Mid-drive conversion kits deliver superior hill-climbing capability, exceptional efficiency, and natural pedaling dynamics that hub motors cannot match—making them the optimal choice for challenging terrain, technical trails, and riders prioritizing performance over installation simplicity.

While the best ebike kit options include both hub and mid-drive systems, understanding when mid-drive advantages justify the additional installation complexity and modest cost premium determines whether this motor type serves your specific riding needs.

This comprehensive guide examines top mid-drive conversion kits, their unique benefits for demanding applications, installation considerations, and selection criteria helping you choose the perfect system for conquering hills and dominating off-road adventures.

Why Mid-Drive Motors Excel for Hills and Off-Road

Understanding the fundamental mechanical advantages mid-drive systems provide explains their dominance in demanding terrain applications where hub motors struggle.

Core Mid-Drive Advantages

Gear Leverage Multiplication:

Mid-drive motors power the cranks rather than the wheel, allowing the motor to utilize the bicycle's existing gear system:

Mechanical Advantage:

- Motor output multiplied by gear ratios

- Low gears provide massive torque to rear wheel

- High gears enable efficient cruising

- Same motor delivers varied performance

- Optimal power for any situation

Real-World Hill Climbing:

- 500W mid-drive in low gear = effective 1500W+ to wheel

- 750W mid-drive conquers grades hub motors cannot

- Sustained climbing without overheating

- Efficient power delivery

- Battery range preserved

Technical Trail Navigation:

- Torque available at low speeds

- Controlled power for obstacles

- Natural bike handling maintained

- Weight centralized for balance

- Professional MTB feel

Weight Distribution Benefits

Central Mounting Advantages:

Mid-drive motors mount at the bottom bracket (bike's center):

Handling Improvements:

- Weight at lowest point (stability)

- Centered mass (neutral handling)

- No wheel weight (responsive steering)

- Maintains bike geometry

- Professional feel preserved

Off-Road Benefits:

- Better suspension performance

- Improved traction both wheels

- Easier obstacle navigation

- Natural bike behavior

- Technical riding capability

Efficiency Advantages

Energy Optimization:

Mid-drives achieve superior efficiency through mechanical advantage:

Range Benefits:

- 20-30% better efficiency than equivalent hub motor

- Extended range from same battery

- Less battery weight needed

- Lower operating temperatures

- Reduced component stress

Climbing Efficiency:

- Motor operates at optimal RPM in appropriate gear

- Hub motors struggle at low speeds (inefficient)

- Battery capacity utilized effectively

- Heat generation minimized

- Consistent performance maintained

Top Mid-Drive Conversion Kit: Tongsheng TSDZ8 System

The mid motor electric conversion kit represents the optimal mid-drive choice for most riders requiring hill-climbing capability and off-road performance.

Complete System Specifications

Motor Configuration:

Tongsheng TSDZ8 Details:

- Brand: Tongsheng (established manufacturer)

- Power Options: 36V 500W or 48V 750W

- Maximum Torque: 140Nm (exceptional)

- Motor Weight: 4.8kg (compact and light)

- Construction: Sealed bearing system

- Durability: Professional-grade components

- Reliability: Proven track record

Why Tongsheng Excels:

- Integrated torque sensor (responsive feel)

- Compact 4.8kg weight

- Proven reliability across thousands of installations

- Affordable compared to premium brands

- Comprehensive support and parts availability

- Direct Bafang competition with advantages

Performance Capabilities:

Power Delivery:

- 500W: Ideal for technical trails, efficiency priority

- 750W: Serious hill-climbing, loaded touring

- 140Nm torque: Exceptional low-speed pulling power

- Smooth power curve: Natural pedaling feel

- Torque sensor: Responsive to pedaling effort

Speed and Range:

- Speed: 30-50 km/h (depending on gearing and power)

- Range: 40-60km typical usage

- Efficiency: Superior to hub motors

- Climbing: Conquers 15-20% grades confidently

- Load Capacity: Handles cargo and heavy riders

Battery Options and Configuration

Available Capacities:

36V System (500W Motor):

- Battery: 36V 16Ah LG cells

- Range: 40-50km typical terrain

- Weight: Moderate

- Application: Technical trail riding, efficiency focus

- Climbing: Excellent with gear leverage

48V System (750W Motor):

- Battery: 48V 16Ah LG cells

- Range: 40-60km mixed terrain

- Weight: Slightly heavier

- Application: Serious climbing, loaded touring

- Climbing: Exceptional power for steep grades

Battery Quality:

- Cells: LG branded (premium quality)

- BMS: Integrated protection system

- Cycles: 1000+ recharge capability

- Waterproof: IP66 rating

- Mounting: Down tube bottle cage holes

- Lock: Integrated security feature

Complete Kit Includes

Comprehensive Package:

Motor Components:

- Tongsheng TSDZ8 motor unit

- 38T aluminum chainring

- Motor mounting hardware

- Bottom bracket tool (included)

- Protective motor guard

- Comprehensive installation manual

Electrical System:

- Professional display with comprehensive data

- Torque sensor (integrated in motor)

- Brake cut-off levers (both front and rear)

- Throttle option (if desired)

- Speed sensor

- Complete wiring harness

Battery System:

- LG cell battery pack (36V or 48V)

- Battery mounting bracket

- 2A charger (8-10 hour charge)

- Battery lock and keys

- Charging cable

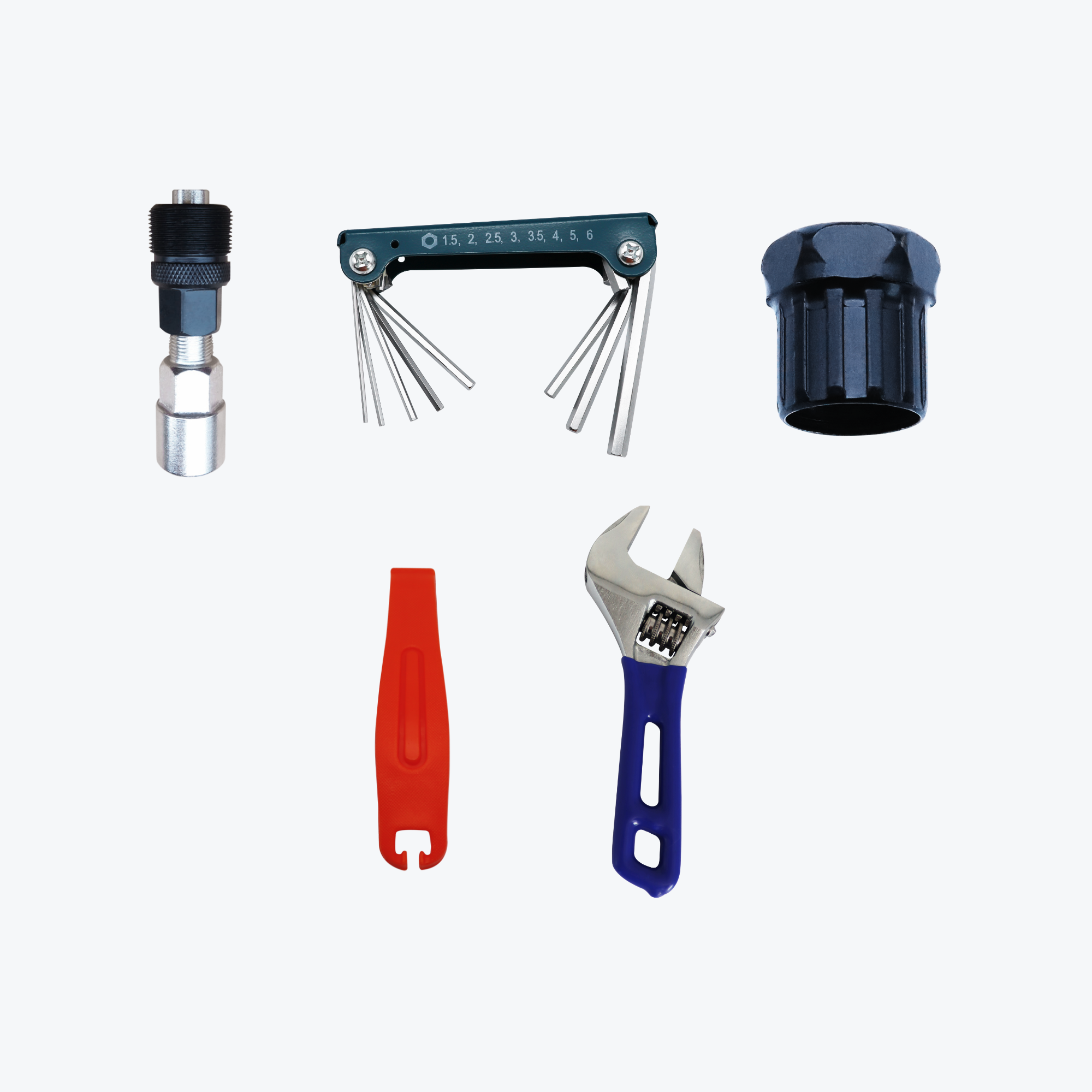

Installation Accessories:

- Bottom bracket removal tool

- Crank puller tool

- All mounting hardware

- Cable ties for wire management

- Installation instructions

- Video tutorial access

Mid-Drive vs Hub Motor Comparison

Performance Differences

|

Performance Factor |

Mid-Drive (500-750W) |

Hub Motor (1000W) |

Winner |

|

Steep Hill Climbing |

Excellent (gear leverage) |

Good (raw power) |

Mid-Drive |

|

Sustained Climbing |

Superior (efficient) |

Adequate (heats up) |

Mid-Drive |

|

Technical Trails |

Excellent (torque at low speed) |

Poor (inefficient low speed) |

Mid-Drive |

|

Flat Speed |

Good (gear dependent) |

Excellent (direct drive) |

Hub Motor |

|

Efficiency |

Superior (20-30% better) |

Good |

Mid-Drive |

|

Range |

Better (more efficient) |

Good |

Mid-Drive |

|

Natural Feel |

Excellent (torque sensor) |

Good (power assist) |

Mid-Drive |

|

Weight Distribution |

Optimal (centered) |

Front/Rear heavy |

Mid-Drive |

|

Installation Complexity |

Moderate (30-40 min) |

Simple (20 min) |

Hub Motor |

|

Maintenance |

Moderate (chain wear) |

Minimal |

Hub Motor |

|

Cost |

Moderate |

Lower |

Hub Motor |

When Mid-Drive Excels

Optimal Applications:

Mountain Bike Trail Riding:

- Technical climbing required

- Low-speed torque essential

- Weight distribution critical

- Natural handling mandatory

- Professional feel desired

Steep Terrain Commuting:

- Sustained 10-15%+ grades

- Multiple steep climbs

- Efficiency priority

- Extended battery life needed

- Consistent performance required

Loaded Touring:

- Heavy cargo carried

- Steep passes encountered

- Range maximization critical

- Gear leverage beneficial

- Long-term reliability essential

Performance Focus:

- Natural pedaling feel priority

- Responsive power delivery

- Efficient operation valued

- Quality construction appreciated

- Upgrade from hub motor

When Hub Motor Better Choice

Hub Motor Advantages:

Simple Urban Commuting:

- Flat to moderate terrain

- Simplicity priority

- 20-minute installation wanted

- Minimal maintenance desired

- Lower cost important

Speed Priority:

- Flat terrain riding

- Maximum speed focus

- Direct power delivery

- Less complexity valued

- Straightforward operation

First Conversion:

- Learning experience

- Minimal tools available

- Simple installation critical

- Hub motor adequate

- Future mid-drive possible

Mid-Drive Installation Considerations

Installation Complexity Reality

Time and Skill Requirements:

Installation Steps:

- Remove existing cranks (crank puller tool)

- Remove bottom bracket (BB tool)

- Install motor unit in BB shell

- Install motor chainring

- Reinstall cranks or use provided ones

- Install battery and mount

- Connect all electrical components

- Route and secure cables

- Test all functions

- Adjust and configure

Realistic Timeline:

- First-time installer: 60-90 minutes

- Experienced mechanic: 30-40 minutes

- Following video tutorial: Straightforward

- With proper tools: No major difficulties

Tools and Preparation

Essential Tools Provided:

Included in Kit:

- Bottom bracket removal tool

- Crank puller tool (if needed)

- Motor mounting hardware

- All fasteners and brackets

- Cable management supplies

Common Installation Challenges

Challenge 1: Bottom Bracket Removal

Issue: Seized bottom bracket difficult to remove

Solutions:

- Apply penetrating oil 24 hours before

- Use proper BB removal tool

- Apply heat carefully if necessary

- Seek professional BB removal if stuck

- Replace with included components

Challenge 2: Chain Length

Issue: Original chain may be too short for mid-drive

Solutions:

- Measure required length carefully

- Purchase new chain if needed (inexpensive)

- Use chain breaker tool properly

- Follow manufacturer specifications

- Test shifting across all gears

Challenge 3: Cable Routing

Issue: Multiple cables require clean routing

Solutions:

- Plan routing before securing

- Use provided cable ties systematically

- Follow frame natural lines

- Allow handlebar turning clearance

- Secure every 15-20cm

Challenge 4: Motor Alignment

Issue: Chainring alignment critical for shifting

Solutions:

- Follow alignment specifications precisely

- Check chainline with straightedge

- Adjust spacers if provided

- Test shifting thoroughly

- Fine-tune before securing

Maximizing Mid-Drive Performance

Efficiency Maximization:

- Use appropriate gear for terrain

- Keep motor in efficient RPM range

- Anticipate terrain changes

- Shift proactively not reactively

- Monitor battery consumption

Technical Trail Navigation:

- Low gear for obstacles

- Torque available at low speed

- Controlled power application

- Balance and traction maintained

- Professional technique applicable

Maintenance Specific to Mid-Drive

Mid-Drive Selection Decision Framework

Choose Mid-Drive System If:

Terrain Requirements: ✓ Regular climbing of 10%+ grades ✓ Sustained steep sections ✓ Technical trail riding ✓ Off-road mountain biking ✓ Loaded touring with hills ✓ Variable terrain constantly

Performance Priorities: ✓ Natural pedaling feel important ✓ Efficiency valued highly ✓ Range maximization critical ✓ Professional bike handling desired ✓ Quality construction appreciated ✓ Long-term investment perspective

Rider Characteristics: ✓ Mechanically comfortable ✓ 30-40 minute installation acceptable ✓ Willing to learn installation ✓ Appreciates quality engineering ✓ Performance focus ✓ Upgrade from hub motor

Real-World Mid-Drive Success

Mountain Bike Trail Conversion

Rider Profile:

- Technical trail riding enthusiast

- Steep climbs frequently encountered

- Performance and feel priority

- Mechanical skills adequate

System Selected:

- 48V 750W Tongsheng TSDZ8

- 48V 16Ah LG battery

Key Lessons: Mid-drive transformation enables trail riding previously impossible, with natural feel, exceptional climbing, and efficiency justifying modest installation complexity and investment premium.

Hilly Commute Solution

Rider Profile:

- 15km commute each way

- 12% grade climb mid-route

- Previously exhausted arriving at work

- Wanted reliable daily transportation

System Selected:

- 36V 500W Tongsheng TSDZ8

- 36V 16Ah battery

- Professional installation

Results After 12 Months:

- Climbs effortlessly in low gear

- Arrives fresh every day

- 60-70km range (2 days commuting)

- Zero mechanical issues

- Life-changing experience

- Perfect solution achieved

Key Lessons: Mid-drive with appropriate gearing handles serious commute hills efficiently, delivering reliable daily transportation while preserving battery range through superior efficiency.

Conclusion

Mid-drive conversion kits represent the optimal choice for riders facing regular significant climbing, technical trail riding, or prioritizing efficiency, natural feel, and professional handling over installation simplicity. The electric bike kit battery systems with Tongsheng TSDZ8 mid-drive motors deliver exceptional 140Nm torque, gear leverage advantages, and centered weight distribution that hub motors cannot match for demanding terrain applications.

The 500W configuration serves technical trail riders and efficiency-focused users perfectly, while the 750W version conquers the steepest grades and handles loaded touring confidently. The 30-40 minute installation, while more complex than hub motors, remains achievable for mechanically comfortable riders following comprehensive instructions—with rewards of superior performance justifying the modest additional effort.

Ready to conquer hills and dominate trails with mid-drive advantages? Explore the complete ebike kit battery range including professional mid-drive systems with detailed specifications, installation guidance, and expert support ensuring your conversion delivers the exceptional climbing capability and natural performance only mid-drive motors provide.

Frequently Asked Questions

Why are mid-drive conversion kits better for hills than hub motors?

Mid-drives utilize the bicycle's existing gears, multiplying motor torque through mechanical advantage: 500W mid-drive in low gear delivers equivalent wheel power of 1500W+ hub motor, while maintaining efficiency and preventing overheating.

Is the Tongsheng TSDZ8 mid-drive kit difficult to install?

Installation requires removing bottom bracket and cranks (30-40 minutes typical), needing basic mechanical comfort and included tools. First-time installers complete successful installations following comprehensive video tutorials and instructions.

What's the maximum hill grade a 500W or 750W mid-drive can climb?

500W mid-drive conquers 12-15% sustained grades confidently with appropriate gearing, while 750W handles 15-20% grades and extreme terrain.

Do mid-drive motors wear out bicycle chains and gears faster?

Yes, mid-drives increase drivetrain wear 50-100% over non-electric bikes because motor torque transmits through chain. However, regular chain maintenance (monthly inspection, replacement at 0.

How does mid-drive efficiency compare to hub motors for range?

Mid-drives achieve 20-30% better efficiency than equivalent hub motors through optimal motor RPM operation via gears, especially when climbing or varying terrain.