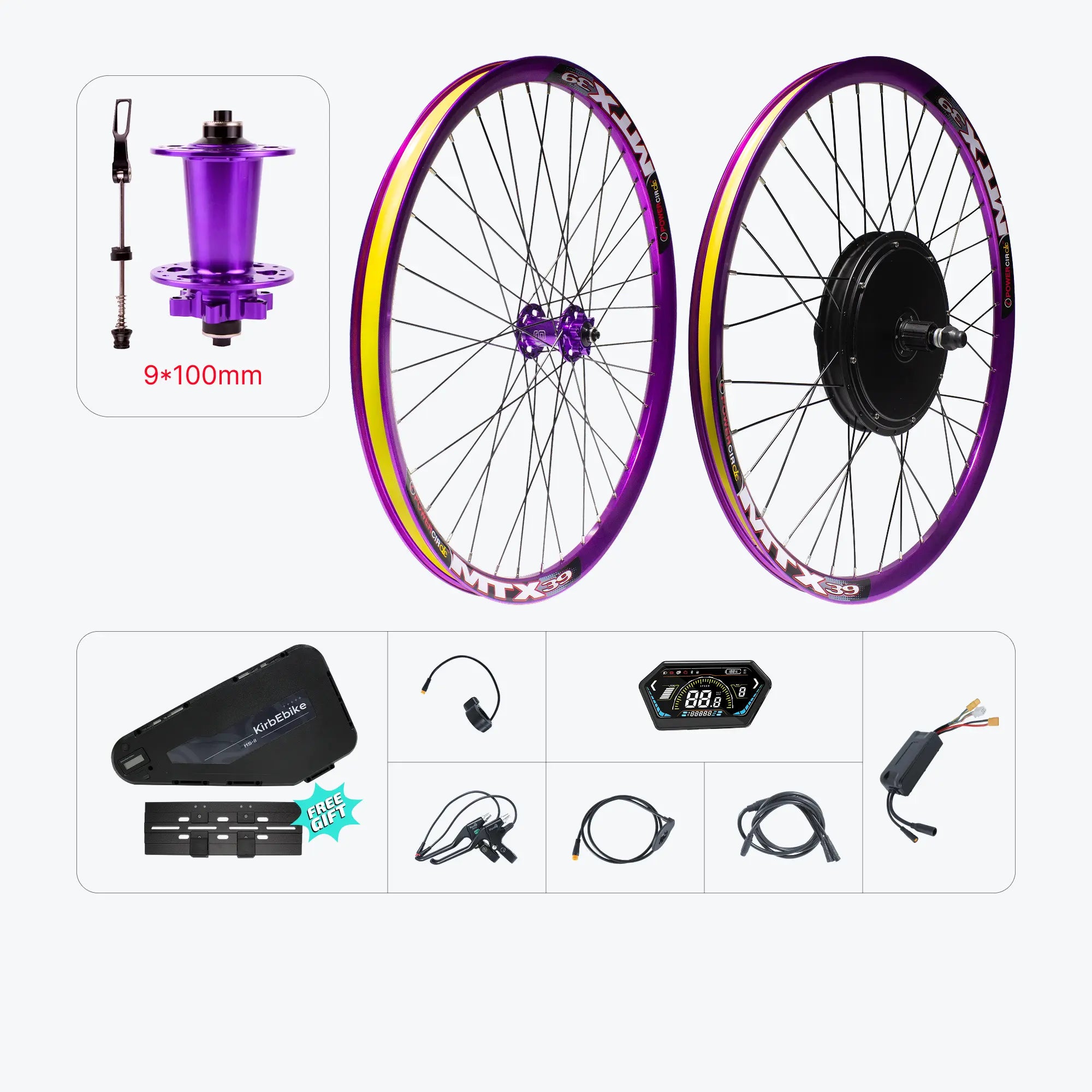

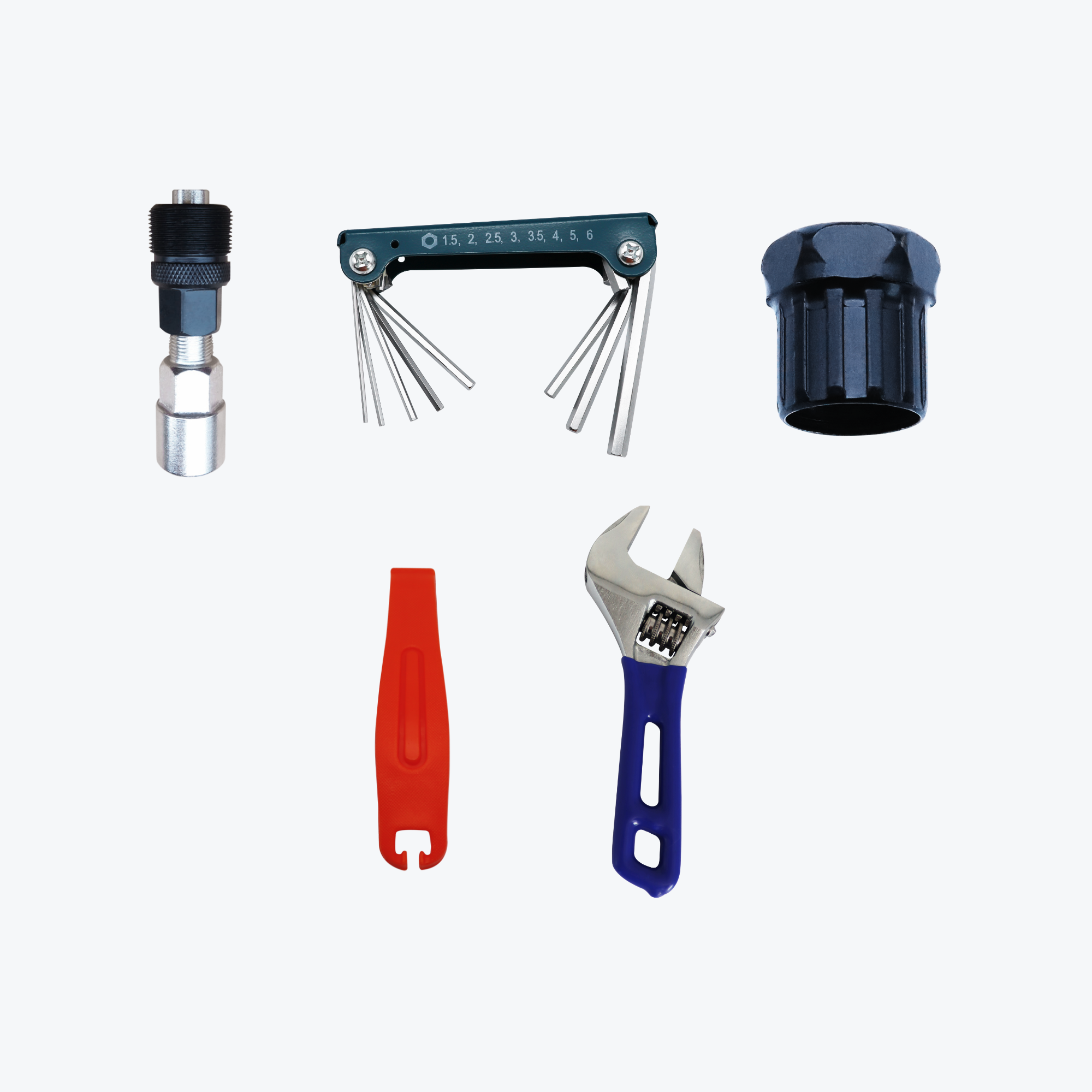

KirbEbike's comprehensive conversion kit range provides mountain bike-specific solutions from 250W legal trail systems to 4000W extreme performance setups. The key lies in matching the right kit to your specific bike while addressing the unique challenges mountain bike conversions present.

Critical Mountain Bike Compatibility Factors

Suspension Type Impact on Conversion Options

Hardtail Mountain Bikes

Hardtail MTBs with rigid rear triangles offer the simplest, most reliable conversion platform. The absence of rear suspension creates straightforward motor mounting, battery placement options, and minimal maintenance complications.

Advantages for conversion:

- Clear battery mounting locations on downtube or rear rack

- Standard rear dropout spacing accepts hub motors easily

- Mid-drive systems mount without suspension interference

- Simpler cable routing without pivot points

- Lower overall weight addition

Full-Suspension Mountain Bikes

Full-suspension conversions introduce substantial complexity but remain entirely feasible with careful planning.

Challenges to address:

- Battery placement without suspension interference

- Cable routing through pivot points

- Potential shock/linkage clearance issues

- Weight distribution affecting suspension performance

- Limited downtube mounting space on some frames

Solution strategies for full-suspension:

- Triangle bags housing batteries between frame tubes

- Downtube batteries on frames with adequate clearance

- Rear rack systems for bikes with strong mounting points

- Mid-drive motors clearing suspension linkages

- Professional assessment of clearances before purchasing

Wheel Size Considerations

Mountain bikes span 26", 27.5" (650B), and 29" wheel formats, each affecting motor selection differently.

26-Inch Wheels:

- Higher torque multiplication (smaller diameter)

- More responsive acceleration

- Slightly reduced top speed

- Excellent for technical climbing

- Hub motors widely available

27.5-Inch Wheels:

- Balanced performance characteristics

- Good acceleration with reasonable top speed

- Universal motor compatibility

- Most versatile conversion option

29-Inch Wheels:

- Higher top speeds from larger diameter

- Better obstacle roll-over capability

- Slightly reduced torque feel

- Requires verification of motor clearance with fork/frame

- Perfect for XC and trail riding

Frame Material Strength Assessment

Mountain bike frame materials respond differently to motor stresses.

|

Frame Material |

Conversion Suitability |

Power Recommendations |

Special Considerations |

|

Aluminum Alloy |

Excellent (modern frames) |

Up to 2000W hub, 1500W mid-drive |

Check dropout thickness, use torque arms |

|

Steel/Chromoly |

Excellent |

Up to 2000W hub, unlimited mid-drive |

Durable, slight weight penalty |

|

Carbon Fiber |

Poor to Fair |

250-500W maximum, avoid unless rated |

Manufacturer warranty void, stress concerns |

|

Titanium |

Good to Excellent |

Up to 1500W with proper mounting |

Rare, expensive, consult frame builder |

Critical inspection points:

- Dropout thickness (minimum 3mm for hub motors)

- Weld quality around stress points

- Previous damage or repair history

- Bottom bracket shell condition for mid-drives

- Frame tube diameter for battery mounting

Motor Type Selection for Mountain Bike Applications

Hub Motor Systems on Mountain Bikes

Rear Hub Motors: The Power Choice

Rear hub motors deliver direct power to the rear wheel, ideal for climbing and acceleration.

Benefits for MTB conversion:

- Direct drive through rear wheel (traction advantage)

- Independent of drivetrain (preserves shifting)

- Simple installation on hardtails

- High power options available (1000-4000W)

- Minimal maintenance requirements

Limitations to consider:

- Adds weight to rear wheel (affects handling)

- Reduces rear axle options (generally 135mm QR)

- Complicates flat tire repairs

- May limit gear range usage

- Requires torque arms for safety

Front Hub Motors: The Compromise

Front hub motors work but present significant compromises for mountain biking.

Why front hubs are less ideal for MTB:

- Reduced traction on climbs (weight distribution)

- Front wheel lift tendency on steep ascents

- Fork stress on rough descents

- Less intuitive power delivery

- Better suited to road/hybrid bikes

Mid-Drive Motors: The Mountain Bike Specialist

Mid-drive systems like the KirbEbike Tongsheng TSDZ8 mid motor kit represent the gold standard for serious mountain bike conversions.

Why mid-drives excel for MTB:

Climbing Performance

- Uses bike's entire gear range

- Maintains efficiency on steep technical climbs

- Natural torque application through cranks

- Weight centered for optimal balance

Technical Riding

- Unsprung weight remains low

- Maintains suspension performance

- Easier wheelies and manual moves

- Preserves bike handling characteristics

Efficiency Benefits

- Better battery range through gear optimization

- Reduced motor strain on varied terrain

- Cooler motor operation

- Extended component life

Mid-drive challenges:

- Increased drivetrain wear (chain, cassette, chainring)

- More complex installation requiring bottom bracket removal

- Higher component quality requirements

- Regular maintenance essential

- Potential for dropped chains on rough terrain

Power Level Recommendations for Mountain Biking

Trail Riding & XC (Cross-Country):

- Recommended: 500-750W mid-drive or 750-1000W hub

- Focus: Extended range, moderate assistance, legal compliance

- Battery: 48V 11-16Ah (500-750Wh)

All-Mountain & Enduro:

- Recommended: 750-1500W mid-drive or 1500-2000W hub

- Focus: Climbing power, technical terrain capability

- Battery: 48-52V 16-20Ah (750-1000Wh)

Downhill & Freeride:

- Recommended: 1500-3000W hub (mid-drives face excessive wear)

- Focus: Maximum power, durability, speed

- Battery: 52-72V 20-30Ah (1000-2000Wh)

Trail Performance Optimization

Weight Distribution Fine-Tuning

Optimal weight distribution maintains mountain bike handling characteristics despite added components.

Target distribution:

- 60-65% rear weight (climbing traction)

- Battery positioned low and central

- Motor weight counterbalancing battery placement

- Rider position maintaining center of gravity

Testing protocol:

- Ride familiar trails noting handling changes

- Adjust battery position if possible

- Modify riding technique for weight differences

- Consider component placement for balance

Power Delivery Settings

Modern conversion kits offer programmable assist levels. Optimizing these settings transforms riding experience.

Recommended MTB assist profiles:

Level 1 - Eco:

- 30-50% assistance

- Maximum range

- Smooth technical sections

- Fire road cruising

Level 2 - Tour:

- 60-80% assistance

- Balanced range and power

- General trail riding

- Moderate climbing

Level 3 - Sport:

- 100-150% assistance

- Steep technical climbs

- Time trial segments

- Power when needed

Level 4 - Turbo:

- 150-250% assistance

- Maximum power delivery

- Extreme climbs

- Short duration bursts

Real-World Mountain Bike Conversion Examples

Trail Hardtail Conversion

Base bike: 27.5" aluminum hardtail Kit: 48V 1000W rear hub motor, 48V 16Ah downtube battery Intended use: XC trail riding with significant climbing

Results: Transformed challenging climbs into manageable efforts while maintaining excellent descending capabilities. Battery life provides 45-55km range on typical trail rides with 600m elevation gain. Standard components handled conversion well with chain replacement at 1500km and brake pads at 2000km.

Full-Suspension All-Mountain Conversion

Base bike: 29" full-suspension trail bike (150mm travel) Kit: 48V 750W Tongsheng TSDZ8 mid-drive, 48V 20Ah triangle bag battery Intended use: Technical singletrack and enduro-style riding

Results: Mid-drive preserved excellent handling characteristics while delivering powerful climbing assistance. Frame bag battery solution maintained suspension performance without interference. Drivetrain wear notable—chain replacement every 1200km, cassette every 2500km. Overall performance exceeded expectations for technical terrain capability.

Fat Bike Extreme Conversion

Base bike: 26" steel fat bike with 4.8" tires Kit: 52V 2000W rear hub, 52V 25Ah downtube battery Intended use: Beach riding, snow trails, extreme terrain

Results: Powerful motor overcame fat tire rolling resistance effortlessly. Robust steel frame handled high power without concern. Battery capacity adequate for 40-50km beach rides. Dual torque arms essential for preventing dropout damage under extreme loads.

Final Conversion Decision Framework

Converting your mountain bike to electric power delivers incredible performance and versatility, but success depends on careful planning. KirbEbike's comprehensive conversion kit selection provides options for every MTB application, from legal trail riding to extreme performance.

Prioritize these decisions:

- Motor type: Mid-drive for technical trails, hub for power and simplicity

- Power level: Match to your steepest regular terrain

- Battery capacity: Calculate based on typical elevation gain

- Component upgrades: Budget for brakes, drivetrain, suspension tuning

- Legal compliance: Understand where you can legally ride your creation

Mountain bike conversions represent some of the most rewarding e-bike projects. The combination of robust frames, quality components, and appropriate terrain creates ideal conditions for electric assist. Watch for the critical factors outlined above, invest in proper components, and maintain your system diligently—your converted mountain bike will deliver years of enhanced trail performance.

Frequently Asked Questions

Can I convert a full-suspension mountain bike or should I stick with a hardtail?

Both work well, but hardtails simplify installation with easier battery mounting and no suspension interference concerns. Full-suspension bikes require triangle bag batteries or creative solutions but maintain superior riding characteristics. Choose based on your preferred riding style rather than conversion complexity.

What power level do I really need for mountain bike trail riding?

For most trail riding with moderate hills, 750-1000W provides excellent performance. Steeper terrain (20%+ grades) benefits from 1000-1500W. Extreme downhill/freeride applications may justify 2000W+, but consider legal restrictions and frame capability before choosing maximum power.

Will a conversion kit void my mountain bike frame warranty?

Almost certainly yes. Most manufacturers specifically void warranties when motors are added, particularly for carbon frames. Use older bikes past warranty periods or frames you're comfortable accepting risk on. Aluminum and steel frames generally tolerate conversion better than carbon.

How much does a mountain bike conversion affect suspension performance?

Adding 5-10kg requires suspension recalibration (increasing air pressure or spring rates), but properly adjusted suspension performs well. Battery placement matters—central, low-mounted batteries minimize impact. Full-suspension bikes need careful battery positioning to avoid interference with rear shock travel.

Do I need a special e-bike chain and cassette for mountain bike conversions?

Mid-drive conversions absolutely require e-bike specific chains and preferably all-steel cassettes. The increased torque and power accelerate wear dramatically—standard components may last only 1000km. Hub motor conversions place less drivetrain stress and work acceptably with quality standard components.

Can I still remove the front wheel easily for transport after installing a front hub motor?

Yes, front hub motors typically use quick-release or through-axle systems allowing normal wheel removal. Disconnect the motor cable connector before removing the wheel. However, front hub motors are generally less recommended for mountain bikes due to traction and handling concerns.

What's the realistic range for mountain bike riding with an e-conversion?

Range varies enormously with terrain. On flat trails, expect 50-70km from a 750Wh battery. Significant climbing (600m+ elevation gain) reduces this to 30-50km. Extreme terrain with maximum power usage may yield only 20-30km. Carry spare batteries for long backcountry rides.