Long-distance bicycle touring demands exceptional endurance from both rider and equipment. When converting a touring bicycle to electric assist, specification priorities shift dramatically from casual commuting or weekend recreation.

Range anxiety, component reliability, and sustainable power delivery become paramount concerns that determine whether your multi-day adventure succeeds or strands you miles from civilization.Selecting the right e-bike conversion kit for touring requires understanding how motor characteristics, battery capacity, controller efficiency, and system weight collectively influence your ability to cover 50-100+ miles daily across varied terrain while carrying substantial gear.

The wrong specifications transform what should be an empowering journey into a frustrating experience of premature power depletion and mechanical complications.

Battery Capacity: The Foundation of Touring Range

Battery capacity represents the single most critical specification for long-distance touring applications. While urban commuters might succeed with compact 7-10Ah batteries, touring cyclists require substantially larger energy reserves to maintain confidence across extended unpopulated stretches.

Calculating Real-World Touring Range

Manufacturers often cite optimistic range figures based on minimal pedaling effort, flat terrain, and ideal conditions. Touring reality involves headwinds, loaded panniers, mountain passes, and rider fatigue—factors that dramatically increase energy consumption.

Realistic Range Calculation Formula:

- Base range (manufacturer specification)

- Terrain modifier: -25% for rolling hills, -40% for mountainous routes

- Load penalty: -15% for 20kg touring gear, -25% for 35kg+ loads

- Weather factor: -20% for persistent headwinds or cold temperatures

- Aging adjustment: -10% after 500+ charge cycles

A 48V 16Ah battery (768 watt-hours) might claim 60km range unloaded on flat terrain. Loaded touring through hilly terrain realistically delivers 30-40km before requiring recharge—adequate for supported touring with nightly accommodation but insufficient for multi-day wilderness expeditions.

Optimal Battery Specifications for Touring

|

Touring Style |

Minimum Capacity |

Recommended Capacity |

Voltage Platform |

Realistic Daily Range |

|

Credit card touring (hotels) |

48V 16Ah (768Wh) |

52V 20Ah (1040Wh) |

48-52V |

50-70km |

|

Supported touring (planned charging) |

48V 20Ah (960Wh) |

52V 25Ah (1300Wh) |

48-52V |

60-90km |

|

Self-contained touring |

52V 25Ah (1300Wh) |

52V 30Ah (1560Wh) |

52V |

70-100km |

|

Expedition touring |

52V 30Ah (1560Wh) |

Dual battery system |

52-60V |

100-140km |

KirbEbike's battery collection includes high-capacity LG-cell packs suitable for touring demands. The 52V 30Ah configuration provides 1560 watt-hours—sufficient for most single-day touring segments even under challenging conditions.

Battery Mounting Considerations for Loaded Touring

Touring bicycles carry substantial weight in panniers, frame bags, and handlebar rolls. Battery placement affects weight distribution and handling characteristics:

Down Tube Mounting (Preferred for Touring):

- Centralizes weight for optimal handling

- Protects battery from pannier interference

- Maintains low center of gravity with loaded rear rack

- Requires adequate frame triangle clearance

Rear Rack Mounting (Alternative):

- Practical for smaller frame geometries

- Positions weight over rear wheel for traction

- May interfere with pannier attachment

- Elevates center of gravity when combined with gear

Weight distribution matters tremendously on loaded touring bicycles. Front panniers, rear panniers, frame bags, and battery should collectively balance around the bicycle's center to maintain neutral handling. A rear-mounted battery combined with heavy rear panniers creates handling problems during low-speed technical sections.

Motor Selection: Efficiency vs. Power for Distance

Motor specifications for touring prioritize sustained efficiency over peak power output. Unlike urban systems that emphasize acceleration and hill-climbing bursts, touring motors operate continuously at moderate power levels for hours.

Geared Hub Motors vs. Direct Drive for Touring

Geared Hub Motor Advantages:

- Superior efficiency at touring speeds (15-25 km/h)

- Lower power consumption per kilometer

- Reduced weight (typically 2.7-4.5kg vs. 5-7kg for direct drive)

- Better hill-climbing efficiency at lower speeds

- Allows coasting without motor drag

Direct Drive Hub Motor Advantages:

- Exceptional durability with no internal gears to wear

- Better heat dissipation during sustained climbs

- Regenerative braking potential (minor benefit for touring)

- Handles sustained high loads without overheating

- Simplified maintenance with fewer moving parts

For most touring applications, geared hub motors deliver superior overall efficiency. The 500-750W SHENGYI geared motors in KirbEbike's touring-appropriate kits provide optimal balance—sufficient power for loaded climbing while maintaining excellent efficiency during cruising.

Mid-Drive Systems for Touring Applications

Mid-drive conversion kits offer distinct advantages for touring cyclists prioritizing versatility:

Touring Benefits of Mid-Drive Systems:

- Utilizes bicycle's existing gearing for optimal efficiency across terrain

- Maintains ideal motor RPM regardless of road speed

- Distributes weight centrally for superior handling

- Allows standard wheel removal for tire/tube changes

- Reduces unsprung weight compared to hub motors

Mid-Drive Touring Considerations:

- Increased drivetrain wear (chain, cassette, chainrings)

- Requires carrying spare drivetrain components

- More complex maintenance and adjustment

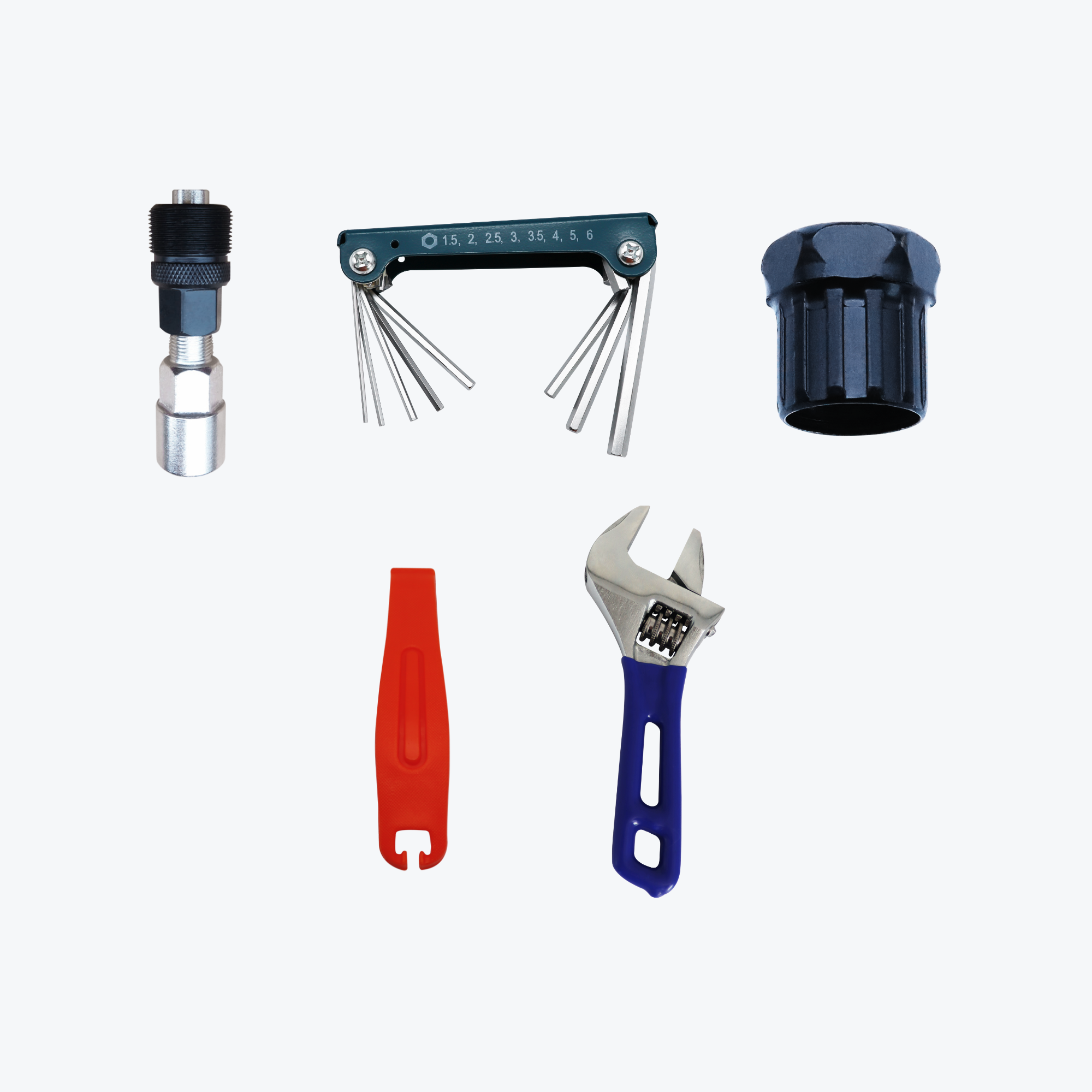

- Potential for mid-tour mechanical issues requiring tools

The Tongsheng TSDZ8 mid-motor systems in KirbEbike's lineup deliver 140Nm torque with torque-sensor pedal assist—providing natural touring feel while maximizing range through efficient power matching to rider input.

Controller and Display Features for Extended Journeys

Modern FOC (Field-Oriented Control) controllers dramatically improve touring viability through precise power management and comprehensive system monitoring.

Essential Controller Features for Touring

Power Management Capabilities:

- Multiple assist levels (minimum 3-5 discrete settings)

- Programmable power limits for range extension

- Temperature monitoring and thermal protection

- Low-voltage cutoff to preserve battery health

- Current limiting for sustained climbing

Reliability Features:

- IP65+ waterproof rating for weather exposure

- Robust connector systems resistant to vibration

- Overcurrent and short-circuit protection

- Regenerative capability (if using compatible motors)

KirbEbike's intelligent FOC controllers provide touring-essential features including real-time power consumption monitoring, allowing riders to calculate remaining range based on actual consumption patterns rather than estimates.

Display Information Critical for Touring

Required Display Metrics:

- Real-time speed and distance

- Battery voltage and remaining capacity percentage

- Watt-hour consumption (total and per-kilometer average)

- Assist level indication

- Estimated range remaining

- Trip computer with multiple trip memories

Advanced Touring Features:

- Average speed calculation

- Maximum speed recording

- Total system mileage

- Battery health indicators

- Error code display for troubleshooting

The TFT color displays included with KirbEbike conversion kits provide comprehensive ride data, enabling informed power management decisions during extended tours. Understanding real-time consumption helps optimize assist levels to reach planned destinations or charging opportunities.

Weight Considerations and Load Capacity

Touring bicycles regularly carry 15-35kg of gear, camping equipment, food, and water. Conversion kit specifications must account for substantially higher system loads than urban applications.

Component Weight Analysis for Touring

|

Component |

Lightweight Option |

Standard Option |

Heavy-Duty Option |

|

Motor (hub) |

2.7kg (250W geared) |

4.5kg (750W geared) |

6.8kg (2000W+ direct) |

|

Battery |

2.5kg (36V 13Ah) |

3.8kg (48V 16Ah) |

5.2kg (52V 30Ah) |

|

Controller |

0.3kg |

0.5kg |

0.7kg |

|

Display/wiring |

0.4kg |

0.5kg |

0.6kg |

|

Total system |

5.9kg |

9.3kg |

13.3kg |

Adding 9-13kg to a touring bicycle already carrying substantial gear requires careful specification selection. The 500-750W systems with moderate battery capacity represent optimal compromise—sufficient power and range without excessive weight penalty.

Frame and Component Stress Factors

Electric assist amplifies forces throughout the bicycle's structure. Touring-appropriate conversions must consider:

Frame Stress Points:

- Rear dropout strength (hub motor installations)

- Bottom bracket shell integrity (mid-drive systems)

- Down tube mounting bosses (battery attachment)

- Fork dropout alignment (front hub applications)

Component Upgrade Requirements:

- Heavy-duty wheel rims and spokes

- High-quality brake systems (hydraulic disc preferred)

- Reinforced rear rack rated for motor and battery weight

- Quality drivetrain components for mid-drive systems

Touring with electric assist while fully loaded demands components designed for the combined stresses. Budget conversions using minimal components invite mechanical failures during remote sections of tours.

Charging Infrastructure Planning for Tours

Unlike daily commuting with predictable charging access, touring requires strategic planning around charging opportunities and backup power solutions.

Charging Speed and Flexibility

Standard Charger Specifications:

- 36V systems: 2A chargers (4-6 hour full charge)

- 48V systems: 2A chargers (5-8 hour full charge)

- 52V systems: 2A chargers (6-10 hour full charge)

Fast Charging Considerations:

- 5A chargers reduce charging time by 60%

- Accelerated charging increases battery temperature

- Frequent fast charging reduces long-term battery lifespan

- Essential for tight touring schedules with limited charging windows

Multi-Voltage and International Charging

KirbEbike chargers support UK, EU, US, and Australian plug standards—critical for international touring. Verify charger voltage compatibility (110-240V input) before international trips to avoid requiring voltage converters.

Solar Charging for Expedition Touring

Extended wilderness touring may necessitate solar charging capabilities:

Solar System Requirements:

- Minimum 100W solar panel for practical charging rates

- MPPT charge controller compatible with lithium batteries

- MC4 to battery adapter cable

- Realistic expectation: 10-15% daily battery replenishment in good conditions

Solar charging serves as emergency backup rather than primary power source for most touring applications. Full battery replenishment via solar requires multiple days of ideal conditions.

Optimizing Assist Settings for Maximum Touring Range

Even excellent specifications underperform without proper assist level management. Strategic power usage extends range dramatically while maintaining comfortable progress.

Assist Level Strategy for Different Terrain

Flat Sections (Assist Level 1-2):

- Minimal electrical assistance

- Rider provides majority of power

- Maximizes range per watt-hour

- Maintains reasonable speed (20-25 km/h)

Rolling Hills (Assist Level 2-3):

- Moderate assistance on climbs

- Reduce to minimal assist on descents

- Balance between comfort and efficiency

- Average 25-30 km/h depending on grade

Sustained Climbs (Assist Level 3-4):

- Higher assistance preventing rider fatigue

- Accept higher power consumption for progress

- Monitor battery carefully during extended climbs

- Consider walking extremely steep sections to preserve battery

Conclusion

Selecting an e-bike conversion kit for long-distance touring demands prioritizing specifications that support extended range, exceptional reliability, and serviceable design over raw performance metrics. Battery capacity, motor efficiency, weather resistance, and weight considerations collectively determine whether your converted touring bicycle enhances or

The KirbEbike conversion kit range provides touring-appropriate specifications across multiple power and battery configurations, ensuring you can match system capabilities to your specific touring ambitions—whether weekend credit card tours or month-long self-contained expeditions through remote regions.

Frequently Asked Questions

What battery capacity do I need for 100km touring days?

For loaded touring covering 100km daily, target minimum 52V 25-30Ah capacity (1300-1560 watt-hours). This provides comfortable reserves even with headwinds, hills, and heavy loads, preventing range anxiety during remote sections.

Are hub motors or mid-drive systems better for touring?

Both work well but serve different priorities. Geared hub motors offer simplicity and lower maintenance; mid-drives provide better efficiency on varied terrain and allow easier wheel removal for repairs. Choose based on tour terrain and mechanical confidence.

How much weight does a touring conversion add to my bicycle?

Complete touring-appropriate systems add 9-13kg depending on battery capacity. A 48V 16Ah system adds approximately 9kg; 52V 30Ah systems add 12-13kg. This represents significant added weight requiring proper weight distribution and component upgrades.

Can I charge my e-bike battery at campgrounds?

Most developed campgrounds provide electrical outlets at tent sites or common areas. Standard 2A chargers draw minimal power (100-150W) and rarely create issues. Always request permission and offer compensation for extended charging sessions.

What happens if my conversion kit fails during a remote tour?

Geared hub motors allow relatively normal pedaling if electrical systems fail. Carry basic spare parts (connectors, fuses), diagnostic tools (multimeter), and be prepared to complete tours unpowered if necessary. Design tours with mechanical failure contingencies.

Should I carry a spare battery for extended wilderness touring?

Spare batteries double your range but add 3-5kg weight and considerable expense. For supported touring, single high-capacity battery suffices; for multi-day wilderness sections without charging, dual battery systems or solar backup becomes advisable.

How do I protect electrical components during multi-day rain?

Beyond IP65 ratings, apply silicone sealant to connector interfaces, use frame bags to shield battery terminals, inspect connections daily, and apply dielectric grease. Consider removable waterproof covers for display units during sustained downpours.