Converting your trusty old bicycle into an electric powerhouse sounds exciting, but is your vintage frame up to the challenge? Before you install that e-bike conversion kit, understanding frame compatibility and safety considerations could save you from costly mistakes—or worse, accidents.

Understanding Frame Strength Fundamentals

The structural integrity of your bicycle frame determines whether it can safely handle the additional stresses of motorized assistance. Unlike purpose-built e-bikes, older bicycles weren't designed with electric motors in mind, making frame assessment absolutely critical.

Key Frame Stress Points

When you add a motor to your bike, several areas experience increased loading:

- Dropout areas (where wheels attach) bear motor torque

- Bottom bracket endures mid-drive motor forces

- Fork crown handles front hub motor stress

- Downtube supports battery weight

- Chainstay transfers power from mid-drive systems

Material Matters: Which Frames Handle Conversion Best?

Not all bicycle materials respond equally to e-bike conversion demands.

Steel Frames Steel offers excellent fatigue resistance and typically handles conversion well. The material's flexibility absorbs shock while maintaining structural integrity. Older steel frames, particularly those from quality manufacturers, often prove surprisingly robust for conversion projects.

Aluminum Frames Aluminum presents a mixed picture. Modern aluminum frames with reinforced dropout areas generally work well, but older or lightweight aluminum frames may develop stress cracks. The material doesn't flex like steel—it fatigues. Pay particular attention to weld points and dropout thickness.

Carbon Fiber Frames Exercise extreme caution here. Carbon fiber excels at directional loads but wasn't designed for the torque patterns e-bike motors create. Most manufacturers void warranties when motors are added. Unless specifically rated for e-bike use, avoid converting carbon frames.

Chromoly and High-Tensile Steel Chromoly (chromium-molybdenum steel) handles conversion exceptionally well due to superior strength-to-weight ratios. High-tensile steel works adequately for lower-power conversions but may flex excessively under high torque applications.

Power Level Considerations for Older Frames

Your frame's age and condition should dictate appropriate motor power selection.

|

Frame Age |

Recommended Maximum Power |

Best Kit Type |

|

0-5 years (good condition) |

Up to 2000W |

Hub or mid-drive |

|

5-10 years (well-maintained) |

Up to 1000W |

Hub motor preferred |

|

10-15 years (regular use) |

Up to 750W |

Front hub or lower-power mid-drive |

|

15+ years (vintage) |

Up to 500W |

Front hub only |

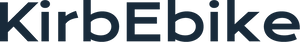

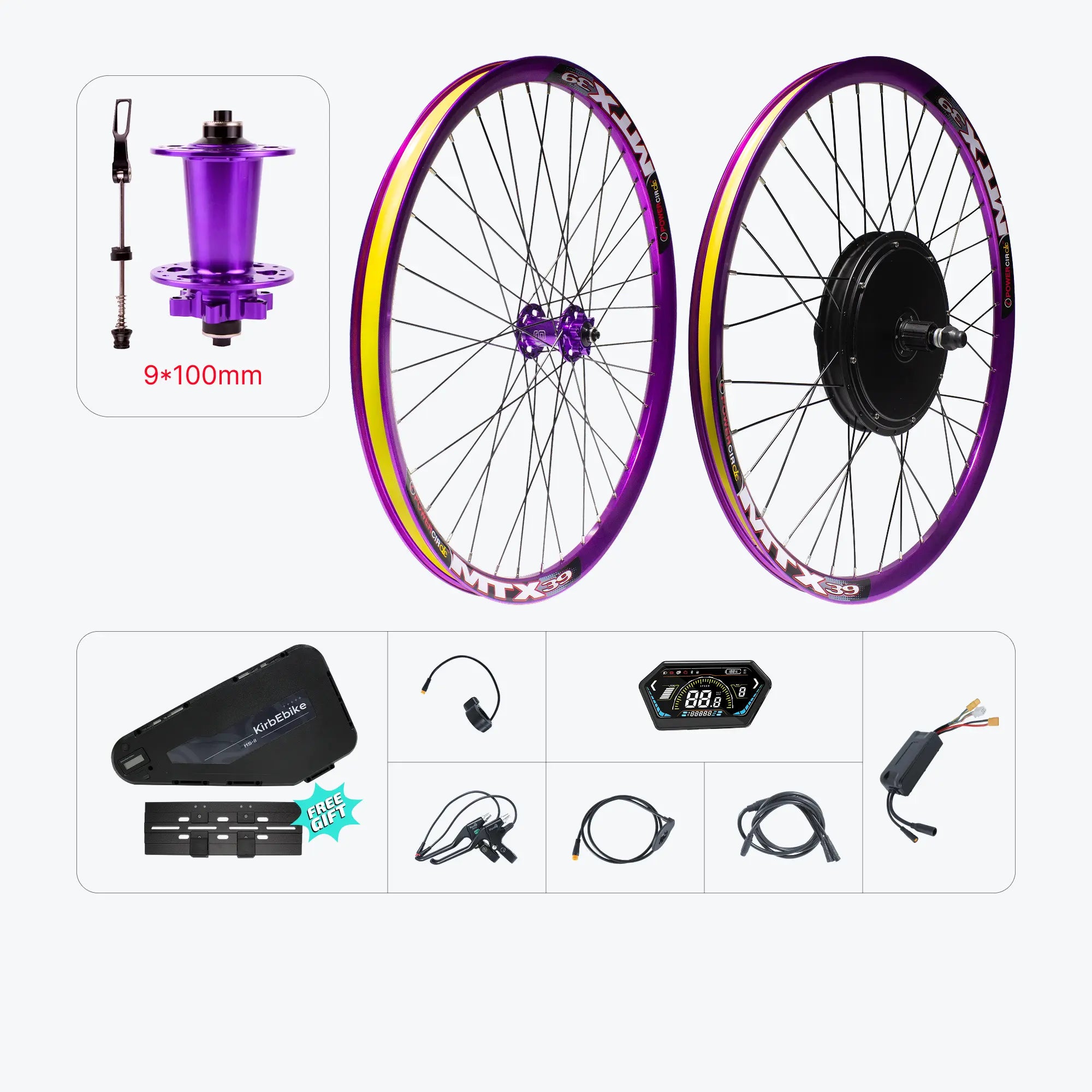

Starting with a lower-power system like KirbEbike's 500W conversion kits allows you to test your frame's response before committing to higher outputs.

Hub Motor vs. Mid-Drive: Safety Implications for Older Frames

Hub Motor Systems Hub motors distribute stress directly to the dropout area. Front hub motors place stress on fork dropouts, typically the strongest part of older frames. Rear hub motors stress the rear triangle but bypass the drivetrain entirely, reducing wear on older chains and cassettes.

Mid-Drive Systems Mid-drive motors like the Tongsheng TSDZ8 system multiply torque through your bike's gears, placing significant stress on the bottom bracket, chain, and cassette. While offering superior hill-climbing ability, they demand frames in excellent condition and may require drivetrain upgrades.

Pre-Conversion Frame Assessment Checklist

Before purchasing any conversion kit, conduct this thorough inspection:

Visual Inspection

- Check for rust, especially at joints and welds

- Examine paint for stress cracks (fine lines radiating from joints)

- Look for dents, particularly on downtubes and chainstays

- Inspect dropout alignment using a straight edge

Structural Tests

- Apply pressure to test bottom bracket play

- Check headset tightness and fork alignment

- Bounce the bike to listen for creaks or unusual sounds

- Examine wheel true and spoke tension

Measurement Verification

- Confirm dropout width (typically 100mm front, 135mm rear)

- Measure bottom bracket shell width for mid-drive compatibility

- Check frame clearance for battery mounting

- Verify fork dropout spacing for front hub motors

Common Risk Factors with Older Frames

Several red flags should pause your conversion plans:

Fatigue Cracks Hairline cracks near welds or stress points indicate metal fatigue. These will only worsen under motor power and pose serious safety risks.

Corrosion Damage Surface rust might seem cosmetic, but internal corrosion weakens structural integrity. Aluminum oxide (white powder) on aluminum frames indicates corrosion that compromises strength.

Previous Damage Bikes that survived crashes may have hidden damage. Even if straightened, aluminum and carbon fiber don't recover original strength.

Modification History Previous modifications—particularly welded-on accessories or drilled holes—create stress concentration points that may fail under increased loads.

Enhancing Frame Safety for Conversion

If your frame passes basic assessment but you have concerns, several reinforcement strategies exist:

Torque Arms Essential for hub motor installations, torque arms prevent motor rotation from damaging dropouts. Older frames with thinner dropout material particularly benefit from dual torque arms.

Dropout Reinforcement Steel reinforcement plates can be fabricated or purchased to distribute hub motor torque across larger frame areas. This simple modification dramatically increases older frame safety margins.

Frame Bracing For extremely high-power applications, custom frame bracing can be added by experienced frame builders. This involves welding or brazing additional material to strengthen critical areas.

Battery Mounting Safety for Older Frames

Battery placement affects handling and structural safety. The various battery options from KirbEbike require different mounting approaches.

Downtube Mounting Most common and stable, but requires adequate bosses or mounting points. Older frames may lack threaded inserts, necessitating clamping systems that could damage paint or thin tubing.

Rear Rack Mounting Distributes weight over the rear wheel, but older rack mounts may not handle heavier lithium batteries. Verify rack mount reinforcement and consider upgraded racks rated for e-bike batteries.

Frame Bag Mounting Flexible option for oddly-shaped vintage frames, but ensure the mounting system doesn't create pressure points that could damage tubing.

Real-World Testing Protocol

Once installed, gradually test your converted bike:

- Initial short rides (under 5km) at low assist levels

- Inspect after each ride for unusual sounds, vibrations, or visible changes

- Progressively increase power levels and ride distances

- Monitor temperature of motor and battery mounts

- Regularly retorque all fasteners during the first 100km

When Professional Assessment Makes Sense

Consider professional frame evaluation if:

- Your bike has sentimental or financial value

- The frame shows any questionable condition

- You're planning high-power conversion (1500W+)

- The frame is aluminum and over 10 years old

- You lack mechanical experience for proper assessment

Frame builders, quality bike shops, and even some e-bike specialty stores offer structural assessment services. The modest cost often prevents expensive mistakes.

Legal and Insurance Considerations

Frame safety intersects with legal responsibility. In many jurisdictions, converted e-bikes must meet safety standards. A frame failure resulting in injury could raise liability questions, particularly if the conversion exceeded reasonable safety margins.

Some homeowner's insurance policies cover bicycle liability, but conversion might void coverage. Check your policy before conversion, and consider specialized e-bike insurance for high-power systems.

Long-Term Maintenance for Converted Frames

Ongoing inspection becomes crucial post-conversion:

Monthly Checks

- Dropout area inspection for stress cracks

- Fastener tightness verification

- Battery mount security

- Spoke tension and wheel true

Quarterly Maintenance

- Thorough frame cleaning to reveal potential cracks

- Bottom bracket inspection and servicing

- Drivetrain component assessment

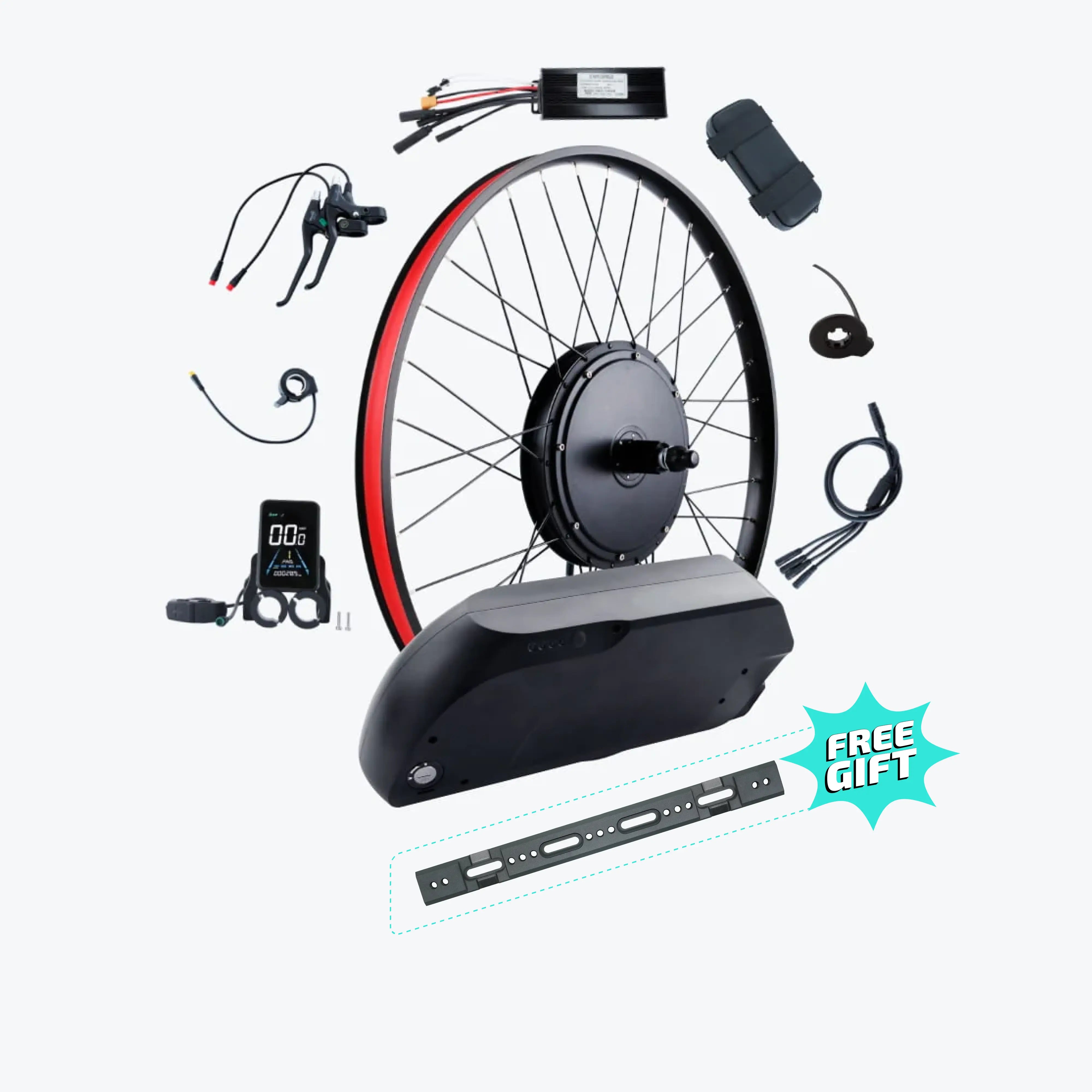

- Brake system verification (motors increase braking demands)

Annual Service Consider professional inspection annually, particularly for aluminum frames or high-power systems. Many issues develop slowly and become visible only with experienced eyes.

Making the Safe Choice

Ultimately, frame safety for e-bike conversion depends on honest assessment of your bicycle's condition matched with appropriate conversion power levels. A well-maintained steel frame from your grandfather's era might convert more safely than a poorly-stored aluminum bike from five years ago.

The e-bike conversion kits from KirbEbike offer power options from 250W to 4000W, allowing you to match system power to frame capability. Starting conservative lets you enjoy electric assistance while maintaining safety margins that protect both you and your investment.

Your old bike deserves a second life, but not at the expense of your safety. Take time for proper assessment, choose appropriate components, and don't hesitate to seek professional advice when uncertainty arises. Done correctly, converting that older frame transforms nostalgic cycling into practical modern transportation.

Frequently Asked Questions

Can I convert a 20-year-old mountain bike to an e-bike safely?

Yes, if the steel or chromoly frame shows no cracks, significant rust, or previous damage. Stick with 500-750W hub motors and conduct thorough pre-conversion inspection. Vintage mountain bikes often feature robust frames that handle conversion well.

How do I know if my frame dropouts are strong enough?

Measure dropout thickness (should be at least 3mm for hub motors), check for steel rather than aluminum construction, and look for factory-forged rather than stamped dropouts. Always use torque arms regardless of dropout strength.

Is a front hub motor safer than rear for old frames?

Generally yes, because front forks typically feature stronger dropout construction and the motor stress doesn't affect the rear triangle or drivetrain. Front hub systems also maintain the original rear wheel, preserving factory-tested strength.

What frame material should I absolutely avoid converting?

Non-reinforced carbon fiber frames top the avoid list, followed by extremely lightweight aluminum race frames and any frame showing visible cracks, severe corrosion, or previous crash damage regardless of material.

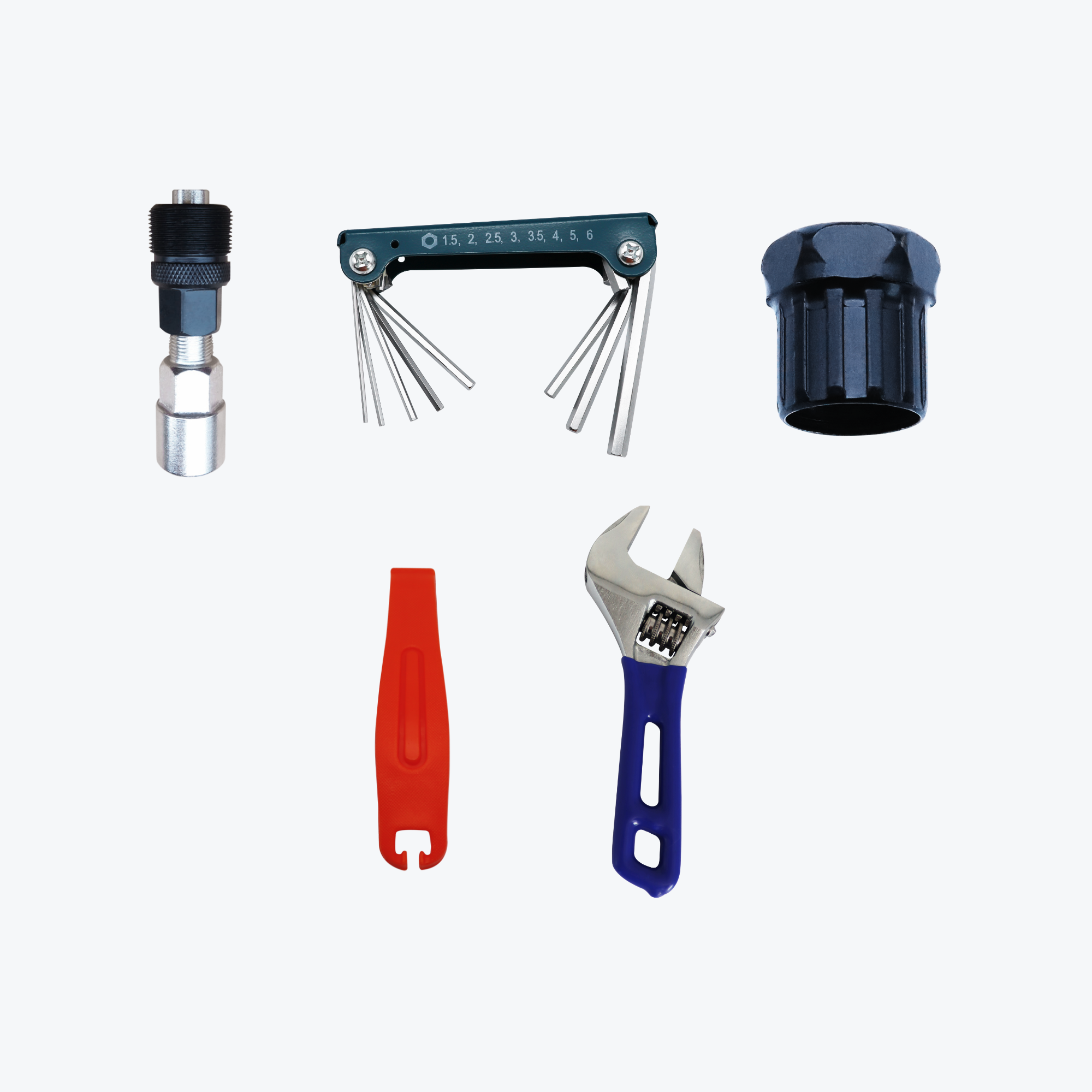

Do I need special tools to assess frame safety?

Basic assessment requires only visual inspection, a straight edge, and careful handling. However, a spoke tension meter, dropout alignment gauge, and potentially ultrasonic testing equipment help for thorough evaluation.

How much weight does a conversion kit add to my frame?

Typical hub motor kits add 4-7kg for the motor and 2-4kg for batteries, totaling 6-11kg. Mid-drive systems add slightly less motor weight but may require heavier batteries. Ensure your frame's maximum weight rating accommodates these additions plus rider weight.

Can I strengthen my frame before conversion?

Yes, through professional welding/brazing of reinforcement plates at stress points, adding torque arms, upgrading to reinforced dropouts, or installing frame braces. Always consult experienced frame builders for modification work.