Choosing between 52V and 72V e-bike systems isn't just about numbers—it's about matching power to purpose. While a 52V system delivers excellent performance for most riders, 72V systems push into extreme territory with speeds exceeding 55 mph and power outputs reaching 4000W.

Understanding which voltage suits your riding style can save you money and deliver the performance you actually need.

Understanding Voltage: The Foundation of E-Bike Power

Voltage determines how much electrical potential your e-bike system can deliver. Think of it like water pressure in a hose—higher voltage pushes more energy through the motor, resulting in greater speed and acceleration.

52V systems operate at a nominal 52 volts (58.8V when fully charged) and typically pair with motors ranging from 1500W to 2600W. 72V systems run at 72 volts nominal (84V fully charged) and commonly drive motors from 3000W to 4000W.

The voltage you choose fundamentally shapes your riding experience, influencing everything from hill-climbing ability to top speed and battery efficiency.

Performance Comparison: Real-World Capabilities

Speed and Acceleration

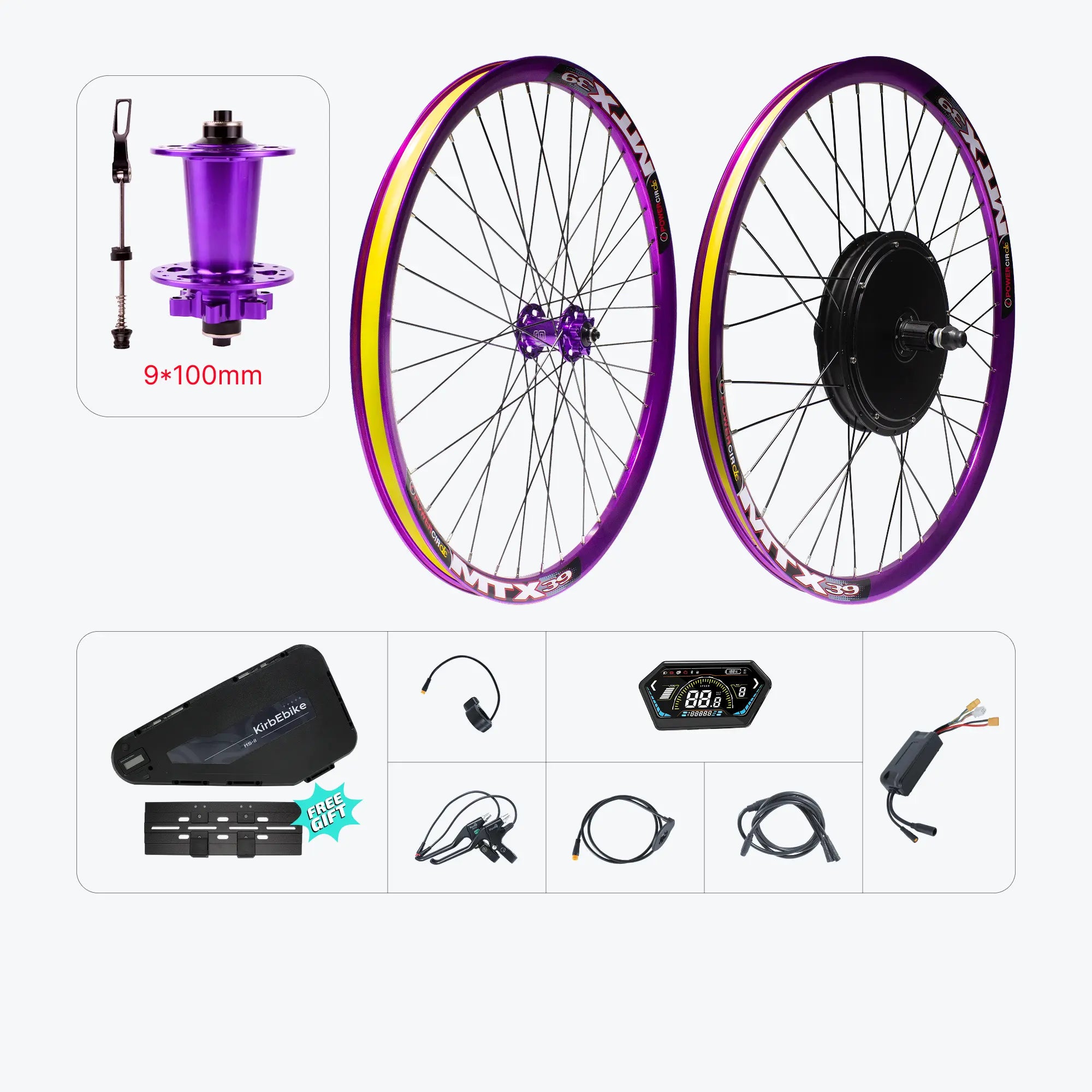

72V systems dominate when raw speed matters. The 72V 4000W extreme performance kit achieves 75-85 km/h (approximately 50+ mph), making it suitable for riders who need highway-level speeds or extreme off-road performance.

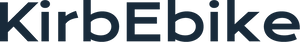

52V systems deliver 50-60 km/h (31-37 mph) with 2000W motors—more than adequate for urban commuting, trail riding, and most recreational applications. The 52V 2000W MTX rim kit provides excellent performance without the complexity and cost of ultra-high voltage.

|

System |

Top Speed |

Acceleration |

Ideal Use Cases |

|

52V 2000W |

50-60 km/h |

Very responsive |

Urban commuting, trail riding, moderate hills |

|

72V 4000W |

75-85 km/h |

Extreme |

Off-road racing, steep terrain, high-speed applications |

Hill Climbing and Torque

Higher voltage translates directly to climbing power. A 72V system maintains strong torque even on steep gradients, making it ideal for mountainous terrain or heavy cargo hauling.

52V systems handle most hills competently. With proper gearing and reasonable rider input, they conquer inclines that would stop conventional bicycles. For riders in moderately hilly areas, 52V provides sufficient climbing ability without excessive weight or cost.

Range Considerations

Range depends on multiple factors: battery capacity, riding style, terrain, and rider weight. However, voltage efficiency plays a crucial role.

52V systems typically use 20-30Ah batteries, delivering 40-60 km range under normal riding conditions. The lower power draw extends battery life per charge.

72V systems with 20Ah batteries offer 40-80 km range, but aggressive riding dramatically reduces this. The higher power output drains batteries faster during hard acceleration and high-speed cruising.

Battery Technology and Specifications

52V Battery Systems

Quality 52V batteries use LG 21700 cells configured in a 14S arrangement (14 cells in series). These batteries deliver:

- Capacity options: 20Ah, 25Ah, 30Ah

- Cycle life: 1000+ charge cycles

- Weight: Approximately 3-4.5 kg depending on capacity

- Charging time: 4-8 hours with standard chargers

The moderate voltage places less stress on cells, potentially extending overall battery lifespan compared to higher-voltage systems.

72V Battery Systems

72V batteries require a 20S cell configuration, increasing complexity and cost. Specifications include:

- Capacity options: Typically 20Ah

- Cycle life: 800-1000 cycles

- Weight: Approximately 5-6 kg

- Charging time: 6-10 hours with standard chargers

The higher voltage demands robust battery management systems (BMS) to prevent cell imbalance and ensure safe operation.

Cost Analysis: Initial Investment and Long-Term Value

Upfront Costs

72V systems command premium pricing due to specialized components. The motor, controller, and battery all require higher-grade materials to handle increased electrical stress.

52V systems offer excellent value, delivering strong performance at more accessible price points. For most riders, the 52V ebike battery configurations provide optimal cost-to-performance ratios.

Operating Costs

Controller efficiency: 72V controllers typically run at 85-90% efficiency, while quality 52V controllers achieve 90-95% efficiency. This difference impacts range and electricity costs over time.

Battery replacement: 72V batteries cost more to replace and may require replacement sooner due to higher discharge rates. 52V batteries generally last longer under normal use conditions.

Maintenance: Higher-power 72V systems generate more heat, potentially accelerating wear on motors and controllers. More frequent inspections and earlier component replacement may be necessary.

Safety and Legal Considerations

Power Restrictions

Many jurisdictions limit e-bike power to 750W or 1000W for road use. 72V 4000W systems significantly exceed these limits, restricting legal operation to private property or designated off-road areas.

52V 2000W systems also exceed most legal limits but operate closer to acceptable ranges. Some regions permit higher-powered e-bikes with proper registration and licensing.

Electrical Safety

Higher voltage increases electrical hazards. 72V systems require:

- High-quality insulated wiring

- Proper connector ratings (60A+ continuous)

- Robust fuse protection

- Careful installation to prevent shorts

52V systems, while still requiring proper installation, present somewhat lower electrical risks and are more forgiving of minor installation errors.

Component Requirements and Compatibility

Motor Considerations

52V motors typically feature:

- Direct drive or geared hub designs

- Power ratings: 1500-2600W

- Weight: 5-6 kg

- Standard spoke patterns compatible with most wheels

72V motors require:

- Heavy-duty direct drive hubs

- Power ratings: 3000-4000W

- Weight: 6.8+ kg

- Reinforced spoke patterns and stronger rims

Controller Specifications

Controllers must match system voltage precisely. A 52V controller cannot safely operate on 72V, and vice versa.

52V controllers handle 30-50A continuous current, providing adequate power delivery for 2000W motors without excessive heat generation.

72V controllers manage 50-60A+ continuous current, requiring substantial heat sinking and often active cooling for sustained high-power operation.

Display and Accessories

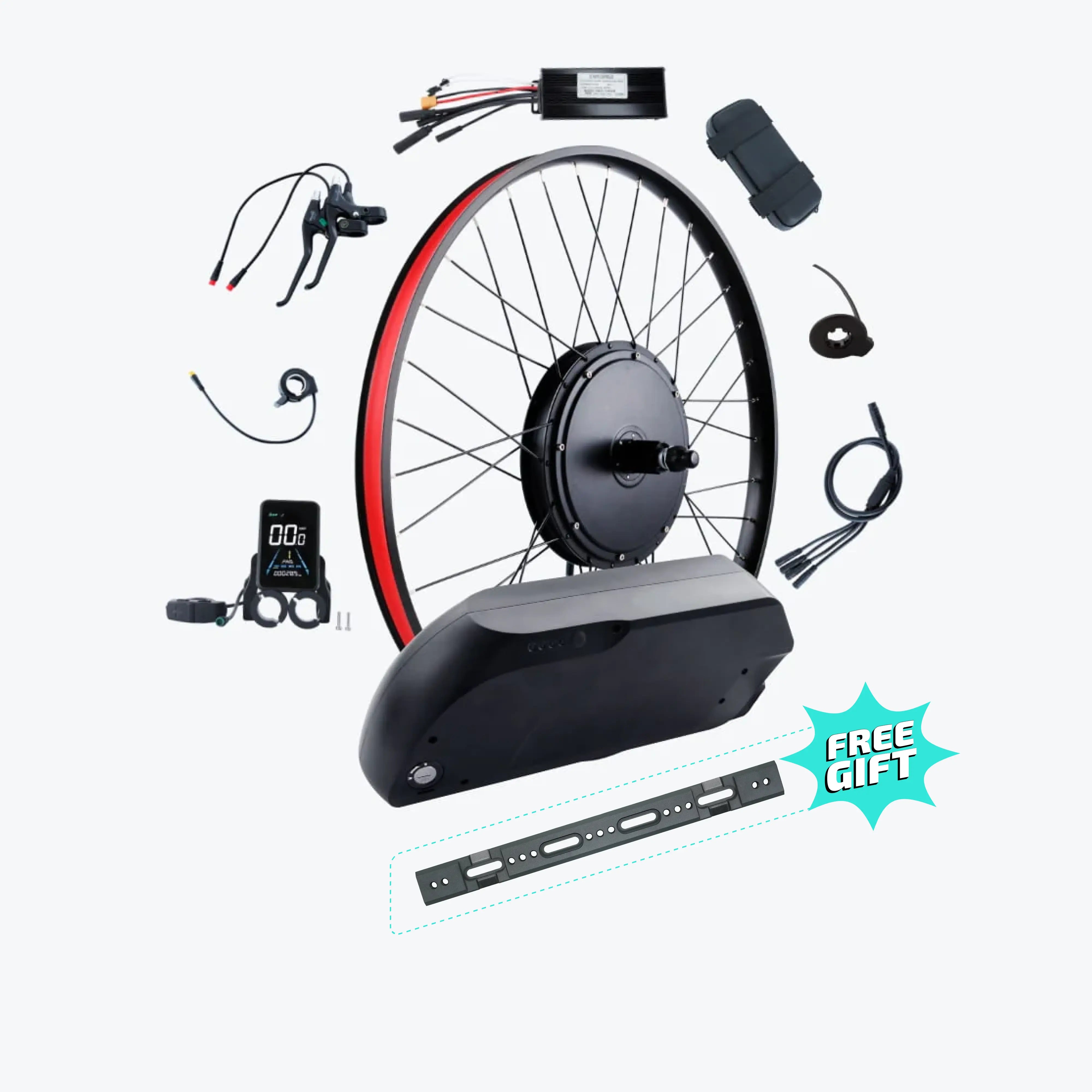

Most modern displays accommodate both voltage ranges, but verify compatibility before purchasing. Brake sensors, throttles, and PAS sensors generally work across voltage ranges, though some require voltage-specific versions.

When 52V is the Right Choice

Choose a 52V system when you need:

- Urban commuting: Speeds of 30-40 mph handle city traffic perfectly

- Trail riding: Adequate power for moderate off-road terrain

- Longer range: Better efficiency extends distance per charge

- Legal compliance: Easier to find power levels within legal limits

- Cost efficiency: Lower initial investment and operating costs

- Lighter weight: Reduced system weight improves handling

The 52V ebike battery collection offers multiple capacity options to match your specific range requirements without over-investing in unnecessary power.

When 72V Makes Sense

Opt for a 72V system when you require:

- Extreme speeds: Applications demanding 50+ mph capability

- Steep terrain: Mountainous areas with sustained long climbs

- Heavy loads: Cargo hauling or towing applications

- Off-road racing: Competitive applications where power matters

- Maximum acceleration: Situations requiring instant power delivery

- Professional use: Commercial applications justifying the investment

The 72V ebike battery systems deliver uncompromising performance for riders who genuinely need maximum power.

Installation and Technical Considerations

Both systems require similar installation processes, though 72V demands extra attention to electrical safety:

Wire gauge requirements: 72V systems need heavier gauge wire (10-12 AWG minimum) compared to 52V (12-14 AWG)

Connector ratings: All connectors must handle continuous amperage without overheating—60A+ for 72V, 40A+ for 52V

Torque arms: Essential for both systems, but 72V motors generate forces requiring reinforced mounting

Cable management: Critical for preventing electrical faults, especially with higher-voltage systems

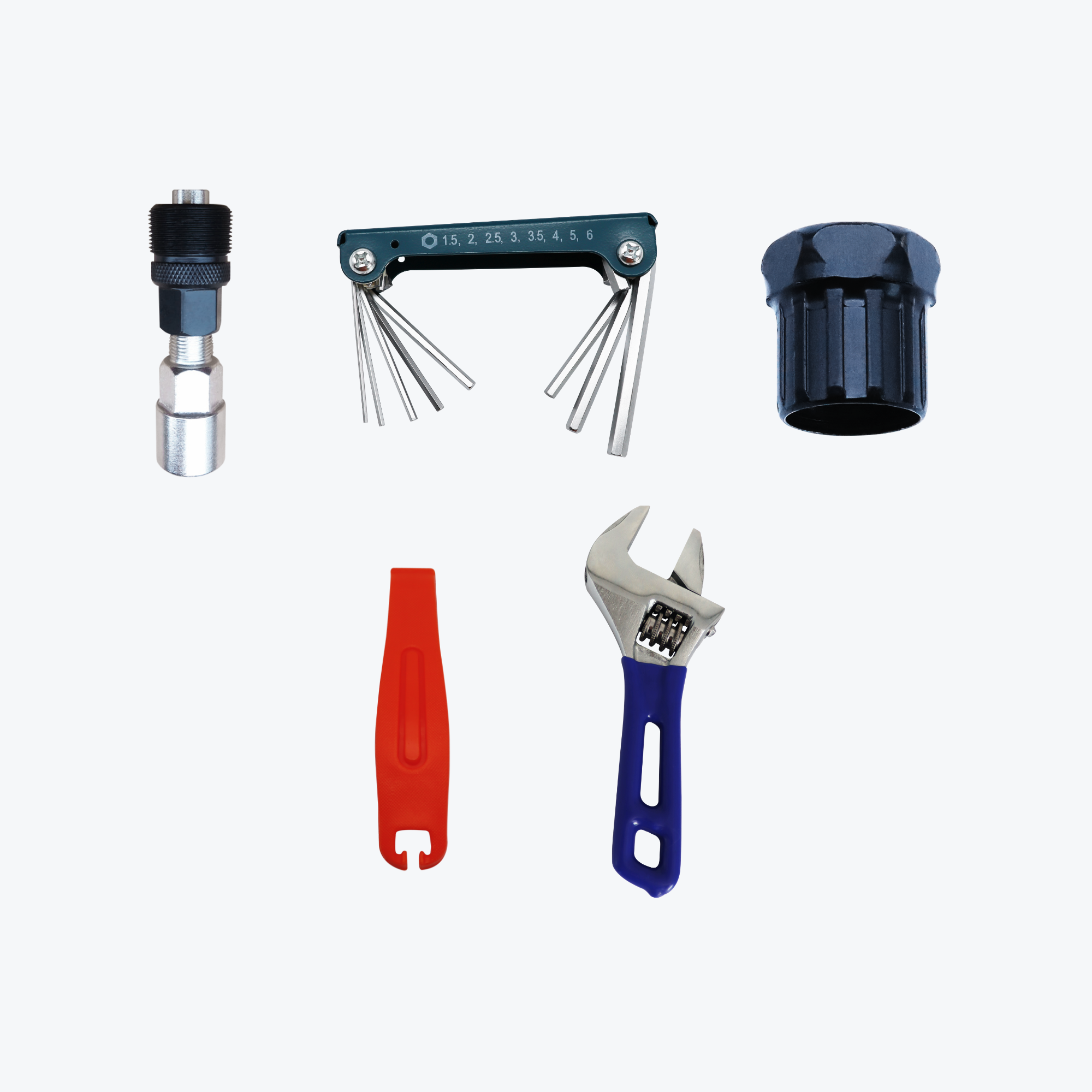

Most riders can install either system within 2-3 hours using basic tools, though professional installation ensures optimal performance and safety.

Making Your Decision: A Practical Framework

Consider these questions:

- What's your typical riding terrain? Flat to moderate hills favor 52V; extreme terrain may justify 72V

- What speeds do you actually need? 30-40 mph (52V) suffices for most; 50+ mph (72V) serves specific applications

- How important is range? Better efficiency makes 52V superior for distance

- What's your budget? 52V delivers better value for most riders

- Where will you ride legally? Check local regulations before investing in high-power systems

For 90% of e-bike conversions, 52V systems provide the optimal balance of performance, efficiency, cost, and practicality. The remaining 10% of riders with extreme requirements will appreciate what 72V delivers—but only if they genuinely need that capability.

Frequently Asked Questions

Can I upgrade from 52V to 72V later?

No, voltage systems aren't interchangeable. Upgrading requires replacing the motor, controller, battery, and potentially the display—essentially a complete new system.

How much faster is 72V compared to 52V?

Approximately 15-25 mph faster in practical terms. 52V systems typically reach 30-37 mph, while 72V systems achieve 47-53 mph depending on motor power and gearing.

Do 72V systems really drain batteries faster?

Yes, higher power output inherently consumes more energy. Under identical riding conditions, 72V systems typically achieve 10-20% less range than comparable 52V systems.

Which voltage is better for hill climbing?

72V provides superior climbing power for extremely steep or long grades, but 52V handles most hills adequately with proper gearing and reasonable rider effort.

Are 52V batteries more reliable than 72V?

Generally yes, due to lower electrical stress per cell. 52V configurations typically achieve 1000+ cycles, while 72V systems may see 800-1000 cycles under similar usage patterns.

Can I use a 72V battery on a 52V motor?

Absolutely not. Applying 72V to a 52V-rated motor will immediately damage or destroy the motor and controller. Always match voltage exactly.

Which system requires less maintenance?

52V systems typically require less frequent maintenance due to lower operating temperatures and reduced mechanical stress on components.

Conclusion

The 52V vs 72V decision ultimately depends on honest assessment of your actual needs. Most riders discover that 52V conversion kits deliver everything they want—excellent speed, strong climbing ability, practical range, and reasonable cost—without the complications of ultra-high voltage.

Reserve 72V for situations that genuinely demand extreme performance. If you're unsure, start with 52V. You'll likely find it more than adequate, and if you later discover you need more power, you'll have gained valuable experience understanding exactly what that additional capability should deliver.