Rear-wheel conversion kits deliver superior traction, natural bicycle handling, powerful performance, and optimal weight distribution—making them the preferred choice for serious riders, challenging terrain, higher power applications, and anyone prioritizing performance over installation simplicity.

While the best ebike kit options include front, rear, and mid-drive configurations, understanding when rear-wheel advantages justify modest installation complexity determines whether this proven approach serves your specific riding needs and performance expectations.

This comprehensive guide examines top rear-wheel conversion kits, their unique benefits for demanding applications, installation considerations, and selection criteria helping you achieve professional e-bike performance through the most popular motor placement worldwide.

Why Rear-Wheel Conversion Kits Excel for Performance

Understanding the fundamental advantages rear-wheel motor placement provides explains their dominance among performance-focused riders and demanding applications.

Superior Traction Advantages

Weight Distribution Benefits:

Rear-wheel drive concentrates power where natural weight distribution provides maximum traction:

Physics of Traction:

- Rider weight primarily over rear wheel

- Battery weight adds rear traction

- Acceleration shifts weight rearward

- Climbing transfers weight to rear

- Power applied where grip exists

Real-World Traction Benefits:

Dry Conditions:

- Excellent power transfer

- Minimal wheel slip

- Confident acceleration

- Predictable handling

- Professional feel

Wet Conditions:

- Adequate traction maintained

- Better than front-wheel drive

- Smooth power essential

- Quality tires critical

- Rider awareness helpful

Hill Climbing:

- Weight transfers to rear (advantage)

- Traction increases under load

- Powerful acceleration possible

- Steep grades manageable

- Superior to front-wheel

Loose Surfaces:

- Off-road capability excellent

- Gravel roads handled well

- Trail riding capable

- Power when needed

- Confidence-inspiring

Natural Handling Characteristics

Bicycle Feel Preserved:

Rear-wheel motors maintain familiar bicycle handling dynamics:

Steering Precision:

- Front wheel unweighted (responsive)

- Natural steering feel preserved

- Low-speed maneuvering normal

- Parking and storage easy

- Bicycle-like handling

Weight Distribution:

- More natural than front motors

- Lower center of gravity

- Balanced bike feel

- Professional dynamics

- Rider confidence high

Cable Management:

- No steering restriction issues

- Simple cable routing

- No handlebar complications

- Clean front-end appearance

- Professional installation

Top Rear-Wheel Conversion Kits by Application

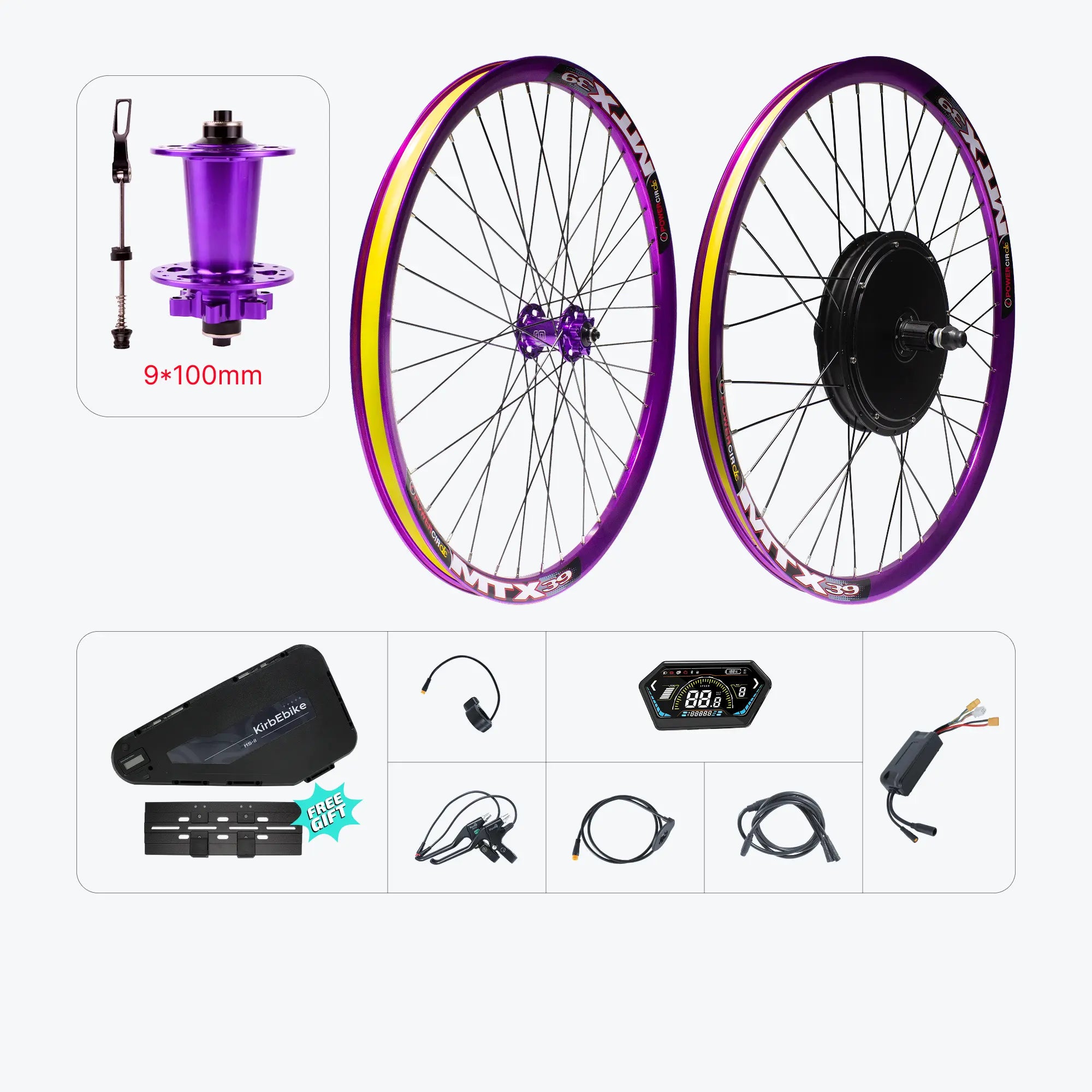

Best All-Around: 48V 1000W System

Why It Excels:

The 48V 1000W rear-wheel configuration represents optimal balance for most riders:

Complete System Specifications:

Motor Details:

- Power: 48V 1000W brushless direct-drive

- Type: Rear hub motor

- Weight: 4-6.2kg depending on rim

- Speed: 45-50 km/h maximum

- Construction: Sealed bearing system

- Waterproofing: IP65 weather resistance

Battery Configuration:

- Capacity: 48V 11.6-16Ah options

- Cells: LG branded (premium quality)

- Range: 35-45km typical terrain

- BMS: Integrated protection

- Mounting: Down tube or rack

- Lock: Integrated security

Performance Capabilities:

- Adequate power for varied terrain

- Hills handled confidently

- 45-50 km/h speeds achieved

- Versatile all-around capability

- Reliable daily transportation

Ideal Applications:

- Daily commuting 10-25km

- Mixed flat and hilly terrain

- Versatile general riding

- First rear-wheel conversion

- Performance on reasonable budget

- Most riders' sweet spot

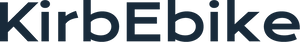

Best High-Performance: 52V 2000W MTX System

Why It Excels:

Serious power for demanding terrain and performance-focused riders:

Complete System Specifications:

Motor Details:

- Power: 52V 2000W brushless direct-drive

- Type: MTX rim rear hub motor

- Weight: 5.1-5.3kg

- Speed: 50-60 km/h capability

- Torque: Exceptional low-end

- Brand: SHENGYI or equivalent quality

Battery Configuration:

- Capacity: 52V 20-30Ah options

- Cells: LG 21700 high-discharge

- Range: 40-60km (20Ah), 50-80km (30Ah)

- Voltage: Superior under load

- Performance: Sustained power delivery

- Quality: Premium construction

Performance Capabilities:

- Serious hill-climbing power

- High-speed cruising sustained

- Heavy load capability

- Quick acceleration

- Professional performance

Ideal Applications:

- Steep terrain commuting

- Mountain bike conversions

- Performance enthusiasts

- Cargo and utility bikes

- Long-distance touring

- Power priority riders

Best Extreme Power: 72V 4000W System

Why It Excels:

Ultimate performance for maximum capability and extreme applications:

Complete System Specifications:

Motor Details:

- Power: 72V 4000W brushless direct-drive

- Type: Heavy-duty rear hub

- Weight: 6.8kg robust construction

- Speed: 75-85+ km/h maximum

- Torque: Unstoppable climbing

- Durability: Professional-grade

Battery Configuration:

- Capacity: 72V 20Ah with 5A fast charger

- Cells: Premium high-discharge

- Range: 40-80km depending on usage

- Voltage: Efficiency at extreme power

- Performance: Motorcycle-like

- Construction: Military-grade

Performance Capabilities:

- Maximum speed capability

- Extreme climbing power

- Professional delivery services

- Ultimate performance

- Unmatched acceleration

Ideal Applications:

- Extreme mountain biking

- Fat tire bike conversions

- Professional delivery

- Maximum performance priority

- Experienced power users

- Ultimate capability desired

Rear-Wheel Installation Process

Installation Complexity Reality

Time and Skill Requirements:

Rear-wheel installation requires modest additional steps versus front:

Complete Installation Steps:

Phase 1: Wheel Removal and Preparation (10 minutes)

- Remove rear wheel

- Transfer cassette to motor wheel (5 minutes)

- Adjust chain if necessary

- Prepare motor wheel

- Check brake compatibility

Phase 2: Motor Wheel Installation (10 minutes)

- Install torque arm(s) if required (750W+)

- Insert motor wheel in dropouts

- Secure axle properly

- Verify wheel centering

- Check brake alignment

- Adjust derailleur

Phase 3: Battery and Components (10 minutes)

- Mount battery to frame

- Install display on handlebars

- Install brake sensors

- Attach pedal assist sensor

- Mount throttle if using

Phase 4: Electrical Connections (5 minutes)

- Connect motor to controller

- Connect battery

- Connect all sensors

- Cable management

- Test all functions

Total Installation Time: 25-35 minutes typical

Skill Level Assessment:

Recommended Experience:

- Comfortable changing bicycle tires

- Used cassette removal tool before

- Understands derailleur adjustment

- Follows detailed instructions

- Patient methodical approach

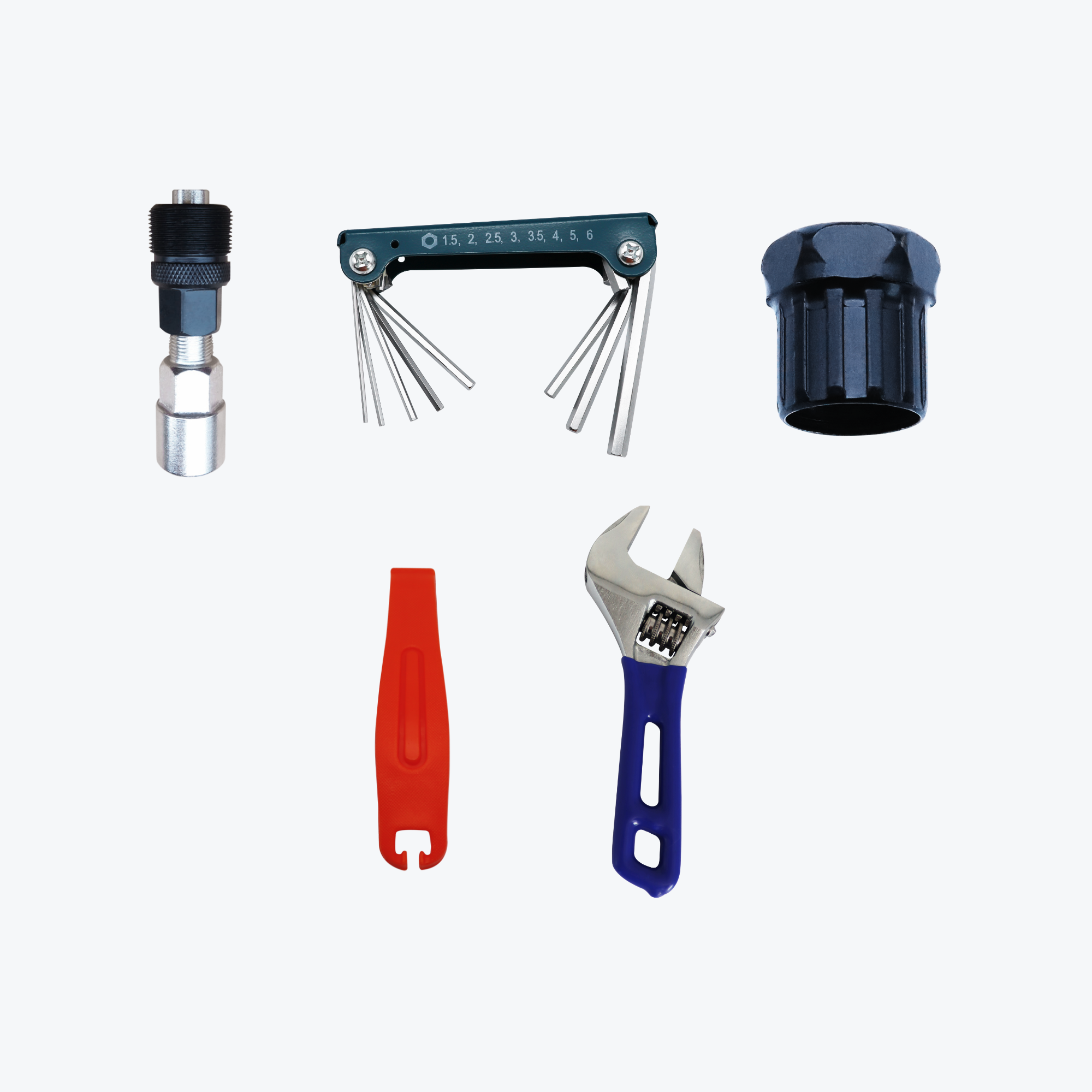

Tools Required:

- Cassette removal tool (included typically)

- Chain whip (included typically)

- Allen key set

- Adjustable wrench

- Torque wrench (recommended)

Torque Arm Requirements

Critical Safety Component:

Torque arms prevent motor axle rotation and dropout damage:

Torque Arm Requirements by Power:

250-500W Systems:

- Torque arm: Recommended but optional

- Steel frames: Often adequate without

- Aluminum frames: Strongly recommended

- Safety margin: Good practice

750-1500W Systems:

- Torque arm: One side minimum required

- Aluminum frames: Absolutely mandatory

- Both sides: Recommended for reliability

- Frame protection: Critical

2000W+ Systems:

- Torque arms: Both sides absolutely required

- Heavy-duty type: Essential

- Proper installation: Non-negotiable

- Frame inspection: Regular checks mandatory

Installation:

- Secure to frame dropout

- Proper bolt torque critical (15-20 Nm)

- Verify tightness periodically

- No movement allowed

Rear vs Front Wheel Comparison

Performance Differences Table

|

Performance Factor |

Rear-Wheel |

Front-Wheel |

Winner |

|

Traction (All Conditions) |

Excellent |

Good (dry), Reduced (wet) |

Rear |

|

Hill Climbing Capability |

Superior |

Adequate |

Rear |

|

Maximum Power Handling |

250-4000W |

250-500W |

Rear |

|

Natural Handling |

Excellent |

Front-heavy |

Rear |

|

Installation Time |

25-35 min |

20 min |

Front |

|

Installation Complexity |

Moderate |

Simple |

Front |

|

Cassette Transfer Required |

Yes |

No |

Front |

|

Torque Arm Needed |

Yes (750W+) |

Rarely |

Front |

|

Steering Feel |

Natural |

Heavier |

Rear |

|

Cable Management |

Simpler |

Handlebar routing |

Rear |

|

Speed Capability |

Unlimited |

Limited |

Rear |

|

Reversibility |

Moderate |

Complete |

Front |

|

Professional Performance |

Excellent |

Good |

Rear |

When Rear-Wheel Excels

Optimal Applications:

Performance Priority: ✓ Power over 500W desired ✓ Speed capability important ✓ Hills regularly encountered ✓ Professional feel wanted ✓ Serious capability needed

Challenging Terrain: ✓ Steep sustained climbing ✓ Off-road trail riding ✓ Wet conditions common ✓ Loose surface navigation ✓ Traction critical

Heavy Loads: ✓ Cargo carrying regular ✓ Touring with panniers ✓ Heavy rider weight ✓ Trailer pulling ✓ Utility applications

Experienced Riders: ✓ Mechanical comfort adequate ✓ 25-35 minute installation acceptable ✓ Tools available ✓ Performance valued ✓ Quality prioritized

Maximizing Rear-Wheel Performance

Optimal Component Selection

Drivetrain Considerations:

Cassette Selection:

- Keep existing if good condition

- Upgrade to quality if worn

- Match gear range to terrain

- 8-11 speed typical

- Quality matters for longevity

Chain Requirements:

- May need longer chain

- Quality chain essential

- Proper tension critical

- Regular maintenance important

- Replace at 0.5-0.75% stretch

Derailleur Setup:

- Adjustment after installation

- Limit screws verified

- Cable tension proper

- Shifting smooth

- Professional tune helpful

Battery Selection Strategy

Matching Battery to Motor:

48V 1000W System:

- Battery: 48V 13-20Ah

- Range: 35-60km

- Application: Most riders

- Value: Excellent balance

52V 2000W System:

- Battery: 52V 20-30Ah

- Range: 40-80km

- Application: Performance focus

- Value: Superior power delivery

72V 4000W System:

- Battery: 72V 20Ah minimum

- Range: 40-80km

- Application: Extreme performance

- Value: Maximum capability

Maintenance Priorities

Critical Maintenance Areas:

Torque Arm Inspection:

- Monthly visual check

- Verify bolt tightness

- Look for frame damage

- No movement allowed

- Replace if damaged

Motor Axle Security:

- Check monthly

- Proper torque maintained (35-40 Nm)

- No loosening allowed

- Inspect regularly

Cassette and Chain:

- Chain stretch monitoring

- Cassette wear inspection

- Replacement as needed

- Quality components

- Proper lubrication

Brake System:

- Disc brakes recommended (1000W+)

- Pad wear monitoring

- Rotor condition checked

- Brake power adequate

- Upgrade if necessary

Rear-Wheel Selection Decision Framework

Choose Rear-Wheel Kit If:

Performance Requirements: ✓ Power over 500W wanted ✓ Speed over 35 km/h desired ✓ Hills regularly encountered ✓ Traction critical importance ✓ Professional feel valued ✓ Future power upgrades possible

Terrain Challenges: ✓ Steep sustained climbing ✓ Wet conditions common ✓ Off-road capability needed ✓ Loose surface navigation ✓ Heavy load carrying ✓ Varied terrain riding

Installation Readiness: ✓ 25-35 minute installation acceptable ✓ Basic mechanical skills present ✓ Tools available or obtainable ✓ Following instructions comfortable ✓ Cassette transfer manageable ✓ Learning opportunity welcomed

Rider Characteristics: ✓ Performance-focused mindset ✓ Serious cycling experience ✓ Quality and capability valued ✓ Long-term investment perspective ✓ Natural handling appreciated ✓ Professional results desired

Choose Front-Wheel Kit Instead If:

Conclusion

Rear-wheel e-bike conversion kits represent the optimal choice for performance-focused riders, challenging terrain applications, higher power requirements, and anyone prioritizing superior traction, natural handling, and professional feel over installation simplicity. The mid motor electric conversion kit excels for technical climbing efficiency, but rear-wheel systems deliver unmatched power capability (250-4000W), exceptional traction all conditions, and natural bicycle dynamics familiar to experienced cyclists.

Ready to experience professional e-bike performance through proven rear-wheel advantages? Explore the complete electric bike kit battery range including comprehensive rear-wheel systems with detailed specifications, installation guidance, torque arm requirements, and expert support ensuring your conversion delivers the exceptional traction, natural handling, and powerful performance only rear-wheel motors provide for demanding cycling applications.

Frequently Asked Questions

Why are rear-wheel conversion kits better than front-wheel for performance?

Rear-wheel motors deliver superior traction (power where weight concentrates), natural steering feel (front wheel unweighted), higher power capability (250-4000W vs 250-500W), and better climbing (weight transfers rearward).

How difficult is rear-wheel conversion kit installation compared to front-wheel?

Rear installation takes 25-35 minutes versus 20 minutes front, requiring cassette transfer (5 minutes with included tools), torque arm installation for 750W+ motors (5 minutes), and derailleur adjustment (5 minutes).

Do I really need torque arms with rear-wheel conversion kits?

Torque arms prevent motor axle rotation and catastrophic dropout damage: optional for 250-500W on steel frames but strongly recommended, mandatory for 750-1500W systems (one side minimum), absolutely required both sides for 2000W+ motors.

What's the maximum power level safe for rear-wheel conversion?

Steel and chromoly frames safely handle 4000W with proper torque arms and frame inspection. Aluminum frames suitable for 250-2000W with mandatory torque arms and regular monitoring.

How does rear-wheel motor affect bicycle handling and steering?

Rear-wheel motors maintain natural front-end steering feel (no added weight), create familiar rear-heavy balance similar to carrying panniers, and preserve responsive maneuvering characteristics experienced cyclists appreciate.